3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Nexa3D® NXD 200Pro is the ideal 3D printer for high-throughput dental applications. 275 x 155 x 200 mm, a record-breaking build volume of 8.5 l and patented LSPc® technology. This comprehensive 3D printer is perfect for printing grinding trays, custom impression trays, splints, dental models and more. The intuitive user interface and ease of use match the excellent speed and throughput make the Nexa3D® NXD 200Pro perfect for dental labs.

With the xWash, the manufacturer Nexa3D® offers an effective, reliable and environmentally friendly cleaning solution for photopolymer materials.

Developed to meet the build volume and process requirements of the ultra-fast Nexa3D® NXD 200Pro, the xWash process offers customers an environmentally friendly and process-safe cleaning option.

To ensure consistent dimensional accuracy and ideally cross-linked polymer structures, the Nexa3D® xCure optimizes post-polymerization of the printed components. The Nexa3D® xCure can accommodate up to three build platforms simultaneously. The combination of thermal and UV post-curing guarantees the highest component quality.

With support for three distinct wavelengths (365 nm, 385 nm, and 405 nm), the ultrafast and highly potent xCURE Desktop UV curing system provides a flexible option for all resin 3D printers.

With most parts curing in less than 10 minutes, xCURE Desktop drastically cuts cure times by up to 80%. It is housed in a tough, anodized metal casing for exceptional durability. Because of this, users may post-process components considerably more quickly, and Nexa3D's pre-planned curing operations ensure that parts will operate predictably and have uniform mechanical qualities.

Consisting of automation cell + PostProcess (washing station) + up to 3 NXD 200Pro + Kassow Robots robot arm

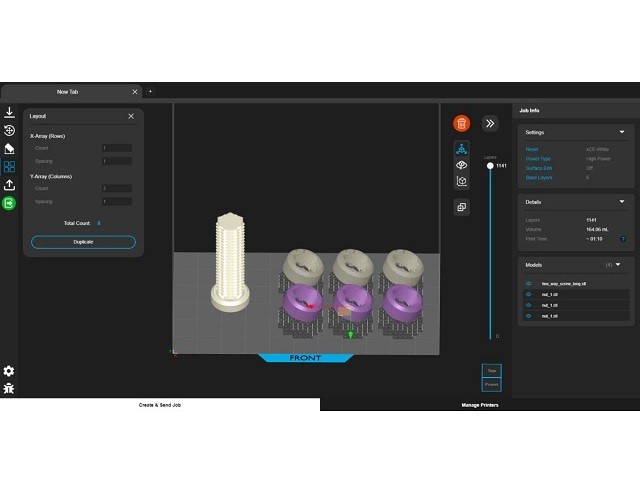

The process stability and print consistency of NexaX software make it easy to scale from prototyping to volume production.

Reduce the risk of errors throughout the 3D printing cycle, from design to manufacturing. NexaX 3D printing software provides a total solution for print preparation and printer management.

An intelligent total solution of hardware, software, and chemistry can achieve unprecedented process stability, resulting in consistent product quality.

Nexa3D's automated 3D printing decision support portal "Ximplify" assists customers in design discovery and application. In the shortest possible time, "Ximplify" generates a material recommendation and suggests the best options for implementing their project.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy