3D printers

High quality 3D printers

HealthcareToGo Dental Innovations Tour 2025 - North Germany

Secure your seat

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

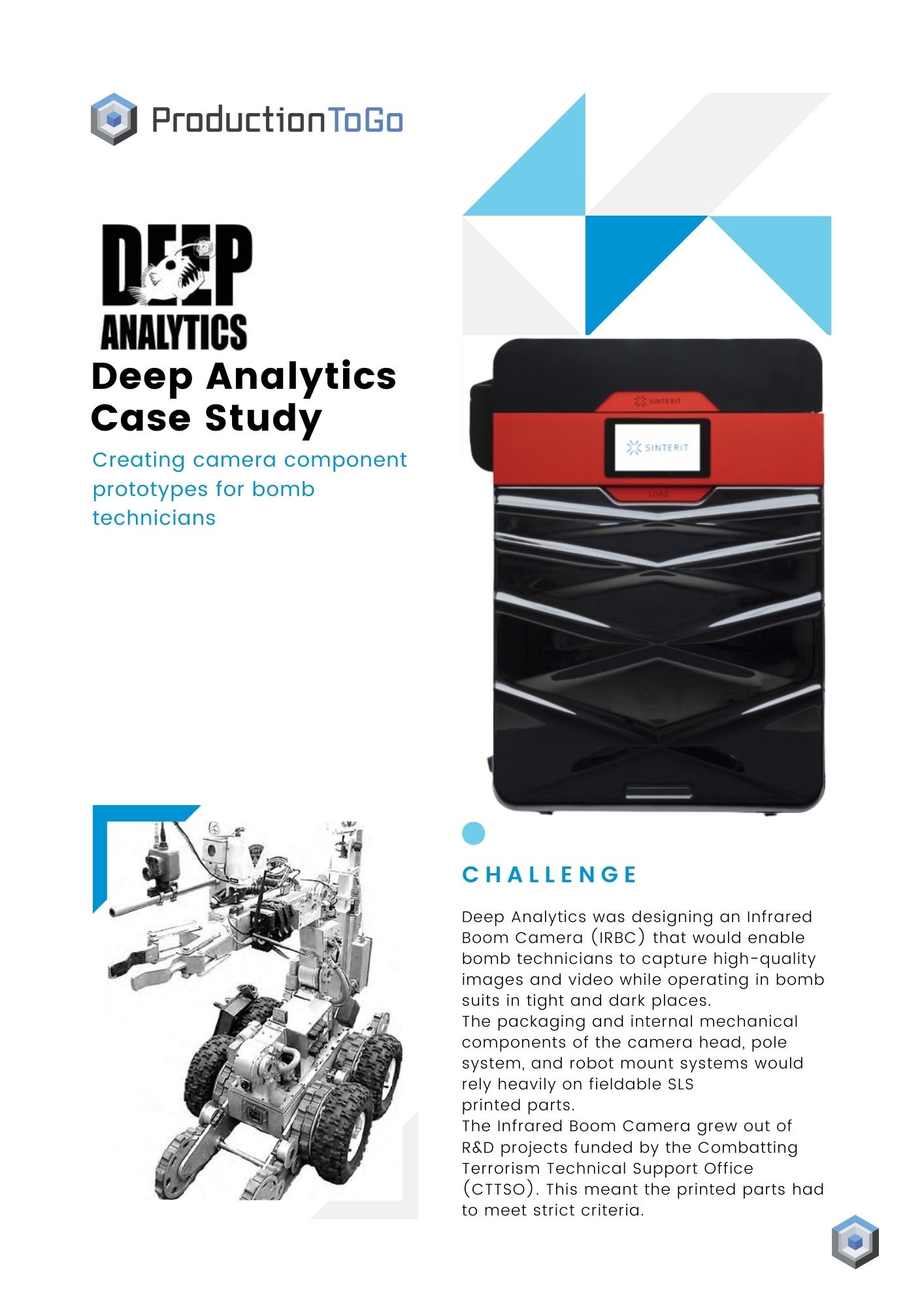

Deep Analytics was designing an Infrared Boom Camera (IRBC) that would enable bomb technicians to capture high-quality images and video while operating in bomb suits in tight and dark places. The packaging and internal mechanical components of the camera head, pole system, and robot mount systems would rely heavily on fieldable SLS printed parts. The Infrared Boom Camera grew out of R&D projects funded by the Combatting Terrorism Technical Support Office (CTTSO). This meant the printed parts had to meet strict criteria.

Fill up the form below and we will send you the use case by e-mail.

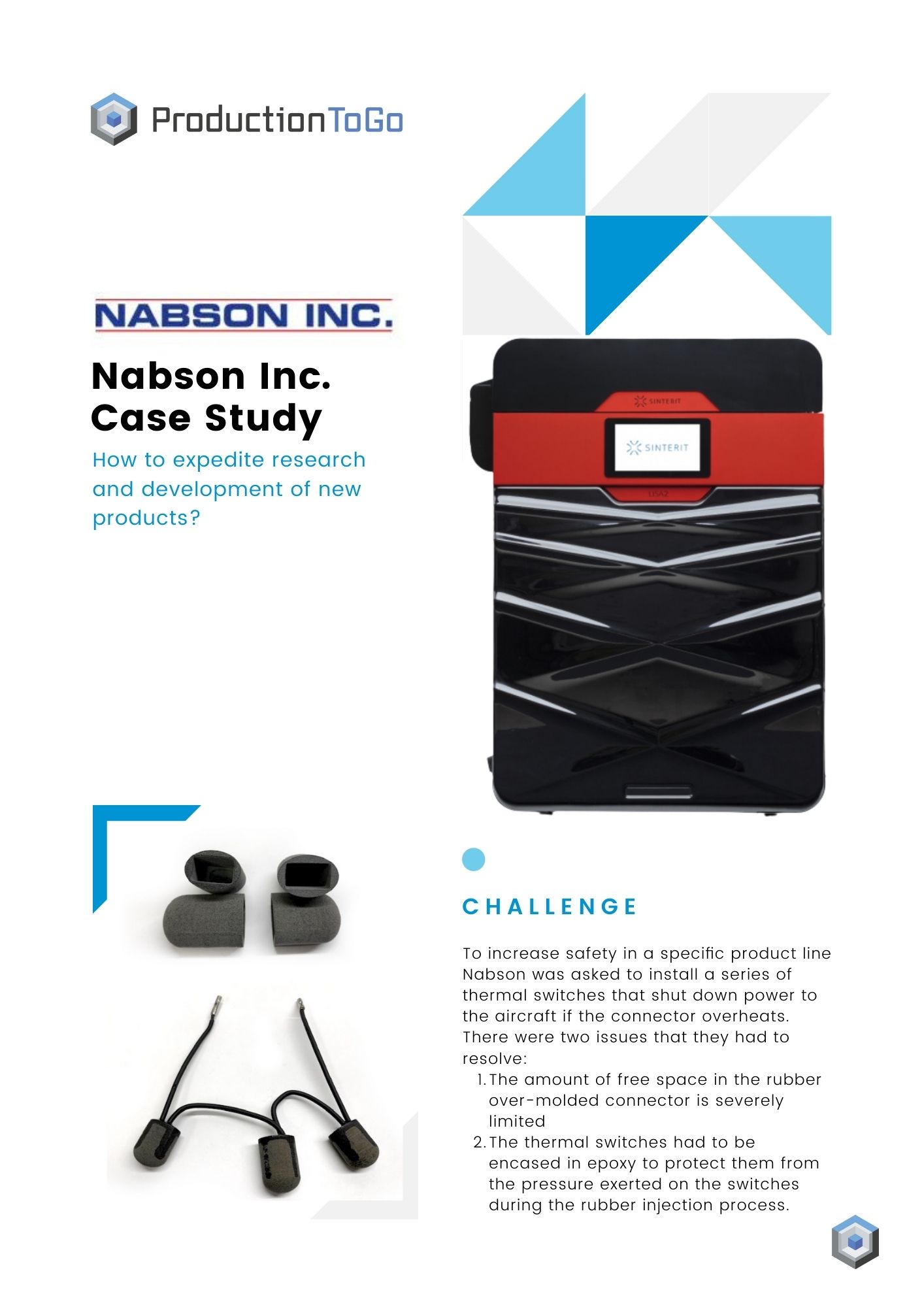

To increase safety in a specific product line Nabson was asked to install a series of thermal switches that shut down power to the aircraft if the connector overheats. There were two issues that they had to resolve: 1. The amount of free space in the rubber over-molded connector is severely limited 2. The thermal switches had to be encased in epoxy to protect them from the pressure exerted on the switches during the rubber injection process.

Fill up the form below and we will send you the use case by e-mail.

Fast prototyping has been a critical factor to reduce the time of development. The company used to have a couple of suppliers for 3D printing, but they needed more efficiency. They design products and molds internally, so the opportunity to have a real piece even in an early stage is beneficial. In the past, they would have to manually modify the pieces to simulate the modification, but it was not possible in some case. If in a hurry, they would modify the molds step by step until reaching the final result.

Fill up the form below and we will send you the use case by e-mail.

The company’s products are designed to be compatible with a variety of laboratory glassware and equipment. As such, they require flexible production techniques, as customers have broad expectations. The demand for such elements at relatively low volumes has put aquila biolabs in a tricky position. Custom manufacturing of each configuration would be costly and time-consuming. Also tooling for mass production for so many variants would be too large an investment. These challenges led them to search for a 3D printer for their application.

Fill up the form below and we will send you the use case by e-mail.

In the past, ECA Medical outsourced its parts to get them printed, which not only cost a significant amount of money but also took many weeks at times. They also often did not have control of tolerances when outsourcing or received parts that didn't work due to the mating components. Previously they used only in-house mold injection. When designing parts it is difficult and highly labor-intensive to do any type of interactive testing or prototyping. If there was anything wrong with the model, they needed to change the design and start the whole process again.

Fill up the form below and we will send you the use case by e-mail.

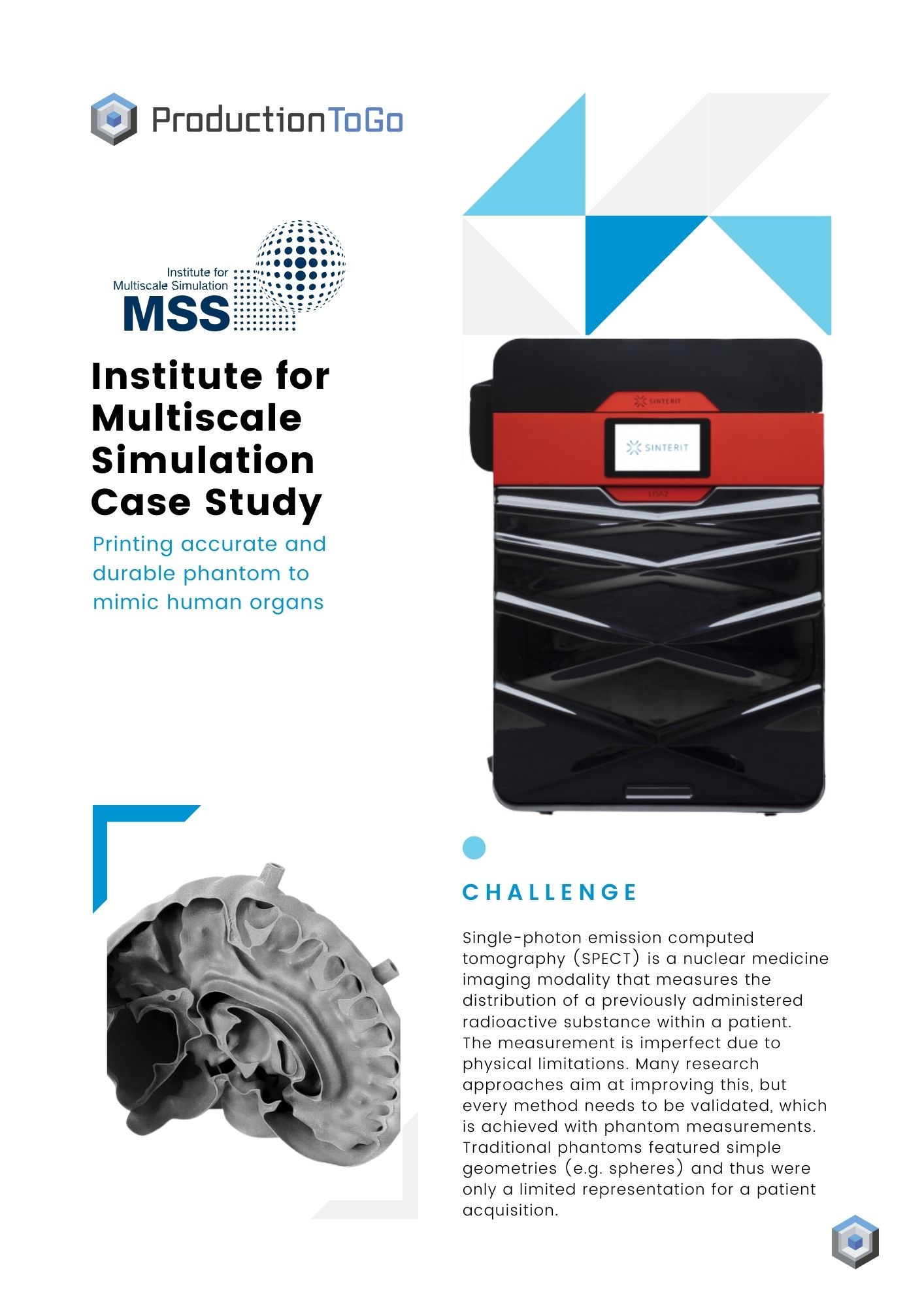

Single-photon emission computed tomography (SPECT) is a nuclear medicine imaging modality that measures the distribution of a previously administered radioactive substance within a patient. The measurement is imperfect due to physical limitations. Many research approaches aim at improving this, but every method needs to be validated, which is achieved with phantom measurements. Traditional phantoms featured simple geometries (e.g. spheres) and thus were only a limited representation for a patient acquisition.

Fill up the form below and we will send you the use case by e-mail.

Formula Student is a racing league that pushes the limits of the volunteer teams to extreme engineering feats. Formula Student, as the name implies, means the team is made up of student volunteers and funded by donations and sponsorships. As such, frugality is a key design principle for many subsystems. When the team can’t get sponsorships for parts it is debated whether to buy off-the-shelf components using their limited budget or to make a solution from their available resources.

Fill up the form below and we will send you the use case by e-mail.

Speed of reaction, freedom of design, and cost- efficient production were the most common challenges to fulfil customer needs. Wide choice and frequent material changes have also been a pinnacle to satisfy customer demands. Partnerships with large, industrial powder bed printing partners did not allow them to achieve desired flexibility and efficiency. Therefore, Netsheipas AM searched for compact, flexible, and efficient SLS solutions in the market, which would be the best fit for complex, engineered grade performance components.

Fill up the form below and we will send you the use case by e-mail.

Almost no manufacturers want to focus on classic car spare parts because the production volumes are too low. No manufacturing technology is cost-effective enough to bridge that gap, except 3D printing, which is an excellent opportunity for all classic car lovers like OctoClassic. Finding new parts suitable for 3D printing became their hobby and mission. There are plenty of parts in cars which are either difficult to find on the aftermarket or costly. This is the scenario that happened to the classic Mercedes owner who needed to replace the power steering fluid cap, which is not available on the market.

Fill up the form below and we will send you the use case by e-mail.

REGNER is a well-known OEM provider of motion control solutions, from control boxes to linear actuators, that bases its success on providing world-class support in a market that moves very quickly. Each actuator is designed to meet the requirements of each customer. Although they may have a similar appearance, the housing design is thoroughly developed and tested to meet specific requirements and deliver the highest performance. This is a precise job considering the many moving parts involved in a linear actuator. Friction or wear can lead to failure. The parts must have a high level of resistance.

Fill up the form below and we will send you the use case by e-mail.

Rotite is an innovative low profile, high strength, fastening technology used in various applications (e.g., hermetic USB connectors, strap fastenings for baby seats to composite panel fastening in the automotive sector). As an agile business, development time and time to market are critical for Rotite Technologies for developing their products. The geometry of their patented technology requires careful planning and expensive specialized tooling to manufacture using injection molding. Other methods of manufacture have substantial price barriers.

Fill up the form below and we will send you the use case by e-mail.

|

|

Watch the video |

|

|

Watch the video |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy