3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

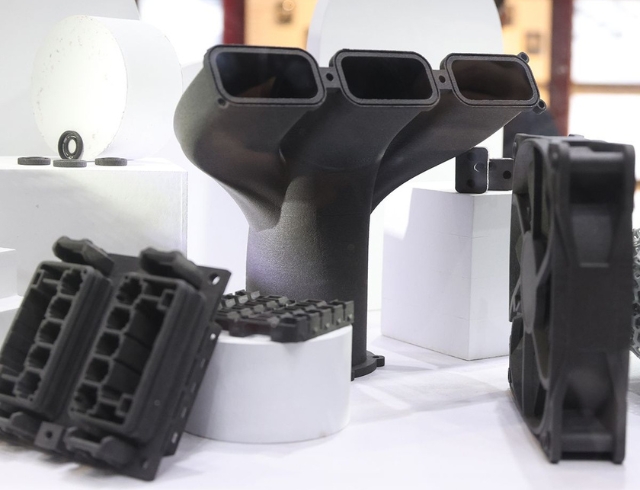

The Raise3D RMS220 is an industrial-grade Selective Laser Sintering (SLS) 3D printer engineered for high productivity, reliability, and cost-effectiveness in manufacturing environments.

Featuring a spacious build volume of 220 × 220 × 350 mm, the RMS220 is capable of producing up to 5 kg of parts per day using powders, making it ideal for batch production and rapid prototyping. Its 75 W fiber laser and advanced 4-zone self-calibrating infrared heating system ensure consistent, high-precision results with an accuracy of ±0.2 mm and a minimum wall thickness of 0.5 mm (in thin-wall mode with technical support). The system supports a range of engineering plastics and composites, including PA12, PA11, TPU90A, and PA12 GB powders, and achieves print speeds up to 2.2 L/h at 20% packing density.

The RMS220 was created with user-friendliness and operational efficiency in mind. Its quick-change powder system and modular build chamber cut down material swap times to 45 minutes, greatly reducing downtime between projects. By automating powder identification and configuration using RFID material management, it lowers the possibility of material mix-ups and guarantees traceable, repeatable quality. The RMS220 is compatible with Raise3D’s ideaMaker slicing software and supports a variety of industry-standard file formats, making it a versatile solution for demanding applications that require tight tolerances and fine details.

Technical data:

Build Volume: 220 x 220 x 350 mm

Laser: 75 W fiber laser, wavelength 1064 nm

Layer Height: 0.05 - 0.50 mm

Printing Speed: 2.2 L/h (packing density 20% by weight)

With a 75 W fiber laser and a high-precision galvanometer that can scan at up to 30,000 mm/s, the RMS220 makes use of cutting-edge Selective Laser Sintering (SLS) technology. With this configuration, the printer can print thin walls as small as 0.5 mm (in thin-wall mode with technical help) and produce remarkable detail and accuracy with a dimensional precision of ±0.2 mm. Significant benefits come from SLS technology itself: complicated geometries can be created without the need for extra structures because the unfused powder serves as a natural support. Users can thus create functioning parts and complex prototypes with smooth surfaces and precise details, satisfying the exacting requirements needed for industrial applications.

The RMS220 is unique among entry-level industrial SLS printers because of its ability to handle both big individual components and batch production runs, with a build volume of 220 × 220 × 350 mm (17 liters). Rapid prototyping and low-volume manufacturing requirements are supported by the printer's ability to produce up to 5 kg of components per day (using PA12 at 20% packing density). It can print up to 2.2 liters per hour, and by packing the entire build space full of pieces, throughput may be maximized. The RMS220 is appropriate for a range of industrial settings because of its small footprint (only 0.58 square meters), which guarantees that this efficiency does not come at the expense of important floor space.

The RMS220's four-zone, self-calibrating infrared (IR) heating system is one of its unique features. In order to minimize warping and dimensional deformation during the sintering process, this technique makes sure that the temperature is distributed uniformly across the construction platform. Regardless of part placement, the printer produces homogeneous material qualities and highly repeatable outputs by maintaining constant heat conditions throughout the construction. For sectors that require parts with strict tolerances and consistent quality across batches, this dependability is essential.

With its quick-change powder system and modular build chamber, the RMS220 is built for operating efficiency. This reduces the time needed by standard SLS machines by approximately one-third, enabling users to swap SLS powder materials in as little as 45 minutes. The system is designed to be simple to clean, removing locations that are difficult to access and lowering the amount of work needed to switch out materials. For facilities that must regularly switch out materials or colors, this flexibility is especially helpful because it allows them to react swiftly to shifting production demands without experiencing prolonged downtime.

To facilitate smooth material management, Raise3D incorporates RFID technology into the RMS220. The printer streamlines the setup procedure and lowers the possibility of material mix-ups or human error by automatically detecting and configuring the powder material loaded. Because the right parameters are always applied for every material batch, this automation not only improves user comfort but also guarantees traceability and consistent print quality. In controlled or quality-sensitive manufacturing settings, the RFID system is essential to upholding high standards.

The RMS220 is adaptable for a variety of applications since it can work with a broad range of engineering-grade thermoplastics and composites, such as PA12, PA11, TPU90A, and PA12 GB powders. Raise3D's ideaMaker slicing software, which is fully integrated with the printer, makes it easier to position models, optimize packing, and make effective use of build volume in order to cut down on material waste and print times. It is compatible with the majority of CAD workflows and allows for a smooth integration into current design and manufacturing processes by accepting a number of industry-standard file formats, including STEP, STP, OBJ, 3MF, OLTP, IGES, and IGS.

The Raise3D RMS220 is equipped with a comprehensive suite of security features designed to protect both the device and sensitive production data. Secure settings and password protection, SSH (Secure Shell) access, lock screen functionality and even controlled export of local print files and credential data to external storage devices, with export permissions managed by the administrator. Complementing these digital security measures, the RMS220 integrates safety innovations such as power loss recovery, automatic door detection, thermal management safeguards, user interface warnings and guided maintenance routines.

Iterate quickly on enclosure designs, gear assemblies, or even snap-fit features, validating performance under real-world conditions and reducing the risk of costly design errors.

Produce complex, lightweight geometries that are difficult to achieve with traditional manufacturing such as functional housings, brackets, and connectors used in automotive or consumer electronics.

Print for example a batch of inspection jigs for quality control or custom assembly fixtures to streamline complex workflows, reducing both lead times and costs compared to traditional machining

Produce flexible, impact-resistant, and durable parts for specialized applications such as gaskets, seals, protective covers, or wearable device components that require elasticity and resilience.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy