3D printers

High quality 3D printers

High-quality 3D printing solutions for demanding projects

Order Parts now!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

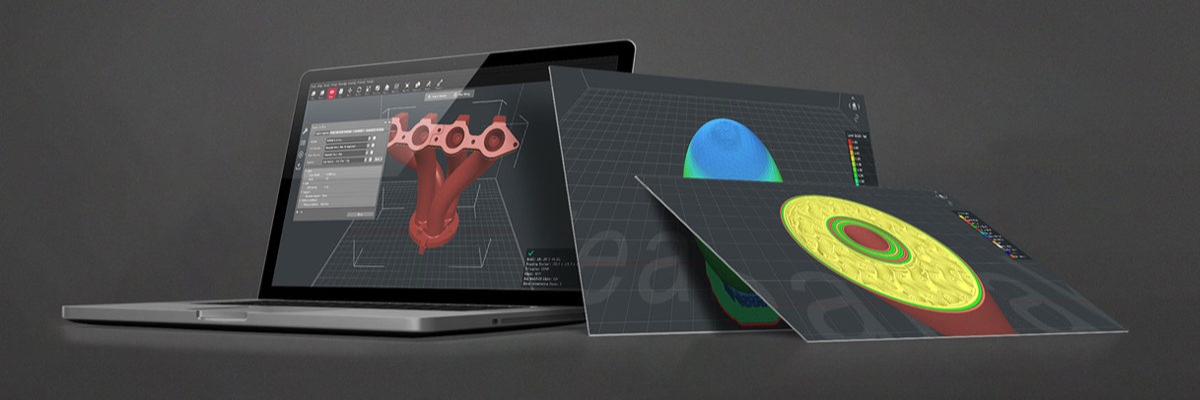

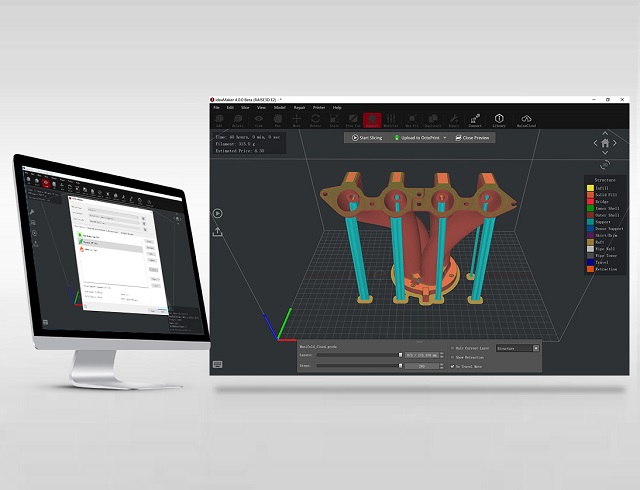

The ideaMaker software developed by Raise3D is compatible with all Raise3D 3D printers. It is one of the most feature-rich slicer softwares on the market and is also very user-friendly. This combination makes ideaMaker perfect for both beginners and professionals.

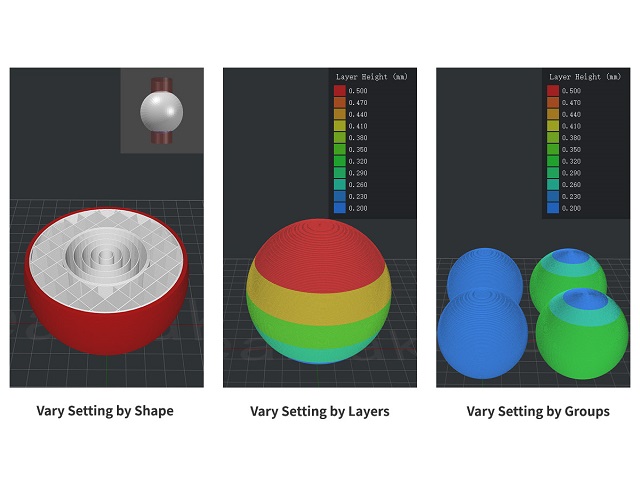

The laborious process of slicing is highly automated by the automatic parameters in the Raise3D ideaMaker software. Using complex and proven algorithms, parameters such as layer height and infill structure are automatically calculated, ensuring maximum surface quality while reducing material consumption.

Instead of manually checking and tweaking a wide range of settings, users of the Raise3D ideaMaker software can use automatic optimization to massively simplify and speed up the slicing process.

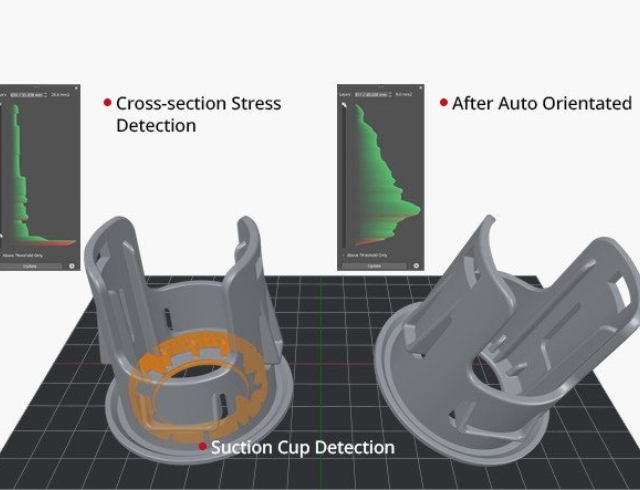

The Raise3D ideaMaker software automatically detects potential failure risks and provides easy-to-implement suggestions for minimizing these risks. In addition, the software offers automatic alignment of the component, thus eliminating another common source of defects caused by uneven clamping forces or unwanted cavity structures.

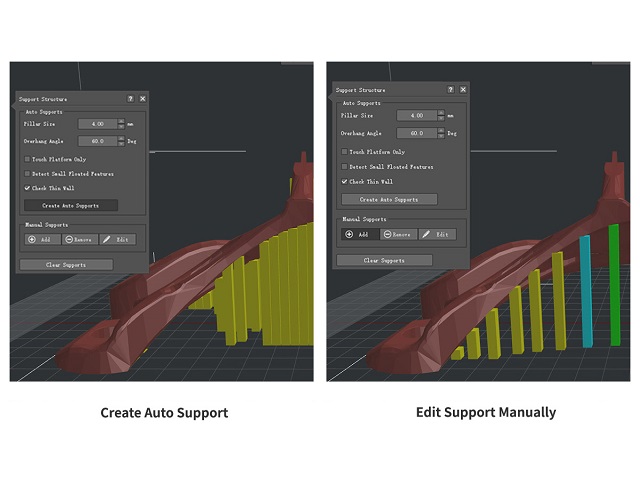

The Raise3D ideaMaker software can automatically generate support structures customized for the respective component, completely relieving users of this step. If needed, users can also use the integrated tools to customize the support structures.

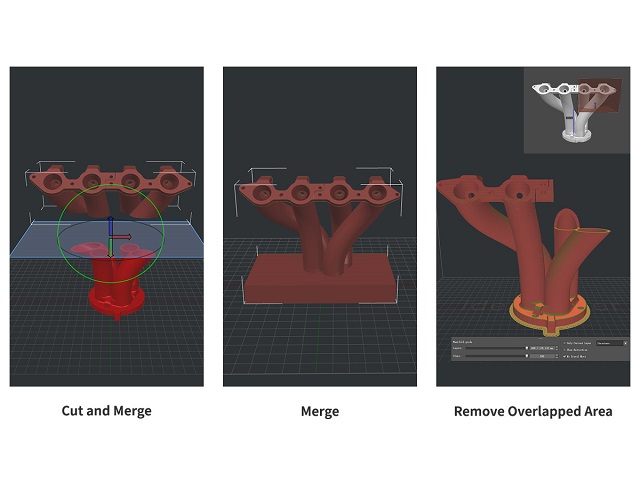

Users can also use Boolean tools in the Raise3D ideaMaker software to model parts, combine them and cut off overhangs, for example. These tools are very easy to use in ideaMaker and are ideal for making final model adjustments without having to switch back to a CAD software.

The entire printing process can be visualized in a simulation to provide users with important data on print speed, layer heights, extruder movements and much more. This simulation is also compatible with independent double extruders to provide a realistic preview.

The Raise3D ideaMaker software offers several patterns that allow users to quickly and easily create concave or convex surfaces on their components based on the grayscale values of an image. The user can then customize the texture parameters to suit their needs by adjusting the settings.

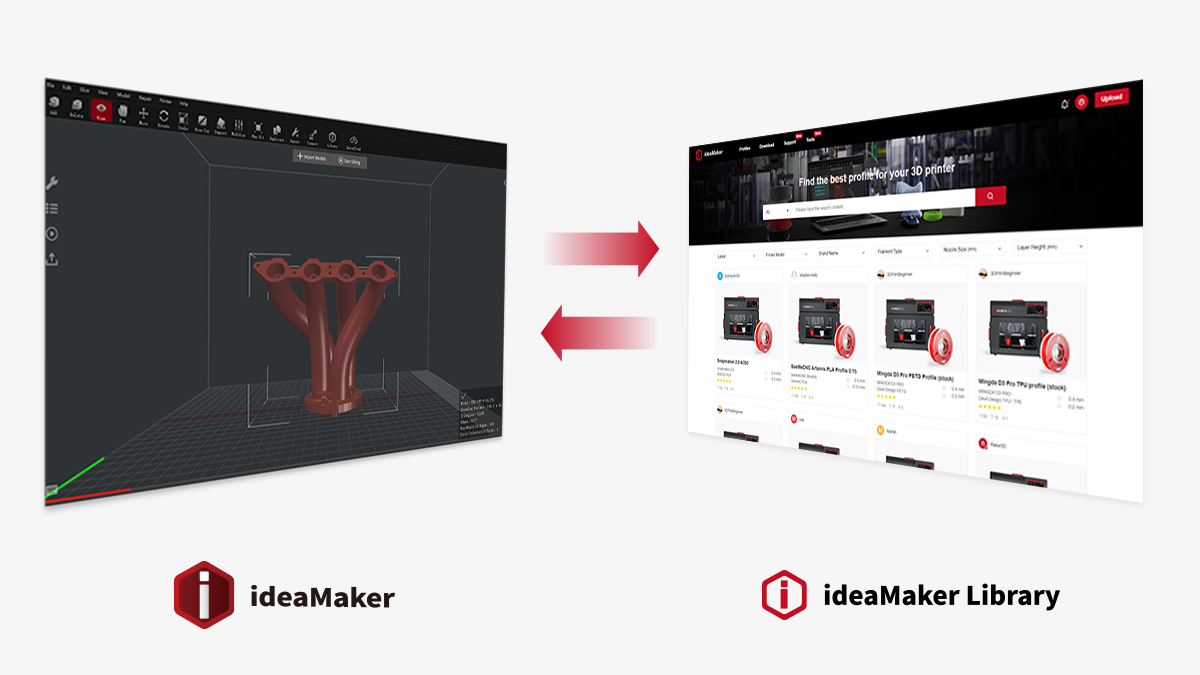

The ideaMaker software is compatible with the entire Raise3D ecosystem. This gives users access to free slicing profiles for a wide range of filaments and allows them to get in touch with the entire Raise3D community to exchange tips and get answers to their questions.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy