3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

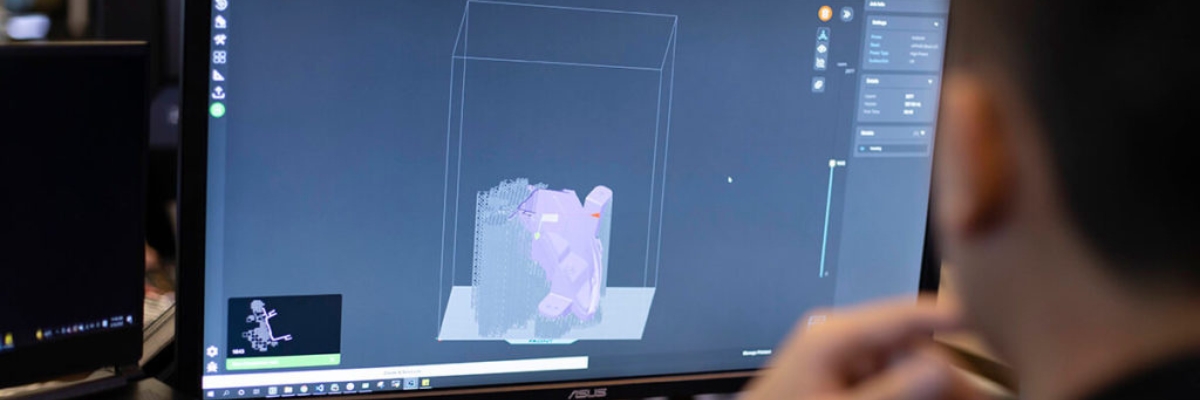

The NexaX software has numerous features that guide Nexa3D® print system users through the entire print preparation and printing process. This software optimizes and automates numerous steps to save time and reduce labor.

The Pro version of the software comes with all the basic and advanced features users need to perfect their print results.

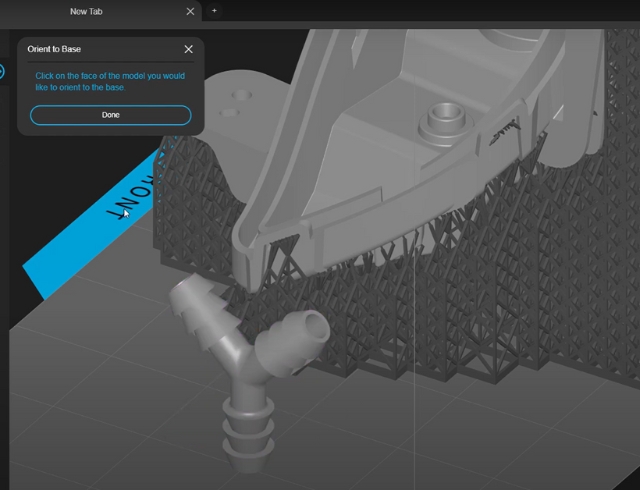

The NexaX software automates the generation of support structures and the alignment of the component on the building board. Both are optimized by algorithmic calculation to ensure printing success.

The NexaX software was designed with a special focus on a simple and intuitive user interface that allows even inexperienced users to quickly achieve results to improve their print jobs and processes.

The NexaX software provides users with a wide range of production management tools. From print history, fleet management and statistics to lists of current print jobs including durations – with the NexaX software, users can streamline their production.

The Pro version of the NexaX software makes it easy to create cavities and lattice structures, enabling the most complex components. It also allows material to be saved on large components without compromising mechanical performance.

The Pro version of the NexaX software allows the user to use resin materials from third-party suppliers such as BASF, Evonik, Henkel and many more, to obtain even more options for the mechanical, chemical, optical and physical properties of the components.

With the advanced XY-nesting of the NexaX Pro software, users can automatically optimize the space occupied by components on the build platform. This increases print reliability and throughput.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy