3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

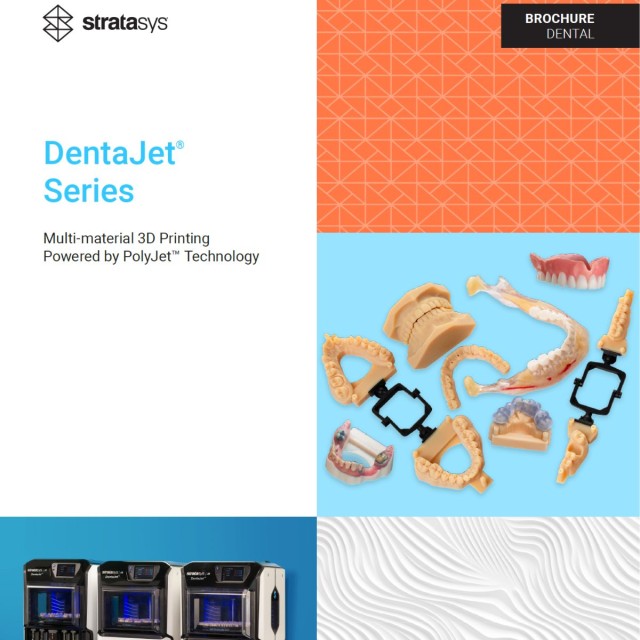

The Stratasys® DentaJet® XL is a breakthrough high-speed 3D printer created exclusively for high-volume dentistry labs, enabling unparalleled efficiency and cost-effectiveness in dental model production.

The Stratasys® DentaJet® XL is an advanced 3D printer developed to suit dentistry laboratories' high-volume production requirements. Building on the success of the J5 DentaJet®, the XL model has a much larger capacity, allowing for the printing of up to 102 models in a single run. It has larger resin cartridges and a larger print tray, allowing for longer uninterrupted print sessions and minimizing the number of material changes.

The DentaJet® XL features a "Super High-Speed" mode, which increases production in dental labs. Furthermore, it keeps a sealed resin environment, eliminating the requirement for isopropyl alcohol (IPA) in post-processing, resulting in a safer, cleaner working environment free of hazardous odours. This printer combines high throughput with Stratasys®' well-known precision and multi-material capabilities, making it a great solution for dental labs wanting to increase production of a variety of dental applications including as models, surgical guides, and aligner molds.

Technical Specifications:

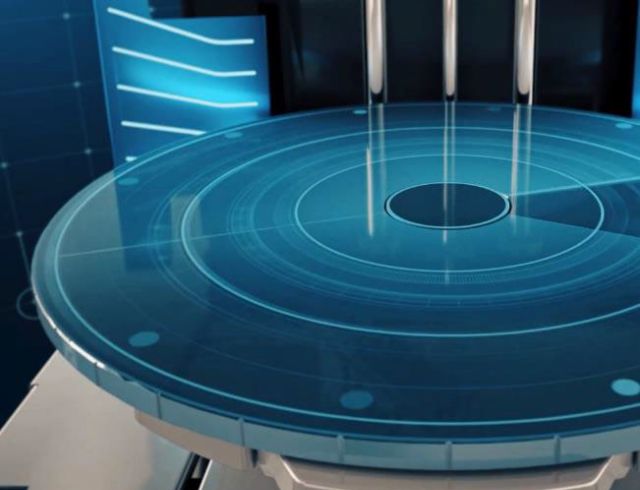

Tray Size and Area: Round print tray with up to 1,174 cm²

Print Height: 187 mm

Layer Thickness: 20.625 μm - 61.875 μm

The DentaJet® XL comes with two build modes depending on your time-constraints and the acceptable quality you need. High Quality High Speed (HQHS) Build Mode enables 20.625 μm accuracy with the best detail printable and Super High Speed (SHS) Build Mode enables 61.875 μm accuracy (for aligner arches only) with minimal degradation to print quality.

Print Capacity:

- Up to 102 crown and bridge models in 4 hours 31 minutes (using HQHS mode)

- Up to 36 aligner arches in 2 hours 13 minutes (using SHS mode)

- Up to 28 orthodontic models in 6 hours 37 minutes (using HQHS mode)

- Up to 16 implant cases in 6 hours 30 minutes (using HQHS mode)

The DentaJet® XL has a cartridge capacity of 4 kg. When compared to the J3 DentaJet and the J5 DentaJet, they both only have a cartridge capacity of 1.1 kg which is more or less only one fourth of the cartridge capacity of the DentaJet® XL.

The 360-degree print tray's huge capacity of 1,174 cm² enables the manufacturing of more parts in greater quantities. Small- to large-sized dental labs benefit from the compact footprint, which increases productivity.

In a single mixed-tray print, produce dental parts using mixed materials. The DentaJet® XL can print up to two multiple materials simultaneously. Minimise the amount of printers or processes required to finish a task.

With the DentaJet® XL, you can print with high resolution droplets and complete curing during printing, which removes distortions from post-processing and gives your components unparalleled accuracy.

Having a sealed resin environment eliminates the requirement for isopropyl alcohol (IPA) in post-processing, resulting in a safer, cleaner working environment free of hazardous odours. Also, the risks of accidental spills or skin contact with uncured resin is reduced.

Sealing the print area in addition helps to maintain constant temperature and humidity for more consistent prints and limits the possibility of dust or debris entering the resin tank and compromising print quality.

Operating GrabCAD Print™ requires very little training. Automatic print arrangement can boost output while cutting down on print time. Prior to printing, determine how much time and material will be required for production. Print jobs can be scheduled and tracked remotely. Without requiring the use of external software, automatically correct files and send alerts when the work is printing and finished.

Call or email us and we will be happy to help you.

Your cost-effective solution for consistent, high-volume implantology case production, including implant models and surgical guides. Print up to 16 implant cases in 6.5 hours.

Produce massive quantities of high-quality, accurate crown and bridge models while minimizing remakes. Print as many as 102 models in 4.5 hours.

Increase your lab's capacity with Super High Speed printing of precise aligner arches. Print up to 36 arches in around 2 hours.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy