3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

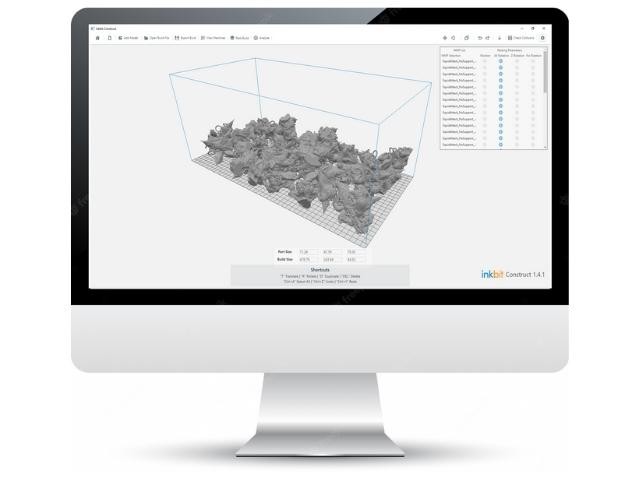

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Inkbit Vista™ printing system is designed for mass production of 3D printed parts for use in manufacturing applications. It utilizes Vision-Controlled Jetting (VCJ) technology, which provides high-resolution part quality and allows users to produce parts with precision and dimensional accuracy in high volumes.

The Inkbit Vista™ printing system comes with a material cart that features an on-demand wax melter and up to three 80-liter material tanks.

The convection furnace is used in the first step of post-processing for melting the support material from wax. Depending on the size of the print job, this step can take approximately 2 to 15 hours.

The ultrasonic cleaner is used in the second step of post-processing for dewaxing. A dewaxing liquid is used in this step. The process takes approx. 60 minutes.

In the final step of the finishing process, a hydrothermal cleaning system is used for the final cleaning of the components. This step takes about 10 minutes.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy