3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

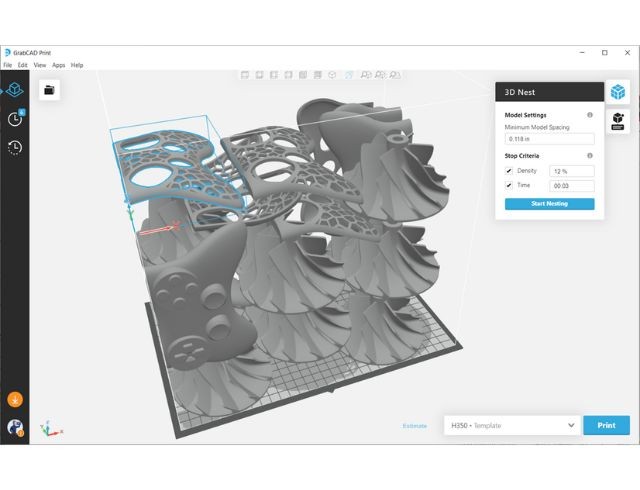

The H350™ printer outperforms rival powder bed devices by utilising a number of characteristics. Your operating expenses will drop with fewer consumables, which will eventually result in a cheaper cost per part. In comparison to alternative alternatives, the higher nesting density boosts production and lowers the cost per part. Whatever the need, the H350 pushes the boundaries of additive manufacturing productivity.

The removal box is made up of a detachable bottom plate and a box. As soon as the build operation is finished, terminated, or fails, the build can be removed.

Any powder that is not contaminated during unpacking and part cleaning can be processed using the powder retrieval station and then used again. Powder recovery can be optimized for reuse in later builds if managed appropriately.

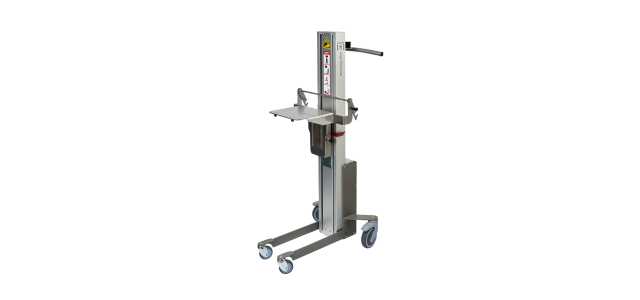

This trolley lifts the powder container using an electric motor. The powder container tilt component, a fast release bracket-mounted metal bracket, is part of the trolley. To make it easier for powder to flow from the container to the printer, the bracket can be turned 180 degrees.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy