3D printers

High quality 3D printers

High-quality 3D printing solutions for demanding projects

Order Parts now!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

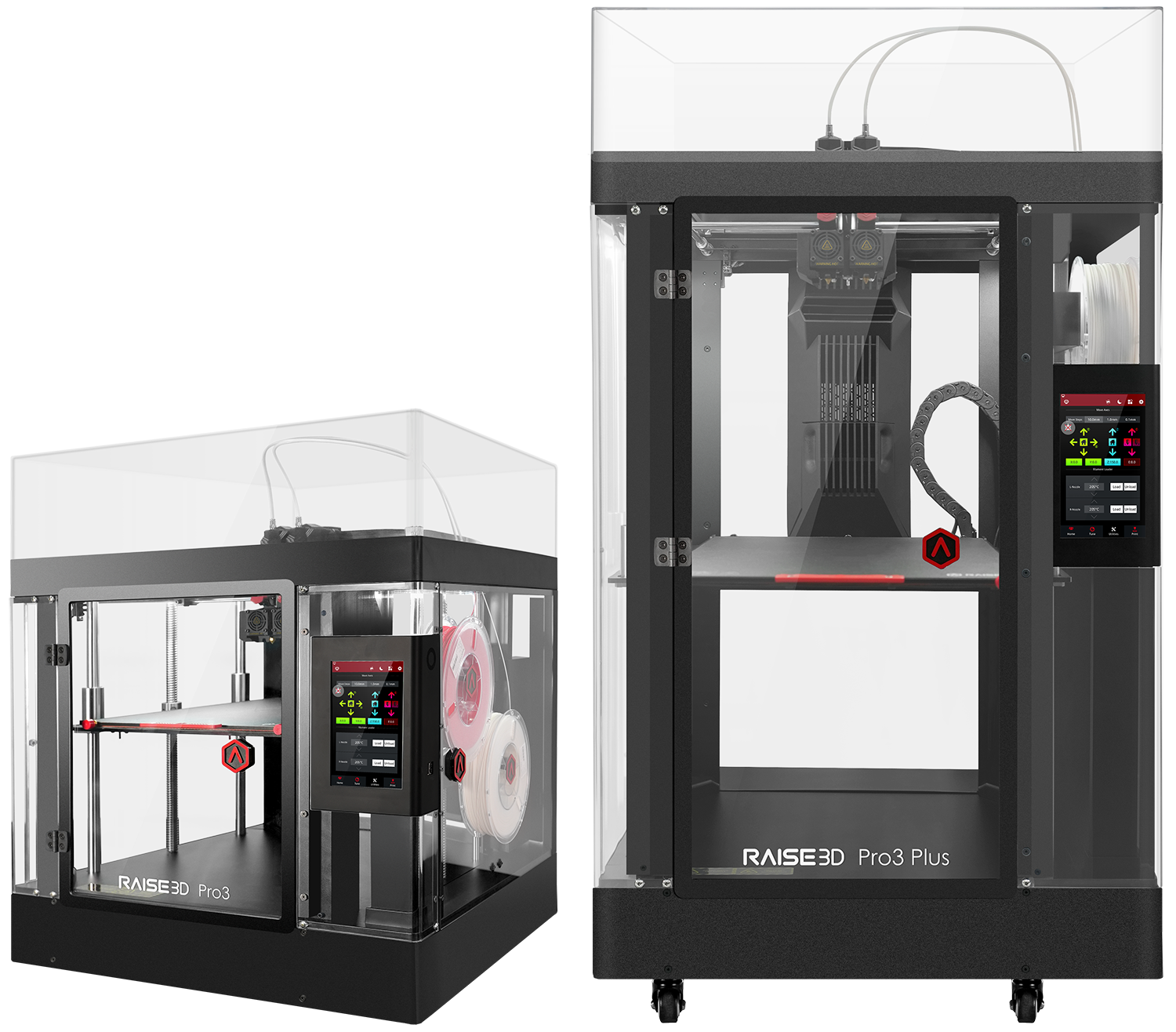

The Raise3D Pro3 series is an easy-to-use, smart and professional 3D printer.

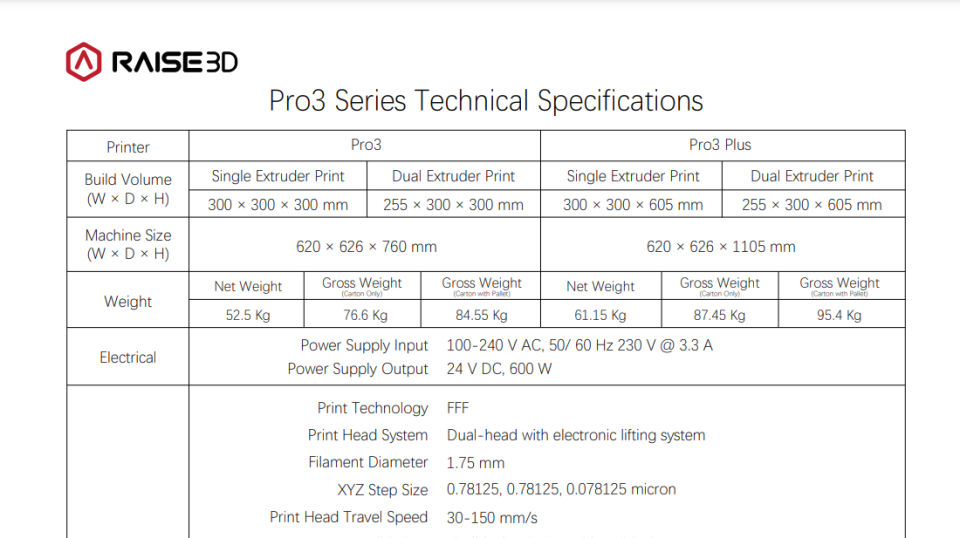

Raise3D's 2022 Pro3 Series professional 3D printers with two extruders, which evolved from the Pro2 Series, meet the needs of both production and rapid prototyping. The Pro3 series consists of the Pro3 with a build volume of 300 x 300 x 300 mm and the Pro3 Plus with a build volume of 300 x 300 x 605 mm. The dual-extruder 3D printers of the Pro3 series are an excellent choice for your professional 3D printing thanks to their high-quality printer design, advanced features and EVE intelligent assistance system.

The Pro3 series dual-extruder 3D printers are connected to Raise3D's 3D printing software ecosystem, which consists of the RaiseCloud cloud-based 3D printing platform, ideaMaker 3D slicing program and ideaMaker Library open-source template.

The Raise3D Pro3 series is equipped with an independent modular extruder with a dual extrusion system. This enables the Pro3 series to print with a wide range of filaments.

With the Raise3D Hyper Speed Upgrade Kit, you can print with the consistent print quality and increase your print speed by up to 3x. The kit comes with a Hyper Speed Auto Calibrator, two Hyper Speed 0.4mm Hot Ends, Hyper Speed PLA and ABS filaments and a software upgrade+.

The Raise3D Pro3 Series hot end is easily removable without tools, making it easy to service or replace. The front cover of the extruder is also easy to remove to locate and fix any printing problems, such as filament jams.

The Raise3D Pro3 series features an automatic leveling system for the print bed and a flexible build plate for easy removal of printed parts. The rigidity of the Z-axes has been increased by 75% compared to the Pro2 series.

The metal frame of the Pro3 series dual extruder is used for a special drive system that allows the printing system to slide smoothly during the printing process. To ensure the highest level of process accuracy, this motion system operates with precise positioning.

The Raise3D Pro3 series uses digital temperature measurement to ensure accurate temperature readings. Furthermore, the air circulation at the extruder has been improved compared to the Pro2 series.

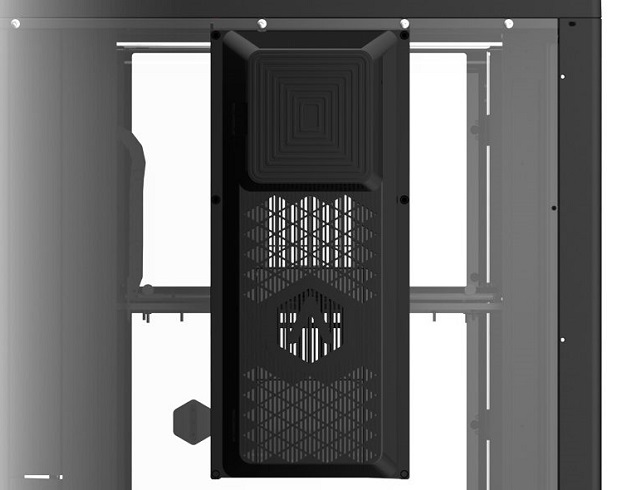

The Pro3 Series Air Flow Manager is located on the back of the printer and improves heat dissipation and air circulation, creating a stable environment in the print chamber. With a HEPA air filter, the Air Flow Manager can filter and clean the air in the chamber.

The Pro3 Series replaces the drag chain with a lightweight cable to reduce extruder weight and keep the center of gravity in the middle during printing, resulting in more stable print quality.

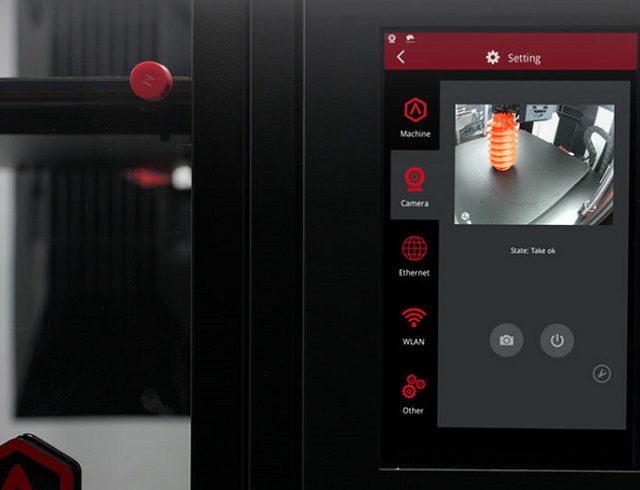

Pro3 Series users can interact directly with the printer thanks to the 7-inch touchscreen. In addition, this provides on-screen help and visual model options that make it easier to operate and manage the 3D printer and the 3D printing process.

The Pro3 Series has a built-in EVE Assistant system that provides a list of common printing problems and how to fix them. The EVE Assistant can help the user accurately identify and fix problems that could affect the print job. To ensure that printer maintenance is performed in a timely manner, the EVE Wizard provides a feature that reminds the user of regularly scheduled interventions. A more effective maintenance approach also helps reduce maintenance time and costs incurred.

Each Pro3 Series print job is monitored by an HD camera throughout the print process. This camera is connected to RaiseCloud and allows the user to monitor each print job remotely and on the go. Being able to monitor the 3D printing process gives the user peace of mind. The Pro3 series also features a newer CMOS sensor that ensures higher image quality.

The Pro3 Series extruders feature a filament run-out sensor that warns when the filament is nearly empty and saves the print operation. It also has a second-generation power failure feature that allows printing to resume from the previously saved location in the event of a power failure.

The Pro3 series has a safety function that automatically detects when a door is opened and then stops printing.

Sometimes parts with sufficient strength can be manufactured to replace equivalent parts made of metal.

Fiber-reinforced 3D printing materials enable the production of functional, dynamic parts that can withstand the demands of continuous use.

Raise3D enables users to quickly produce specific, customized solutions for their manufacturing. It eliminates the need for molds, castings, or subcontractors and provides benefits that would be impossible to achieve with traditional manufacturing methods.

Parts for immediate use can be produced quickly and meet very specific requirements for all conceivable applications.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy