3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE SUMMER DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

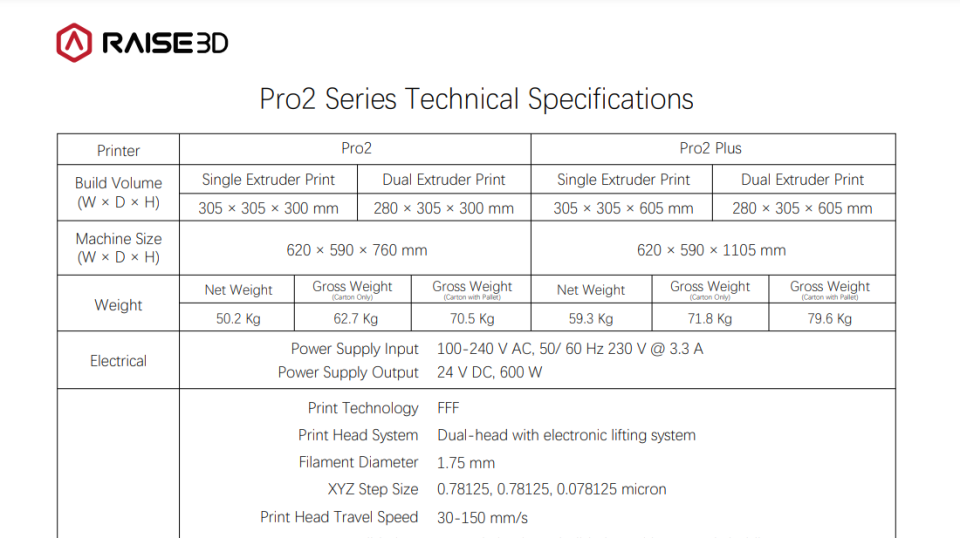

The Raise3D Pro2 is an industrial-grade 3D printer for small-batch production.

Raise3D's award-winning Pro2 series is considered the benchmark and new standard for professional 3D printing applications with 24/7 reliability. Raise3D's Pro2 Series consists of the Pro2 and Pro2 Plus, dual-extruder 3D printers with high print quality for manufacturing and rapid prototyping projects of varying sizes.

The Pro2 series is compatible with a wide range of 3D printing materials and features a metal build plate for even heat distribution. The metal frame provides optimal stability and precise positioning. The Pro2 Series is equipped with worker safety protections, a 7-inch touchscreen for efficient monitoring of the 3D printing process, and a HEPA air filter. Like all Raise3D 3D printers, the Pro2 Series can be connected to:> ideaMaker, a 3D slicing software> ideaMaker Library, a platform for sharing 3D printer files with members of the Raise3D community> RaiseCloud, a cloud-based 3D print management platform. The Pro2 Series, like all Raise3D products, is certified to both ISO 9001 and ISO 14001.

Build volume:

Raise3D Pro2 Plus: 305 x 305 x 605 mm

Raise3D Pro2: 305 x 305 x 300mm

Thanks to the dual extruder, components with different 3D printing materials and colors can be produced in a single print job. In addition, water-soluble support materials for support structures can also be printed in the second extruder.

The Pro2 Series features a unique motion system for superior part quality and precision, interchangeable 0.2-mm nozzles for more precise X/Y detail, positioning resolution of 0.78 µm on the X/Y axis, and a unique layer resolution of 0.01 mm.

The use of the ARM Cortex M7 motion controller with 400 MHz and 32-bit RISC FPU as well as a stand-alone motor controller results in precise control with maximum reliability.

The build plate is a heated, flat metal plate on which all projects are printed. An evenly heated surface on the build plate is critical to producing high-quality 3D-printed parts. It also ensures that printed materials are not damaged by uneven heat distribution.

The Pro2 Series features a HEPA air filter that cleans the air of all particles (including nanoparticles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and large and small workshops. The Pro2 Series HEPA air filtration operates silently and is designed to work unobtrusively in the background in any environment.

The Pro2 Series 7-inch touchscreens allow users to interact directly with the printer. It provides visual support and model selection to simplify control and monitoring of the printing process.

The Raise3D Pro2 series has a filament run-out sensor that warns when the filament is almost empty and saves the print. It also has a second-generation power failure feature that allows printing to resume from where it was previously saved in the event of a power failure.

Access - Monitor - Control. Work efficiently with ideaMaker by connecting wirelessly to your Pro2 Series printer.

The units also feature a built-in camera, high-quality optical end stops, a software-controlled active cooling fan, advanced hot ends and an enhanced calibration function.

Sometimes parts with sufficient strength can be manufactured to replace equivalent parts made of metal.

Fiber-reinforced 3D printing materials enable the production of functional, dynamic parts that can withstand the demands of continuous use.

Raise3D enables users to quickly produce specific, customized solutions for their manufacturing. It eliminates the need for molds, castings, or subcontractors and provides benefits that would be impossible to achieve with traditional manufacturing methods.

Parts for immediate use can be produced quickly and meet very specific requirements for all conceivable applications.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy