3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

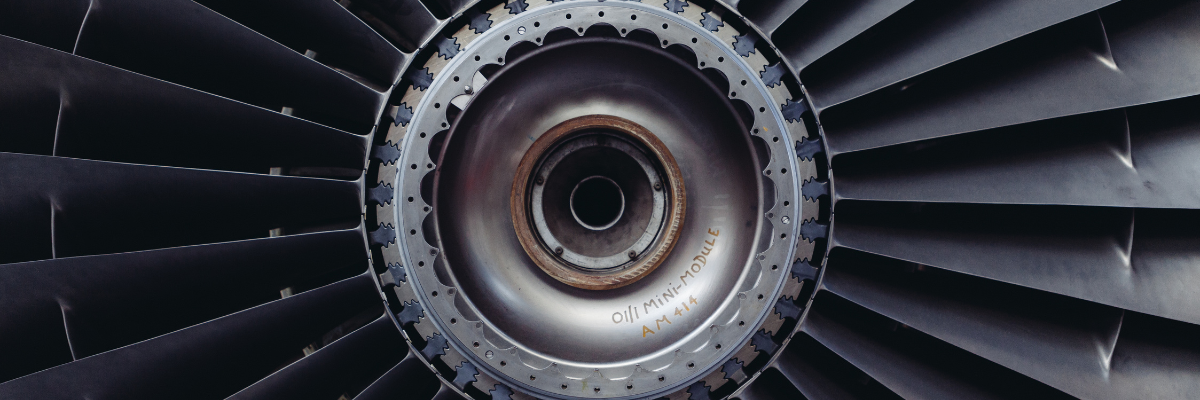

Additive manufacturing technology has made a lasting impression on the aerospace industry in recent years. 3D printing massively simplifies the production of small and complex components. Based on user-defined parameters, 3D printing allows the cost-efficient production of components.

Nowadays, it is possible to manufacture lightweight and airworthy aircraft parts from high-performance thermoplastics that have the temperature, chemical and UV resistance required for aircraft.

Engineers are now increasingly relying on Additive Manufacturing to turn their ideas into reality faster. The ability to produce models and prototypes on the spot and on demand means that tests can be carried out on components far more quickly, maximizing production efficiency. This in turn minimizes the time between idea and implementation and thus the time to release, which saves costs.

Industrial 3D printers can produce very strong and lightweight structures, which allow a weight reduction of 40 – 60 %.

This ensures leaner cost structures, material savings and lower fuel consumption.

3D printing enables the integration of components with maximum functionality in as few individual parts as possible.

This ensures lower assembly and quality assurance costs and the elimination of weak points associated with assembling many different components.

The tool-less production process enables faster implementation of necessary product adjustments, which means that errors can be eliminated more quickly and improvements can be realized faster.

This provides greater flexibility in product development.

By producing components on demand, spare parts do not have to be stored in a long-term and cost-intensive manner but can simply be produced in-house at high speed as soon as they are needed.

This ensures less storage space is required and thus saves costs.

Lighter and more efficient components such as engines and turbines can massively reduce aircraft fuel consumption.

This ensures lower CO2 emissions and thus a lower impact on the environment.

Additive Manufacturing provides cost savings in many different areas. Faster production, less required storage space, tool-less manufacturing, more flexibility and much more make 3D printing a guarantor for cost savings.

3D printing provides better quality, faster production and reduced costs in the aerospace industry.

More and more manufacturers of aircraft parts are switching to additive manufacturing. A trend that will almost certainly continue in the future!

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy