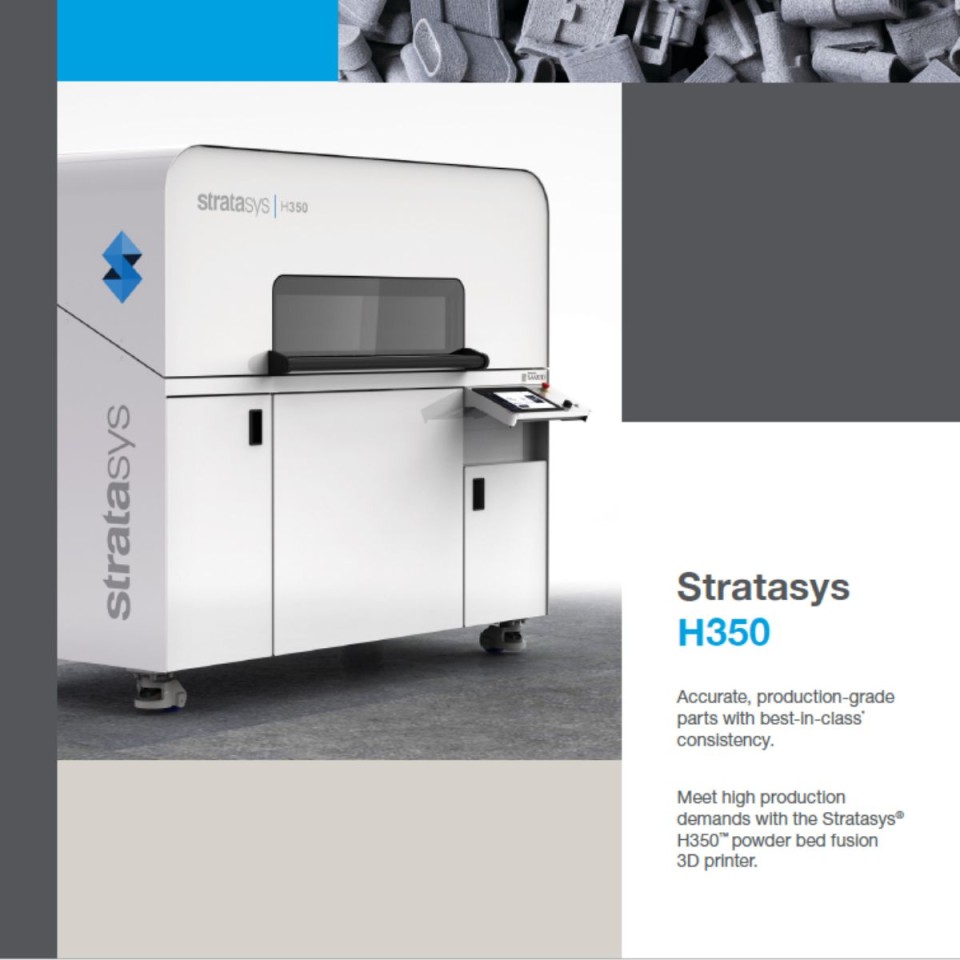

3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

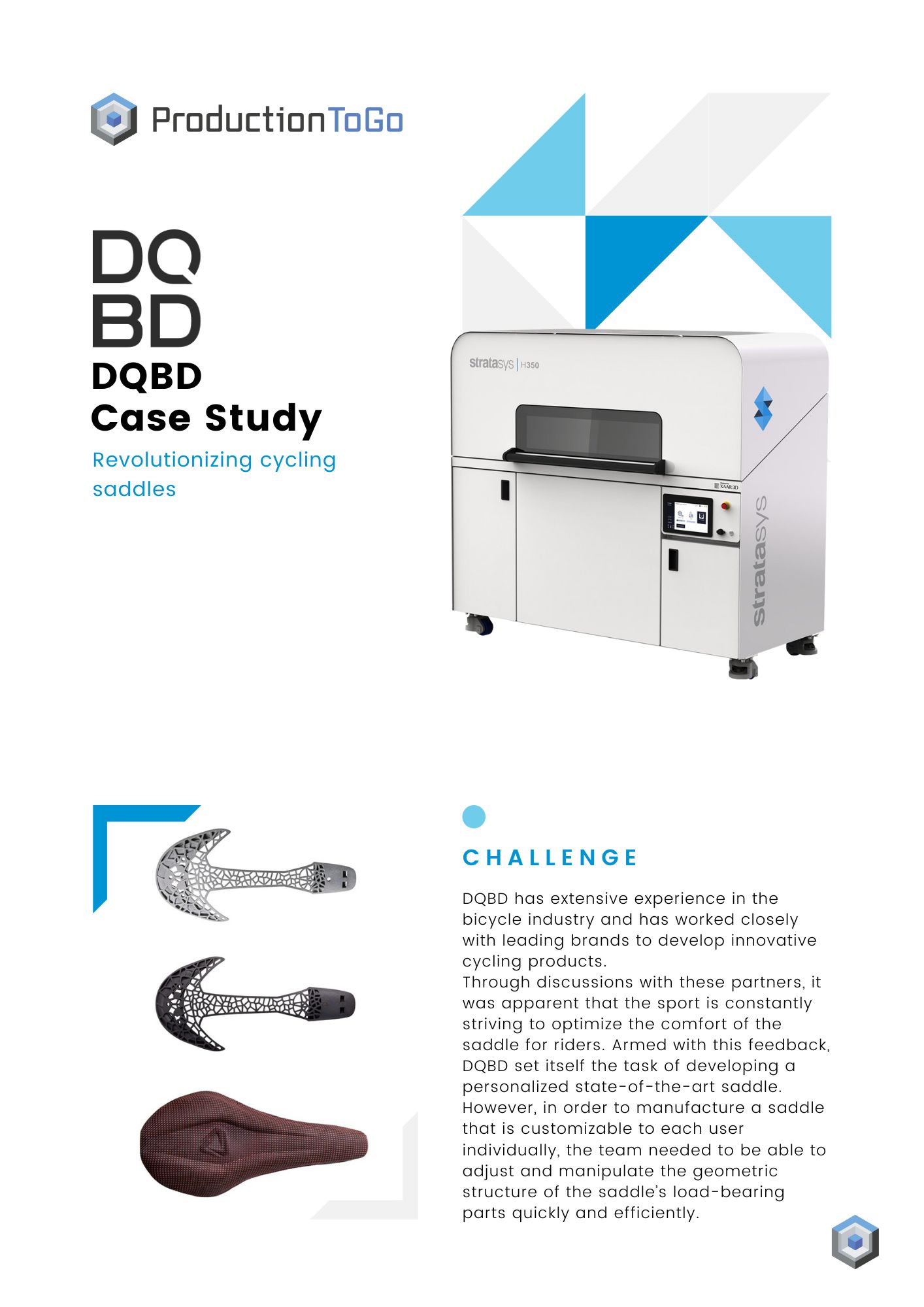

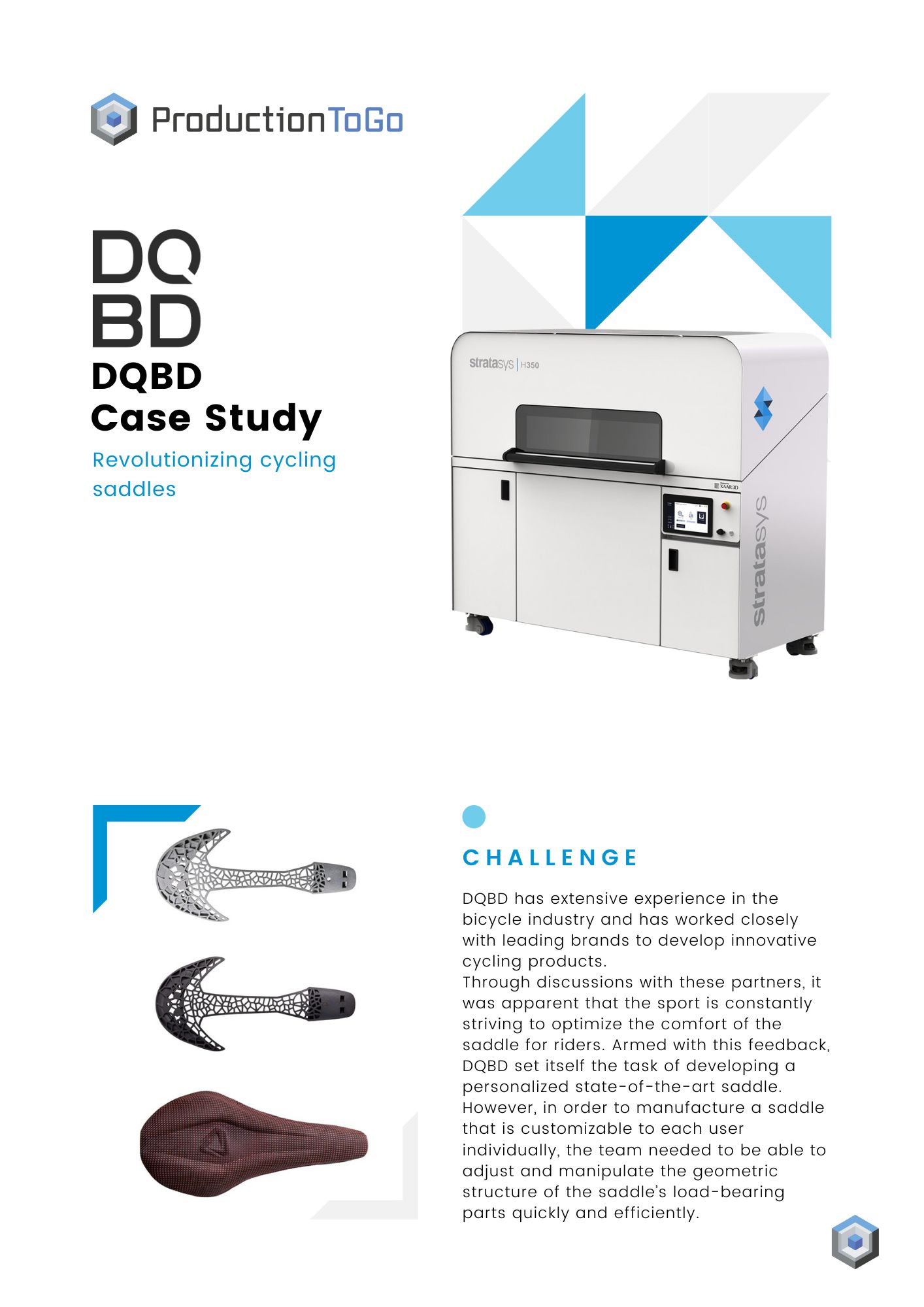

DQBD has extensive experience in the bicycle industry and has worked closely with leading brands to develop innovative cycling products. Through discussions with these partners, it was apparent that the sport is constantly striving to optimize the comfort of the saddle for riders. Armed with this feedback, DQBD set itself the task of developing a personalized state-of-the-art saddle. However, in order to manufacture a saddle that is customizable to each user individually, the team needed to be able to adjust and manipulate the geometric structure of the saddle’s load-bearing parts quickly and efficiently.

Fill up the form below and we will send you the use case by e-mail.

Serving clients in the medical and traditional manufacturing markets, Götz Maschinenbau is a Germany-based mechanical engineering company. While traditional manufacturing methods such as turning, welding, molding and milling have been a staple part of Goetz over the years, 3D printing also plays a central role for the company across design and manufacturing. However, when it comes to producing volumes, Götz has been reliant upon traditional manufacturing methods. While part quality is great, this has come at a cost to the business with mold production extremely costly and time-intensive.

Fill up the form below and we will send you the use case by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy