3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

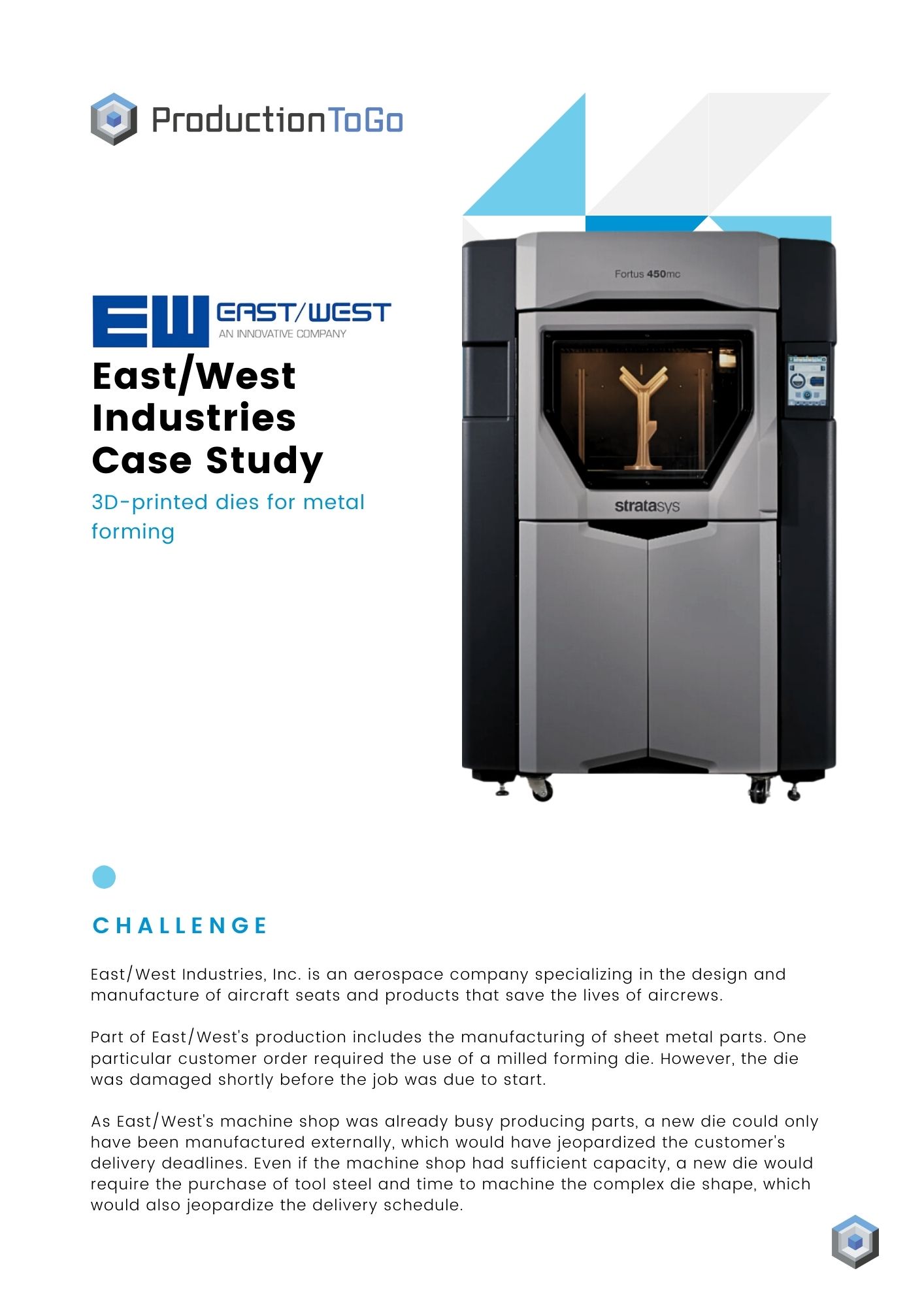

Part of East/West's production includes the manufacturing of sheet metal parts. One particular customer order required the use of a milled forming die. However, the die was damaged shortly before the job was due to start. As East/West's machine shop was already busy producing parts, a new die could only have been manufactured externally, which would have jeopardized the customer's delivery deadlines. Even if the machine shop had sufficient capacity, a new die would require the purchase of tool steel and time to machine the complex die shape, which would also jeopardize the delivery schedule.

Fill up the form below and we will send you the use case by e-mail.

The technology company Continental AG, known as one of the world's leading tire manufacturers, has a broad portfolio of solutions, including automotive parts, automated driving and mobility services. The company's global brand also includes the production of components, prototypes and small series parts for external customers. By building a center of excellence for Additive Design and Manufacturing (ADaM), Continental wanted to further strengthen its service offering and manufacturing capabilities.

Fill up the form below and we will send you the use case by e-mail.

Dr. Ulrich Koops, Product Category Manager at ProductionToGo, fulfilled his dream of owning his own sailing boat with the Dufour 2800, which was built in 1981. After more than 40 years since the keel was laid, there was a lot of work to be done, but that was precisely what appealed to him. While other parts were already hard to come by, pulleys for the sheets were the biggest problem, as they were not available individually. Instead, Dr. Koops would have had to buy a complete deflection block containing five of these rollers for €119.50 per deflection block.

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy