3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

With up to 50% faster print speeds and improved durability than its predecessor, the Stratasys® Neo®800+ is a large-format SLA 3D printer that is perfect for creating precise, industrial-grade parts for demanding applications.

With an emphasis on speed, dependability, and material compatibility, the Stratasys® Neo®800+ offers a number of noteworthy improvements over the original Neo®800. The innovative ScanControl+™ technology, which maximizes laser scanning and energy delivery to increase print rates by up to 50% over its predecessor, is one of the most notable features. Time-to-part is significantly decreased as a result; benchmarks indicate average improvements of 39% and, depending on the material, up to 44% for tooling molds. High part authenticity is ensured and post-processing is much reduced because of the improved laser and optics system, which also supports high-energy materials and produces smoother surfaces and clearer details.

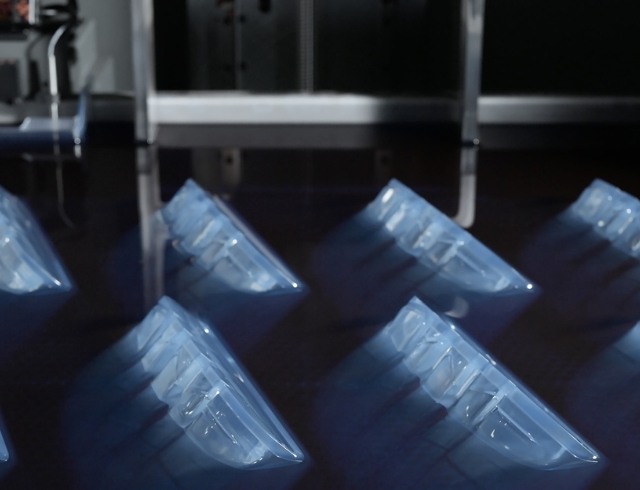

The Neo®800+ includes cutting-edge reliability features including Vacuum System Protection, Z-Stage Collision Detection, and real-time environmental monitoring in addition to speed and surface quality. In tough industrial settings, these enhancements guarantee consistent, high-quality output and boost machine uptime. Additionally, the printer is tailored for ScanControl+ Ready Materials, such as the Somos® WaterShed® XC+, which is made to scan more quickly without sacrificing optical clarity or smooth finishes.

Specifications:

Laser: 4 Watt, 355 nm, solid-state frequency tripled Nd:YVO4

Beam focus: Dynamic & variable

Beam size: 120 to 750 μm

Layer thickness: 50 to 200 μm

Build volume: 800 × 800 × 600 mm

The Stratasys® Neo®800+ greatly improves printing speed and accuracy with its redesigned scanning system and powerful 4-watt laser. With its dynamic and variable beam focus spanning from 120 to 750 µm, this improved laser operates at 355 nm, enabling faster scanning speeds of up to 790 in./s (20 m/s). The Neo®800+ can produce components with sharp edges, smooth surfaces, and excellent dimensional accuracy because of its wider beam size range, which facilitates both quick scanning and superb fine detail reproduction. With up to 50% quicker print speeds than the previous Neo®800 model, this power and precision combination significantly increases throughput without sacrificing quality.

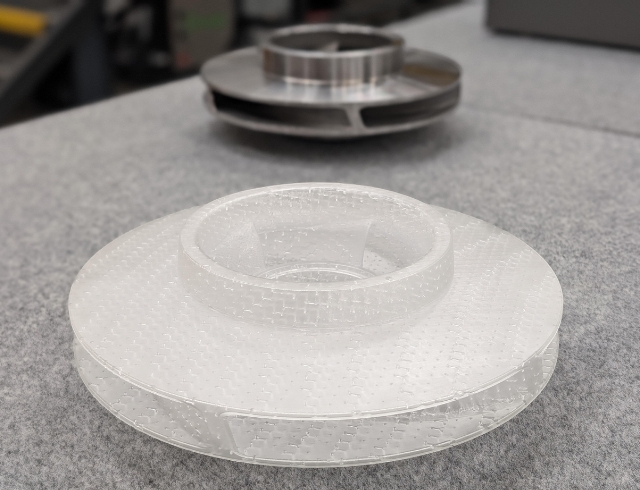

ScanControl+ technology, a sophisticated system that optimizes energy delivery and print sharpness by adjusting laser power, movement, and focus, is another important feature. By distributing energy evenly throughout the build area, this method improves part fidelity and lessens the need for post-processing. Additionally, ScanControl+ makes it possible for the Neo®800+ to function flawlessly with materials that are certified ScanControl+ ready, including Somos® resins, which are specifically designed to match the speed and precision capabilities of the printer. The Neo®800+ is appropriate for industrial-grade prototyping, tooling, and master patterns because of the hardware and material synergy that ensures first-time print success, dependable performance, and remarkable component precision.

Additionally, the Neo®800+ has improved safety and dependability measures that reduce downtime and safeguard the machine and its components during the construction process. These include Z-Stage Collision Detection, which guards against mechanical damage by identifying possible collisions during printing, and Vacuum System Protection, which protects the resin vat environment. Consistent quality and a longer machine lifespan are facilitated by real-time environmental monitoring, which guarantees ideal working conditions. The Neo®800+ is a reliable option for demanding production workflows because of these enhancements, which result in increased uptime and reduced maintenance requirements.

The Neo®800+ offers customers material versatility and freedom from proprietary restrictions by supporting an open resin system that works with all commercially available 355 nm stereolithography resins. Enormous parts can be printed in one piece or in numerous parts at once thanks to the enormous build volume of 800 × 800 × 600 mm, which saves time and lowers assembly costs.

The Neo®800+ uses cutting-edge software to improve and expedite each step of the stereolithography (SLA) process, most notably GrabCAD Print for Neo and the included Titanium print preparation suite. With only a few clicks, users can import CAD files, optimize component orientation, and create supports automatically with GrabCAD Print for Neo's unified, user-friendly platform for handling build preparation. Both regular and professional versions of the software are supported; the Pro tier adds sophisticated functionality including component labeling, segment and split tools for large parts, wall thickness and gap analysis, and manufacturing notes for thorough traceability.

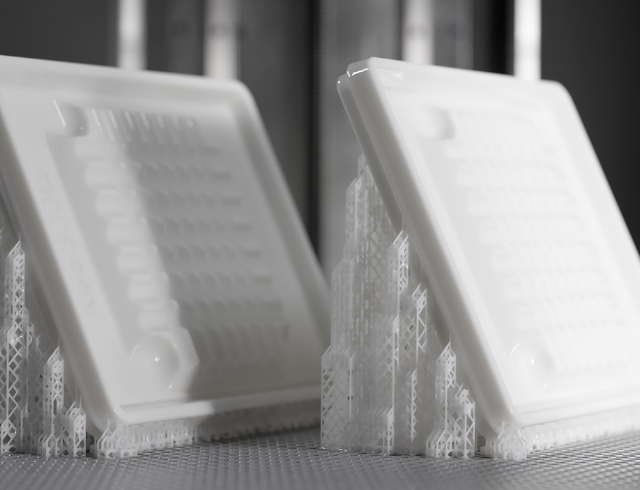

Perfect for functional fit-and-form designs, as well as precise, in-depth concept and communication models.

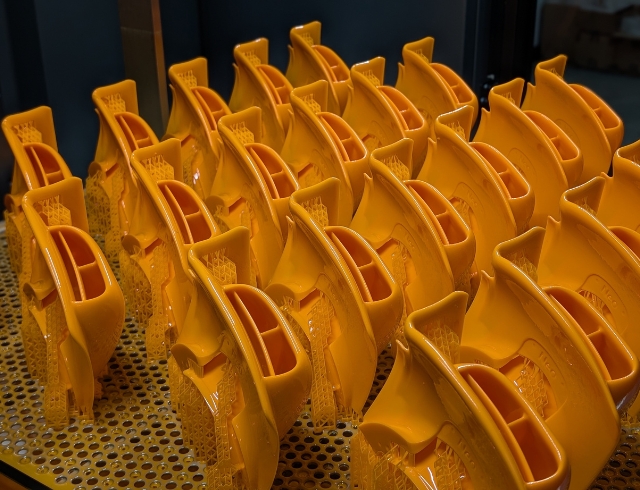

Increase output with quick, dependable, high-precision tools and molds that maintain the efficiency of your company.

For more than simply prototypes! Create strong, long-lasting components with intricate designs, smooth surfaces, and production-ready strength for particular situations.

Quickly produce master patterns of superior quality with intricate designs and flawless, accurate surfaces.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy