3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

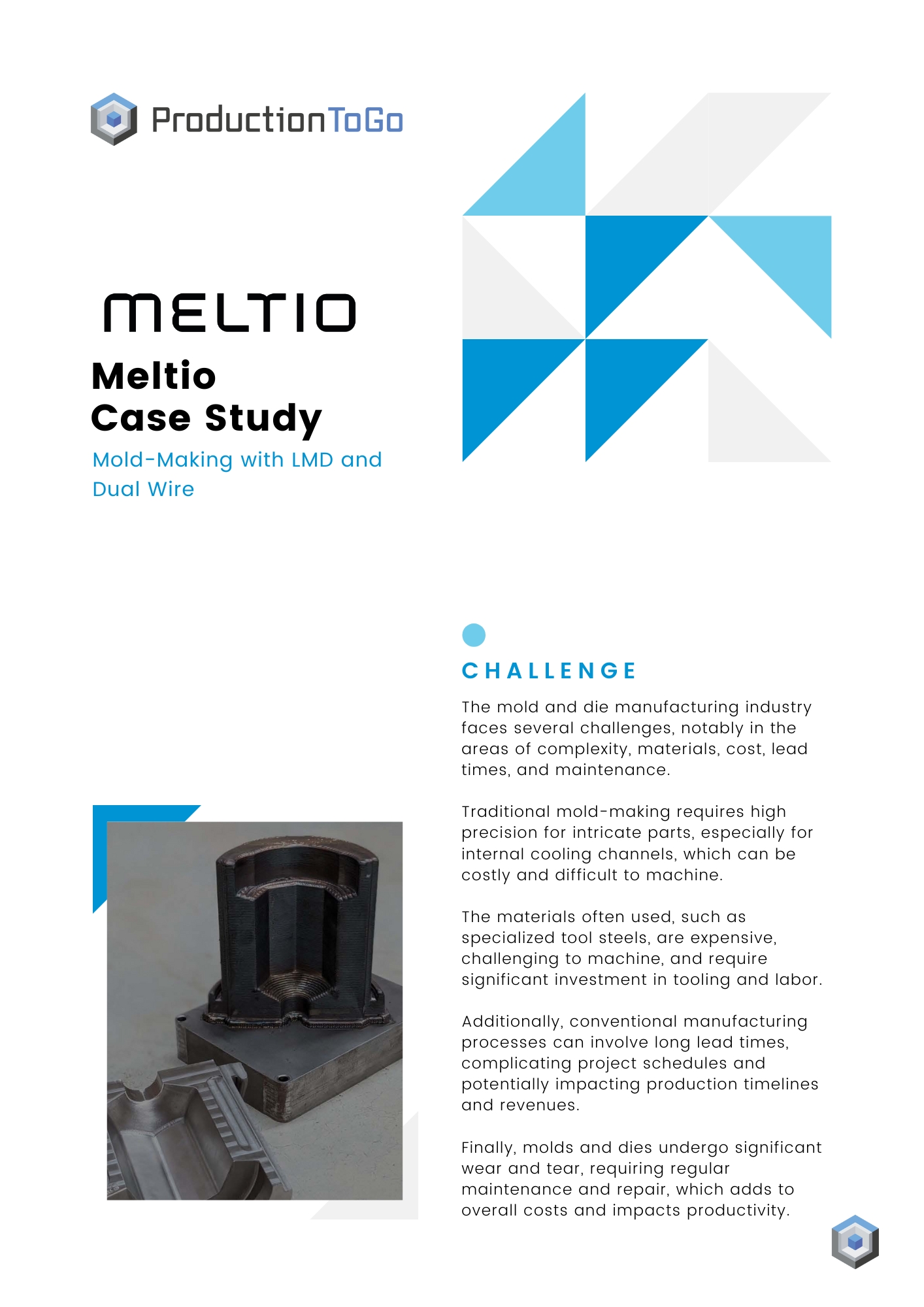

The die and mold industry faces several challenges, particularly in the areas of complexity, materials, costs, lead times and maintenance. Traditional mold making requires high precision for complicated parts, especially with internal cooling channels, which can be costly and difficult to machine. The commonly used materials, such as special tool steels, are expensive, difficult to machine and require significant investment in tools and labor. Furthermore, conventional manufacturing processes can involve long lead times, making project planning more difficult and potentially impacting production deadlines and revenues. Find out how Meltio's LMD technology solves these problems and increases efficiency in this application!

Fill up the form below and we will send you the use case by e-mail.

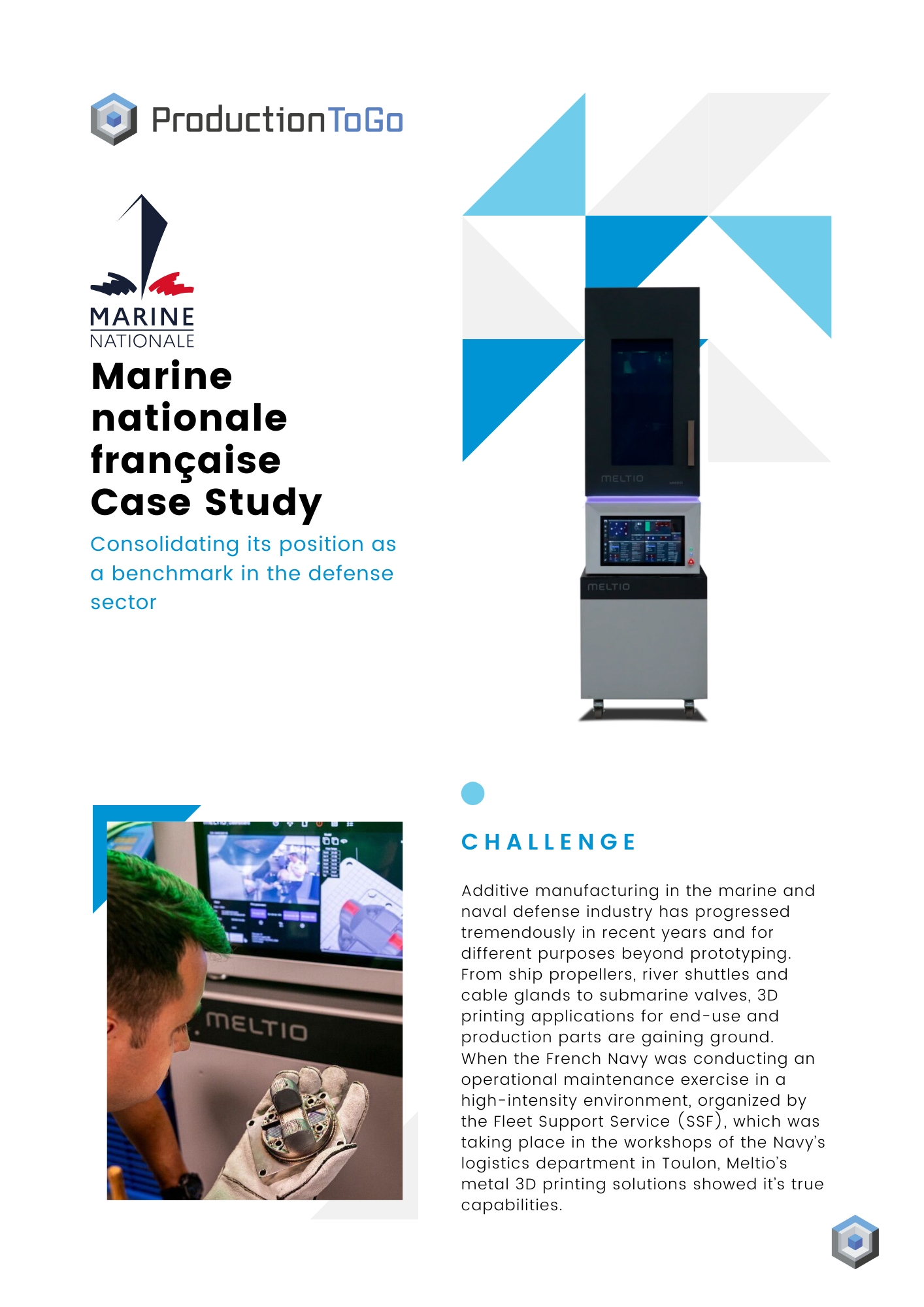

Additive manufacturing in the Navy has made tremendous strides in recent years and is used for various purposes that go beyond prototyping. From ship propellers, river shuttles and cable glands to submarine valves, 3D printing applications for end-use and production parts are on the rise. When the French Navy carried out an operational maintenance exercise organized by the Fleet Support Service (SSF), Meltio's metal 3D printing solutions showed their true capabilities. Discover how the Meltio solutions were able to demonstrate these capabilities in this use case.

Fill up the form below and we will send you the use case by e-mail.

The automotive competition sector is an industry with very demanding and complex requirements. Vehicles often require customised parts that are developed for one-off prototypes or small series. These components must meet strict requirements in terms of strength, rigidity and weight and be delivered within very tight deadlines. In addition, the vehicles are often unique and have to be redesigned every season. However, conventional processes such as machining or welding are only capable of efficiently producing complex geometries to a limited extent.

Fill up the form below and we will send you the use case by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy