3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

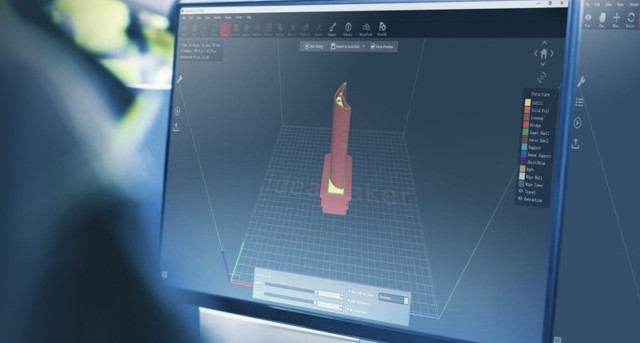

The Forge1 uses FFF technology to produce high-density metal parts for direct use after debinding and sintering. The printer has an optimized material supply system, a build platform optimized for metal filament printing and hardened nozzles.

In addition, the Forge1 offers optimized internal print parameters, process control, toolpaths and print calibration specifically designed for metal filaments.

A service in which Raise3D validates the customer's components before printing and provides the best printing parameters to successfully arrive at the appropriate metal component. This service guarantees the customer a defect-free metal part or their money back provided the Raise3D design rules are fully followed.

Thats how it works:

1. The Forge1 customer purchases a code from ProductionToGo.

2. Before printing, the customer accesses Raise3D's dedicated website and provides the necessary information (coupon code, contact information, STL file, part information...).

3. Raise3D's metal experts analyze the file and advise the customer on the best way to print the green part or if any modifications are needed.

4. In addition to the validated component and the printing parameters, the customer receives a BASF Debind & Sinter code from Raise3D.

5. The customer prints the green part using Raise3D's instructions.

6. The customer sends the printed green part and the D&S code to a BASF partner.

7. The customer receives the finished component back.

Alternatives (only in Europe):

1. The process outlined above, starting with the purchase of a code from ProductionToGo GmbH. Costs are around €180 per part.

2. Purchase of code from BASF itself to debond and sinter parts. Costs are currently around €60 per kilogram. This method does not include validation by Raise3D!

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy