3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Many companies across a wide range of industries are using 3D printing for their production. From aerospace to consumer goods, parts made by a 3D printer are now omnipresent.

But at least the same amount of companies would be interested in 3D printing for their production, but have difficulty deciding on the right professional 3D printer.

The technology of 3D printing can seem opaque and labyrinthine. Technical terms thrown around as if they were conjunctions and different printing processes for which mostly only acronyms are used make it difficult to choose the right professional 3D printer for one's own requirements and needs.

However, it's not just the technical side that complicates this decision. A 3D printer is a major purchase for most companies. Such a major purchase requires many questions to be answered before the acquisition.

What is the objective behind the purchase of a 3D printer? What type of 3D printer is the best way to achieve this objective? What are the costs of this investment? When can I expect a return on investment?

Many of the answers to these questions are, of course, very individual. Nevertheless, I would like to try in this blog to provide at least some impetus and rudimentary answers to simplify the decision-making process for a professional 3D printer.

A 3D printer can facilitate, improve or enable many processes in a company. A reduction in production costs, an increase in production speed or the ability to manufacture customized products are just some of the goals that can be achieved through 3D printing technology.

These goals are by no means mutually exclusive. In order to facilitate the decision for the suitable professional 3D printer, one should nevertheless set a main goal, which the investment in a 3D printer should fulfill. This main goal must of course be in direct correlation with the company's goals and the industry.

Since the multitude of different professional 3D printers, printing technologies and manufacturers offer different advantages and disadvantages, the circle of potential printers can be greatly narrowed down by setting the main target thoughtfully and correctly.

For example, if the main goal is to increase quality, it doesn't make sense to invest in a 3D printer that offers terrific speed but mediocre print quality. On the other hand, if the main goal is to produce customized products, a 3D printer that has maximum print customization capabilities is preferable to a 3D printer that offers better quality but little customization capability.

But which printers offer which advantages? Listing every single manufacturer and every single printer of these would go beyond the scope of this blog. Therefore, I would rather discuss the advantages and disadvantages of the 4 different printing technologies.

The classic among 3D printers is 3D printing with filaments. This process, called either Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM), is known nowadays primarily for its user-friendliness and affordability, both in terms of the printers themselves and the materials. Another advantage is the short post-processing time in contrast to other 3D printing processes.

However, in terms of quality, filament 3D printing has been surpassed by other printing methods. Whether it’s surface finish, level of detail or design freedom, 3D printing with filaments lags behind other printing methods.

Nevertheless, 3D printing with filaments has found its place in the industry as a cheap way to produce simple and decent quality parts. This can make it the right solution especially for companies that have cost savings as their main goal, or for companies that want to test the benefits of 3D printing for themselves over a longer period of time.

Next up is metal 3D printing. This printing process has two major subcategories, namely laser-based (e.g. Selective Laser Melting) and sinter-based printing (e.g. Metal Binder Jetting). Since the exact explanation and differentiation of these two subcategories would once again go beyond the scope of this blog, we’ll focus on the general advantages and disadvantages of metal 3D printing.

Metal 3D printing is characterized first and foremost by its unlimited design freedom. High complexity and uniqueness are no problem for this type of 3D printing. Furthermore, the high level of detail of the print jobs stands out in this printing process.

The biggest disadvantage of this printing technology is the high printer costs. These are by far the highest and in addition there may be necessary post-processing equipment. The user-friendliness of metal 3D printing systems is also not particularly high, especially due to the sometimes very complex post-processing.

Due to its high level of detail and unlimited design freedom, metal 3D printing is perfect for very complex or customized printed parts. However, due to its high cost and low user-friendliness, this printing process is more suitable for companies that have already gained experience with 3D printing or have personnel who can handle these machines.

Resin 3D printing works with liquid synthetic resin, which hardens layer by layer under the use of UV light. There are now several different printing processes within resin 3D printing, from stereolithography (SLA) to Nexa3D®'s own Lubricant Sublayer Photo-curing (LSPc®).

This type of 3D printing process stands out above all for its exorbitant surface quality and its high printing speed. The ability to produce transparent components is also a major advantage of resin 3D printing.

However, the post-processing effort is very high. On the one hand, the excess resin must be completely removed from the component, and on the other hand, the manufactured parts must be post-cured in addition to printing. Support structures are also always necessary, which have to be removed at the end of printing. In addition, both the printer costs and the material costs are relatively high.

These advantages and disadvantages make resin 3D printing particularly suitable for companies that require maximum surface quality and high speed and are prepared to spend some capital on this, or for companies that absolutely require transparent components. Resin 3D printing is particularly popular in the dental sector.

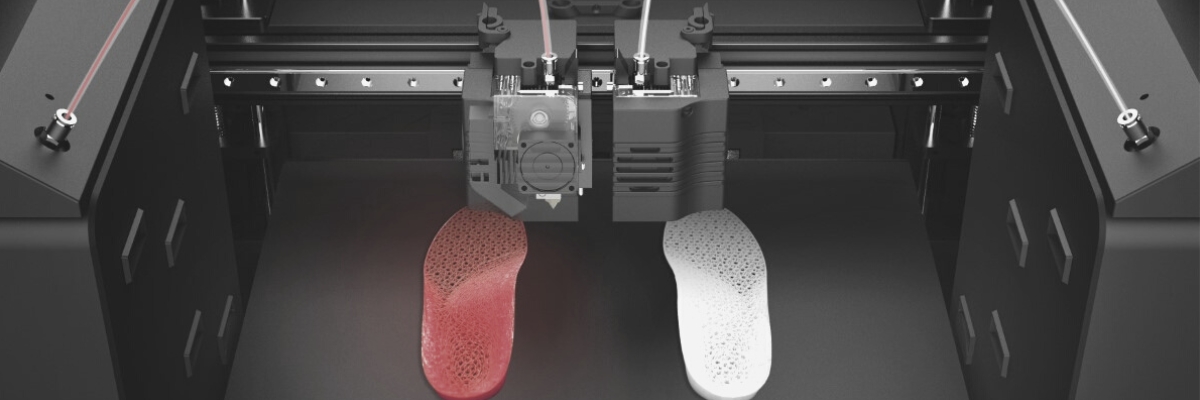

Last but not least, there is 3D printing with polymer powder. This printing process consists of Selective Laser Sintering (SLS) and Binder Jetting (BJ).

Polymer Powder 3D printing offers high quality with very good detail and parts with high strength and heat resistance. The reusability of excess powder is also a great advantage as it saves costs and has less impact on the environment.

The biggest disadvantages of this printing technology are the high printer prices and the permanent powder handling. This means that such 3D printers cannot be used in every room and protective clothing is essential when using them.

Polymer powder 3D printing is able to both increase production quality and reduce costs due to its high quality and low cumulative material costs, thanks to the reusability of the powder. However, due to the permanent powder handling, there must be a space for the 3D printer that is separate from the everyday business. This makes this type of 3D printing less suitable for very small companies.

A good setting of the main goal can always exclude at least one, if not several, printing methods. This can reduce the number of possible professional 3D printers to a more manageable level.

And now? Thinning out the printer selection is all well and good, but it doesn't make a final decision. To reach it, we need to look at the quality of the machine itself and the print jobs it produces for the printers that are still possible and evaluate the cost of acquisition.

The quality of the printer itself directly reflects the quality of the prints. But the quality of the printer also has a direct effect on the costs. If the printer is poorly installed, there will be more frequent costs for misprints, repairs and possibly a complete loss of investment if the printer is totally damaged.

Finding out about the quality of printers takes some time. Research on the Internet, reviews in trade magazines or on YouTube and visits to trade shows and showrooms offer ideal opportunities to learn more about the quality of the machines.

The best way to test the quality of the print jobs themselves is to try them out with a vendor/manufacturer. Many of these offer simple test prints free of charge. These test prints are also a great way of evaluating certain properties of the print job that are necessary for the subsequent application (e.g. heat resistance or bendability).

Furthermore, possible material restrictions of the printers must also be taken into account. Some printers have an open material system with which materials from third-party manufacturers can also be printed. Other printers on the other hand are limited to the manufacturer's own materials.

Therefore, care must also be taken to ensure that the quality of the materials that can be used meets one's own requirements. The best 3D printer in the world is of no use if the materials used are of inferior quality.

Of course, the costs must never be disregarded when making an investment. How much capital a company wants to spend is very individual. Nevertheless, there are some points that must always be considered when it comes to costs.

Everyone should be aware that a professional 3D printer costs money. Depending on the printing process, build volume, additional features (e.g. automation options) and much more, the cost of a professional 3D printer can vary greatly.

However, the ancillary costs must also always be considered in such an acquisition. Electricity costs, material costs, commissioning costs, personnel costs, possibly necessary accessories and more must all be included in the cost calculation.

The after-sales service offered by the seller/manufacturer should also be taken into account, both in terms of its content and its cost. A good after-sales service can facilitate many things around the purchase of the 3D printer. Whether it is the installation of the printer, training in the use of the printer, a repair service or permanently available hotlines, the after-sales service can aid in every life cycle of the product.

The most important key performance indicator for such a large purchase is always the return on investment. When the ROI can be achieved is very individual and depends on the printing process, utilization, production speed, demand, and a few other points.

Generally speaking, 3D printing can save up to 70 % of production costs! How high this percentage is in individual cases depends heavily on the frequency of use. The more the 3D printer is used, the faster the return on investment is achieved.

Depending on the objectives and budget, quality and costs must be compared. It does not always have to be the most expensive or best model to meet certain objectives of a company!

The most important questions to ask and answer before purchasing a 3D printer are:

- What is my main goal in making the purchase?

- Which printing processes are suitable for my goal and possibilities?

- What quality do I expect?

- Which machine and which test print convinced me the most?

- How much capital am I willing to spend on the printer?

- Have I paid attention to the ancillary costs?

Should you be able to answer all these questions with ease, you are almost certainly ready to take the step to a professional 3D printer and with it the step into the future!

3D printing is a promising technology that is already serving many companies to achieve their goals better and faster and will serve many more companies in the future.

If you would like to learn more about the process and issues surrounding the purchase of a professional 3D printer, you can register for a webinar* on this very topic here!

*The Webinar will be held in german

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy