3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Kinetic Vision, a large product development consulting firm based in Cincinnati, Ohio, works with a large range of clients, from small startups to Fortune 500 companies, to develop new products. Their client AeroFlexx, an Innventure Portfolio Company, worked to develop an alternative to traditional liquid packaging that solves several common issues for both distributors and consumers. The packaging features flexible walls with a unique inner air-rib system to provide structure. However, the innovative concept was difficult to prototype accurately.

Fill up the form below and we will send you the use case by e-mail.

Priority Designs is an industrial design consultancy based in Columbus, Ohio. The team works with clients to help build “pretty much anything they need,” as prototype specialist Billy Rupe puts it. The company sees product design as a form of problem solving, and its role is to find solutions for customers. “Sometimes you can get buried in a CAD model,” said Senior Industrial Designer Ryan Berger. “With CAD, you have ability to infinitely zoom in and pan out, and you lose a sense of scale. You can lose the sense that you’re designing something that’s meant to be held in the hand.”

Fill up the form below and we will send you the use case by e-mail.

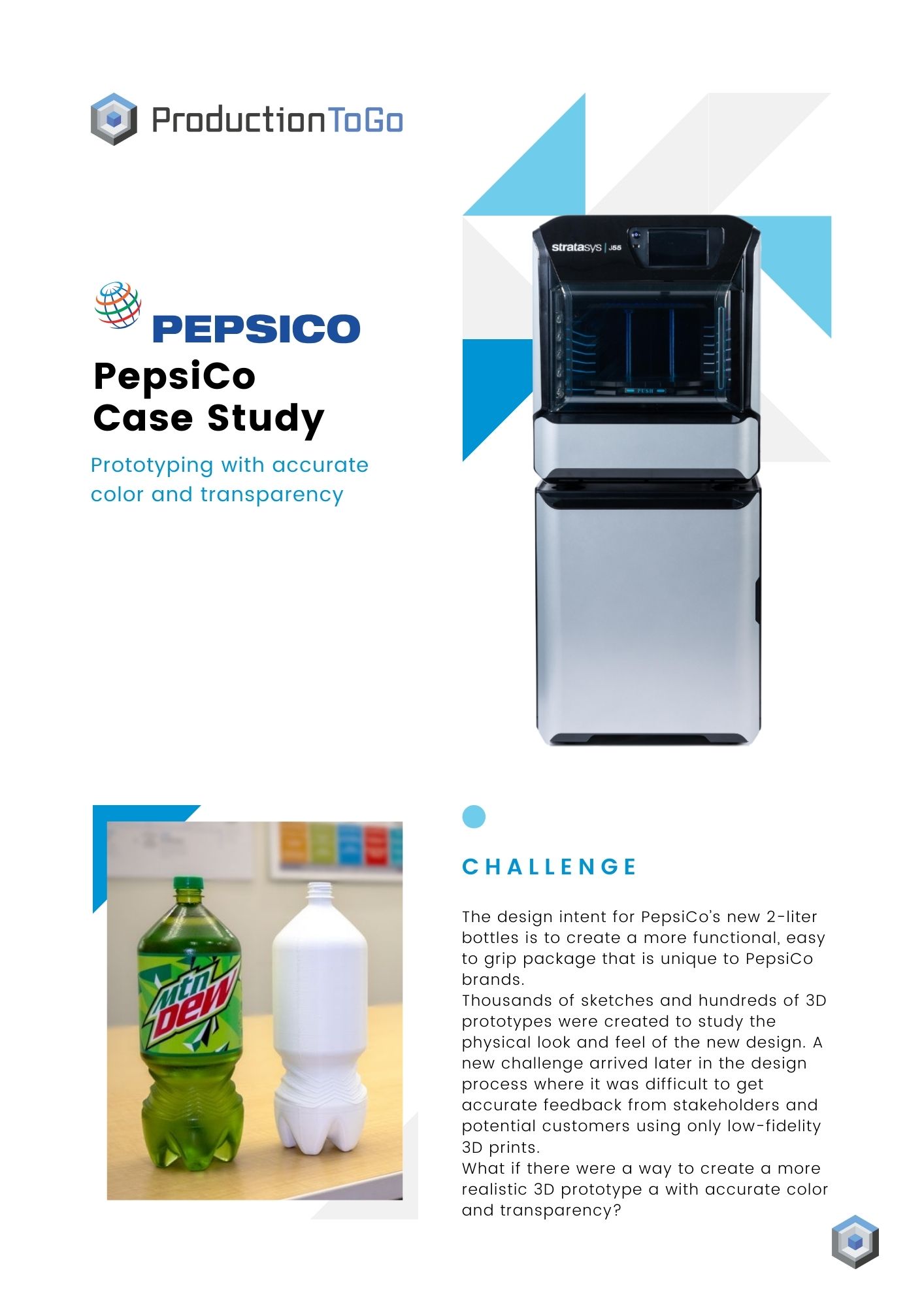

The design intent for PepsiCo’s new 2-liter bottles is to create a more functional, easy to grip package that is unique to PepsiCo brands. Thousands of sketches and hundreds of 3D prototypes were created to study the physical look and feel of the new design. A new challenge arrived later in the design process where it was difficult to get accurate feedback from stakeholders and potential customers using only low-fidelity 3D prints. What if there were a way to create a more realistic 3D prototype a with accurate color and transparency?

Fill up the form below and we will send you the use case by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy