3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

In the minds of many people, the word sustainability is usually associated with higher costs - and unfortunately this is true for many materials.

When recycling classic plastic, for example plastic bottles, the different types of plastic have to be separated from each other, as despite our initiative to separate different types of waste, many different types of plastic still end up in the same garbage can. The plastic then has to be washed and finally reprocessed. This whole process is more cost-intensive than simply producing fresh plastic.

However, the situation is completely different with polymer powder in additive manufacturing. Here, reusing the material kills two birds with one stone - it is more sustainable and at the same time more cost-effective than simply producing or buying new material.

In this blog post, I will explain how exactly the recycling of polymer powder works in 3D printing, what requirements must be met for problem-free reuse and whether there are any disadvantages to this recycling.

In most cases, support structures are required for every type of additive manufacturing. These ensure that even complex components remain stable during construction and do not collapse.

These support structures must of course be removed after the print has been completed. Whether they are removed by hand, with a flush cutter, with sandpaper or, in the case of FDM/FFF, with soluble support material by washing, the support structures are almost exclusively production waste after removal.

However, 3D printing with polymer powder is different. No classic support structures are required here, as the powder layer on the build plate itself is sufficient to support the component. This powder is not sintered or bonded during the printing process and is therefore unused powder.

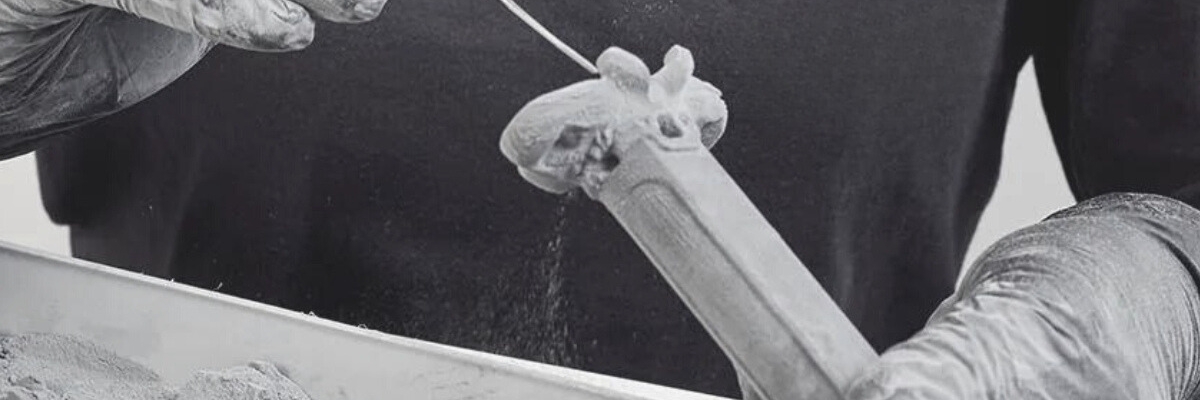

Nevertheless, this unused or excess powder must also be removed from the component. Depending on the complexity of the component and the equipment of the production plant, this can be done either by hand or by machine support such as a powder handling station.

However, this excess powder is by no means production waste; it can be fed back into the printer to print further components. Depending on the packing density and refeed rate, a complete printing process can even be completed using only previously unused powder.

The most important term relating to the reuse of polymer powder is the refresh rate. This is nothing other than the proportion of new powder in relation to recycled powder in a print job.

The refresh rate varies depending on the type of polymer powder, the duration of the heating and cooling cycles of the respective printer, the packing density and the application areas of the components. It is very difficult to give an exact average value, but in most cases it is between 20 and 50 %. However, so-called zero-waste solutions are now also possible, meaning that components can be made entirely from recycled powder.

Before polymer powder can be reused, however, it must first be processed. Although the powder is not printed, its composition is still affected by the heat or the binder, especially the regions directly around the print job. This can cause lumps to form during the printing process, which would affect the quality of a new print job.

This preparation takes place by sieving the powder. There are now a wide range of automation options for this sieving, but classic manual sieving is also sufficient to make the powder fully functional again.

The question of how often the powder has already been reused is also essential when it comes to ideal reuse. The more often powder is recycled, the higher the refresh rate and the greater the effort required for sieving. It is therefore essential to keep a close eye on how often a powder has already been reused.

The advantages of recycling polymer powder have already been touched on in this blog post. From cost minimization and a faster return on investment to the minimization of waste and the associated environmental protection to the reduction of supply risks - the advantages are diverse and manifold.

Nevertheless, some restrictions are unavoidable when recycling polymer powder. Probably the most drastic restriction is the rougher surface. Depending on the refresh rate and the number of reuses, a relatively smooth powder can result in a relatively uneven end result.

The keyword refresh rate can also lead to limitations. Although many manufacturers specify an ideal refresh rate, a certain amount of experimentation is essential to obtain the ideal components for your requirements. Experimentation is rewarded, as it allows you to adjust the ratio of new material and the resulting costs exactly to your own requirements.

However, experimentation involves a certain amount of effort. Although sieving old powder, mixing it with the new powder and maintaining the appropriate new feed rate no longer involves an enormous amount of work thanks to automation options, time is nevertheless lost.

In principle, recycled powder can be used for all applications. Provided the refresh rate is right, high-quality end-use parts can also be produced with recycled powder. However, recycled powder is perfect for prototypes and design iterations.

Functional and geometric prototypes in particular are ideal here. The possibly rougher surface is far less important for these types of prototyping than for a design prototype, for example.

However, reused powder can also be used for design iterations. This allows a large number of iterations to be produced with minimal new costs. This large number of iterations also saves costs later during final production, as the more intensive validation of the end product minimizes faulty designs or planning errors.

The term "zero-waste solution" has already been mentioned in this blog post. If these zero-waste solutions already exist, i.e. 100% of the powder can be recycled, then surely complete circular production within additive manufacturing with polymer powders is already possible, right?

The answer to this question is a cautious "yes". Materials already exist, such as Bluesint PA12 from Materialise or Windform® XT 2.0 IMG, which are made from 100% recycled powder. Printing systems, such as the QLS 260 from Nexa3D®, now also make it possible to produce high-quality components from 100% recycled powder thanks to very short heating and cooling cycles and an open material platform.

So why only a cautious yes? Well, no polymer powder in the world can be reused indefinitely. Even with short heating and cooling cycles, at some point the composition of the powder will have changed so much that it can no longer be used to produce high-quality components. So to maintain high quality, sooner or later fresh powder will have to be reintroduced into the cycle.

The variety of materials for fully recycled powder is also still far removed from the general variety of polymer powders. Certain powders can never be fully recycled due to their composition. This limits the choice and, in turn, the possible areas of application.

However, these limitations should in no way diminish the progress of zero-waste solutions. The ability to produce high quality components over a long period of time using only recycled powder is a huge step in the right direction - both in terms of production costs and environmental impact.

And progress has by no means come to an end. Countless companies and manufacturers of 3D printers and materials are constantly researching how to make the reuse of polymer powder even more productive and efficient.

If you're interested in keeping up to date with these advances, then keep checking this blog. As soon as new ground-breaking advances are made in this field, you can be sure that my fingers will already be tapping the keys to let you know!

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy