3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

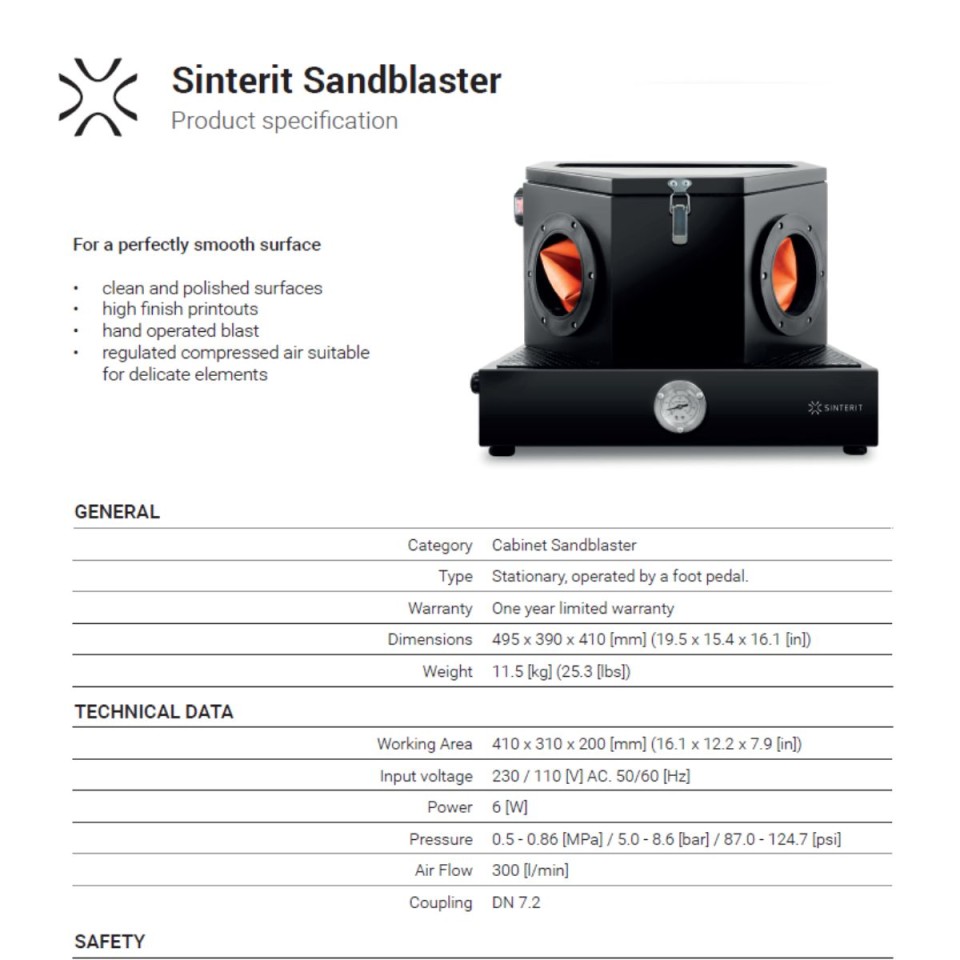

The Sinterit Sandblaster is designed for cleaning, polishing, and finishing prints with dry abrasive material.

Sinterit's compact sandblaster is suitable for simple surface finishing of components manufactured by selective laser sintering.

The small machine is suitable as an entry-level unit for the post-processing of small components and fits on a workbench or desk.

To avoid damaging sensitive components, the pressure of the blaster can be continuously changed via a pressure reducer. Use of an air compressor is required separately.

Technical data:

Working area: 410 x 310 x 200mm

Max. Pressure: 125 psi

Max. Abrasive capacity: 4.5 kg

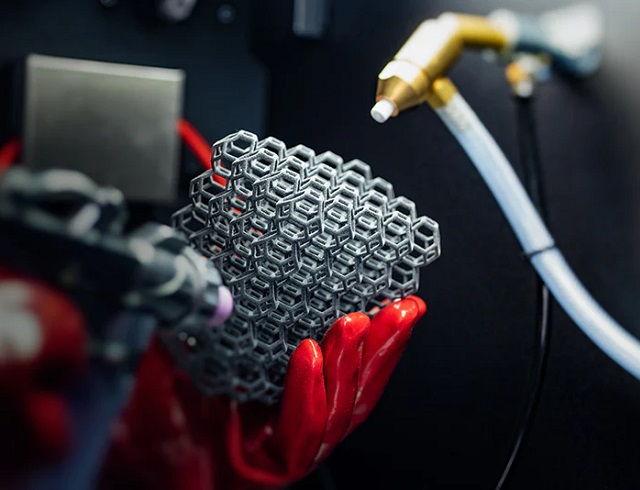

Even the smallest and most delicate prints are thoroughly cleaned thanks to the gentle pressure regulation. Precision is ensured by the additional hand-held blast gun, and free object rotation is made possible by the wall-mounted blast nozzle. The close-meshed grid prevents small parts from entering the unit and allows working with a wide range of prints.

Large working area: 410 x 310 x 200 mm. Large prints can be easily rotated and are easier to handle thanks to industrial housing. The entire system is designed to make working with SLS prints from Sinterit SLS 3D printers as convenient as possible.

The Sinterit Sandblaster is kept in a dust-free environment thanks to HEPA filtration and full sealing so that finishing is also possible without contact with the powder. The Sinterit ATEX vacuum cleaner is compatible with the Sinterit Sandblaster. The innovative mechanism of the Sandblaster separates the abrasive and the powder, and at the same time removes the particles from the chamber through a special vacuum atmosphere.

With the help of the built-in pressure gauge, you can accurately configure all working parameters. It is crucial to maintain the right pressure, especially when finishing elements with tiny details.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy