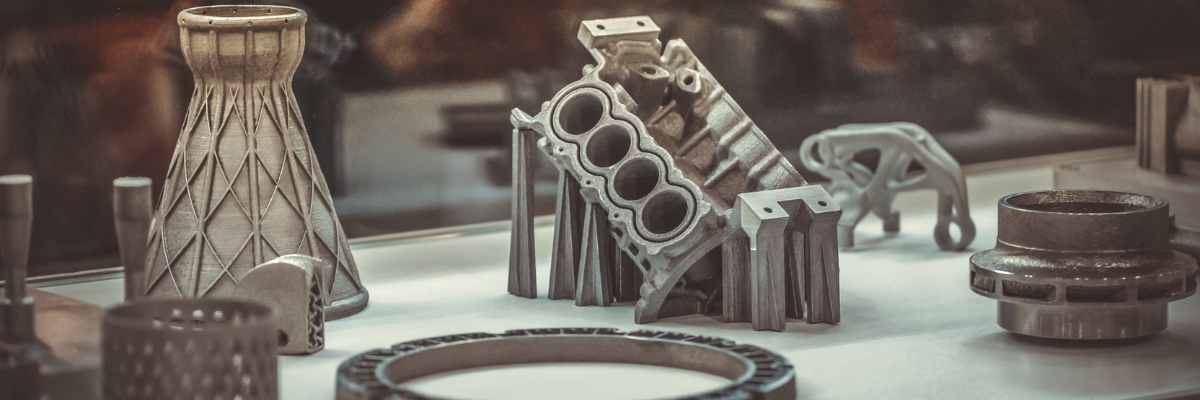

3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

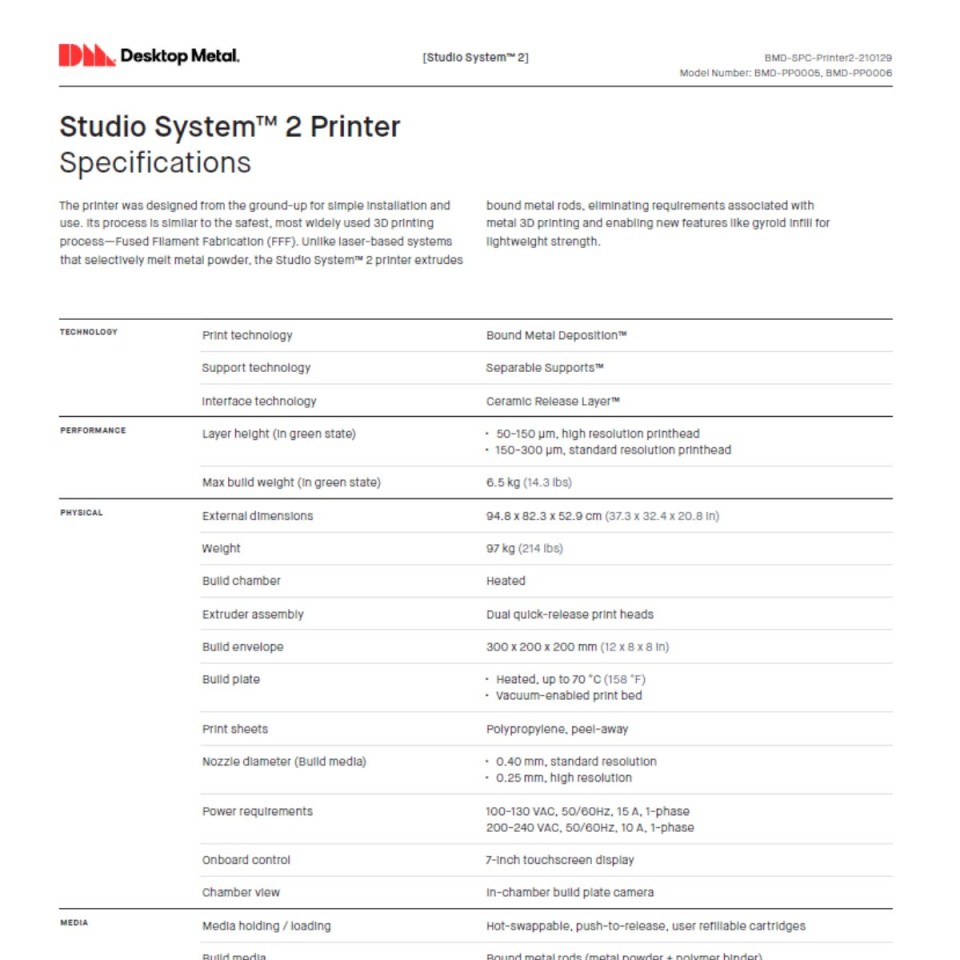

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

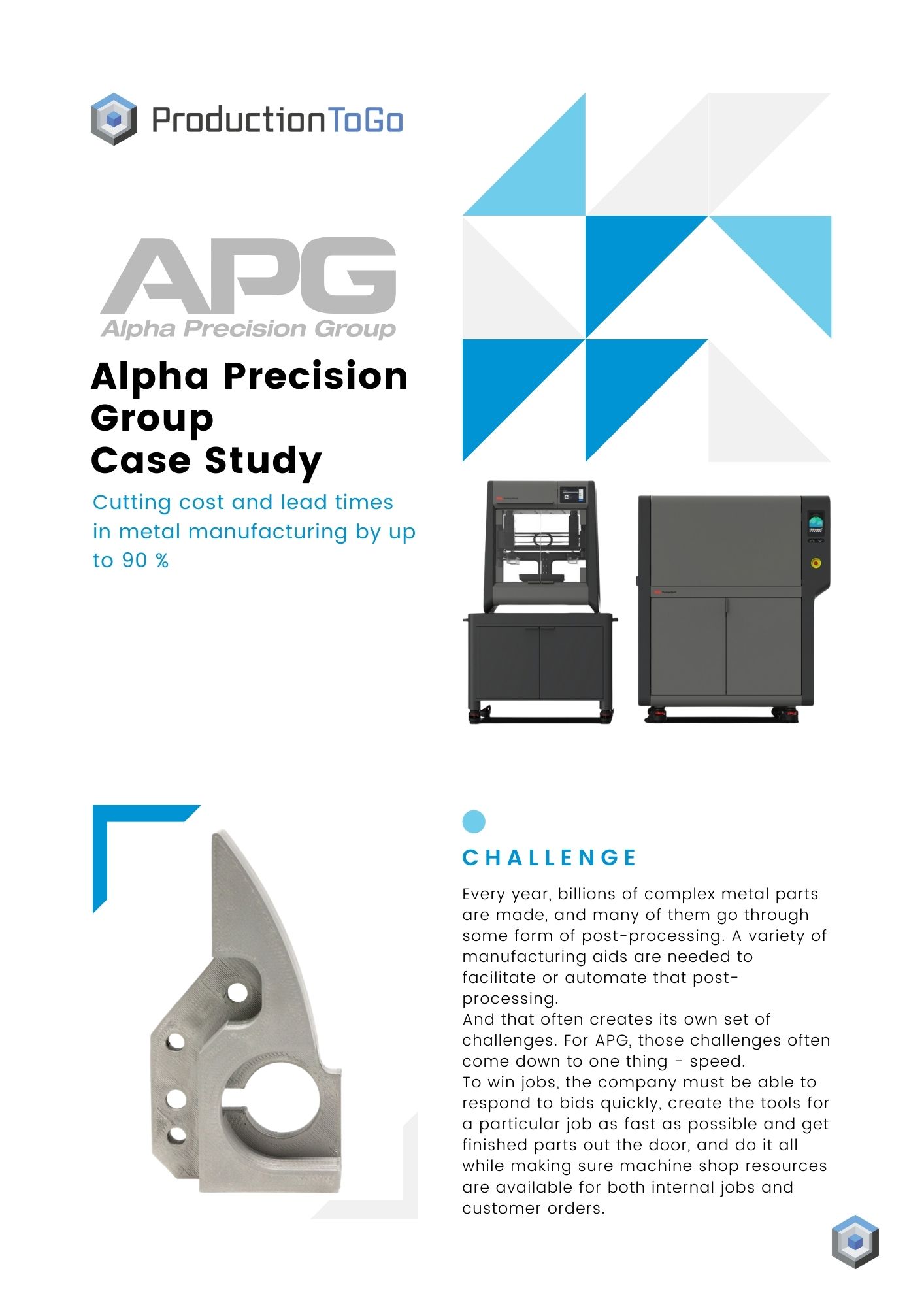

Every year, billions of complex metal parts are made, and many of them go through some form of post-processing. A variety of manufacturing aids are needed to facilitate or automate that post-processing. And that often creates its own set of challenges. For APG, those challenges often come down to one thing - speed. To win jobs, the company must be able to respond to bids quickly, create the tools for a particular job as fast as possible and get finished parts out the door, and do it all while making sure machine shop resources are available for both internal jobs and customer orders.

Fill up the form below and we will send you the use case by e-mail.

The automotive industry consists of a vast network of suppliers and vendors producing millions of parts for the thousands of assemblies and subassemblies that go into every vehicle on the road. At Egar Tool and Die, the challenges are two-fold. First, the company must be able to quickly produce dies to meet customer requirements. But as a producer of more than 15 million stamped parts and welded assemblies annually, Egar must be able to quickly retool for different jobs. To do it, the company is investing in state-of-the-art manufacturing technology, including metal 3D printing.

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy