3D printers

High quality 3D printers

High-quality 3D printing solutions for demanding projects

Order Parts now!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

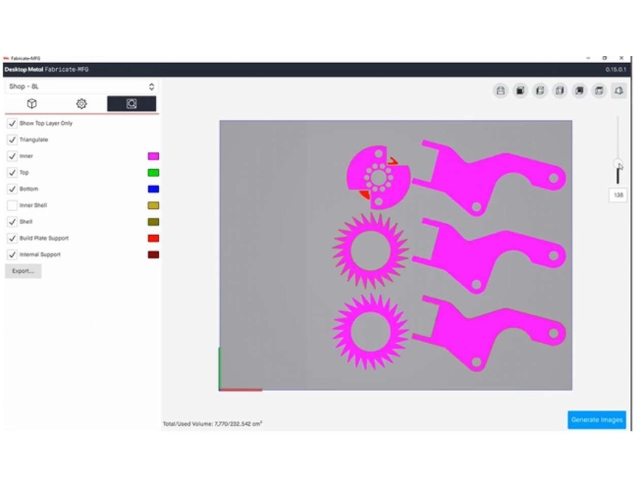

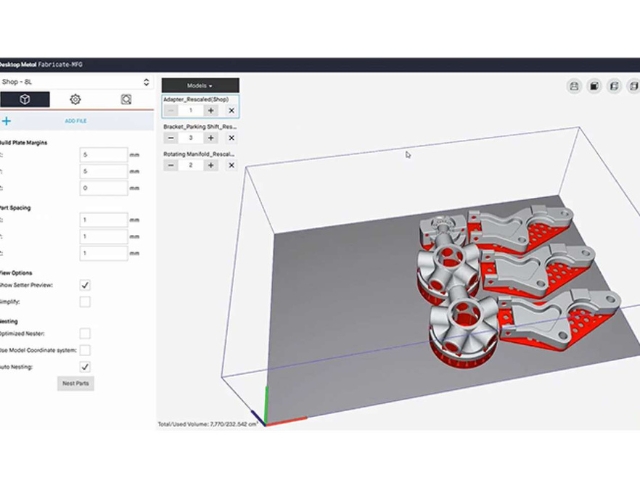

With Fabricate MFG, also known as Live Build™ MFG, users get a complete solution for preparing files for the Desktop Metal® Binder Jetting 3D printer. The software is intuitive and allows the vast majority of functions to be carried out with a single click.

This software makes the additive manufacturing of metal components more flexible and efficient, without the need for highly trained operators or extensive training.

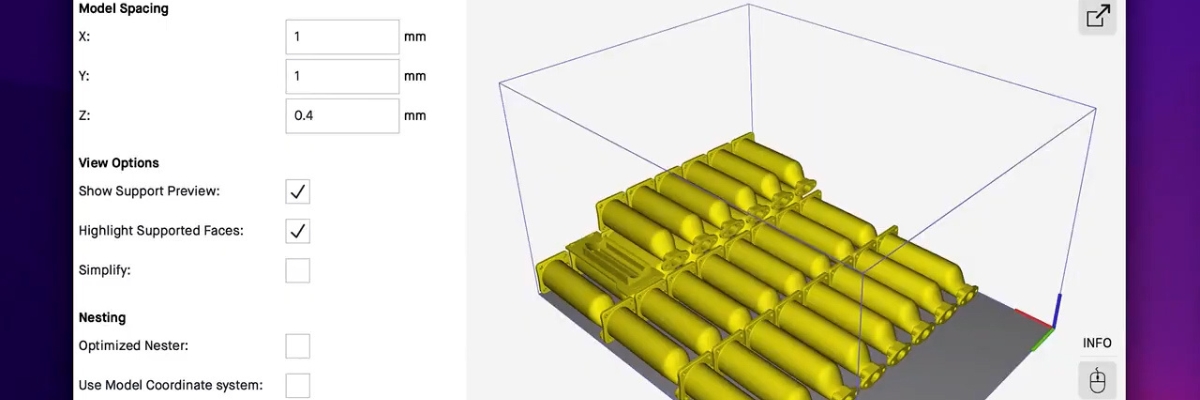

Users simply insert their digital model into the Fabricate MFG or Live Build™ MFG software and it will do the print preparation work for them. The software automatically arranges the individual parts in the best possible way in the available 3D space to maximize the use of the build plate. Users can add further parts simply by pressing a button, and the software will also place these parts ideally on the build plate.

With the Fabricate MFG or Live Build™ software, users can use the automatic slicing function to quickly break down the component into data that the printer can use. The software creates an interactive preview so that users can get a detailed understanding of the internal structure of the part, while they can display layer-by-layer views of the structure or triangulated sections to check the wall thickness, for example.

The shrinkage and distortion of the component that occurs during the sintering process is minimized by the use of so-called sintering supports. With the Fabricate MFG or Live Build MFG™ software, these sintering supports can be automatically adapted to the respective component geometry, the material used and individual scaling factors to ensure sintering success.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy