3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

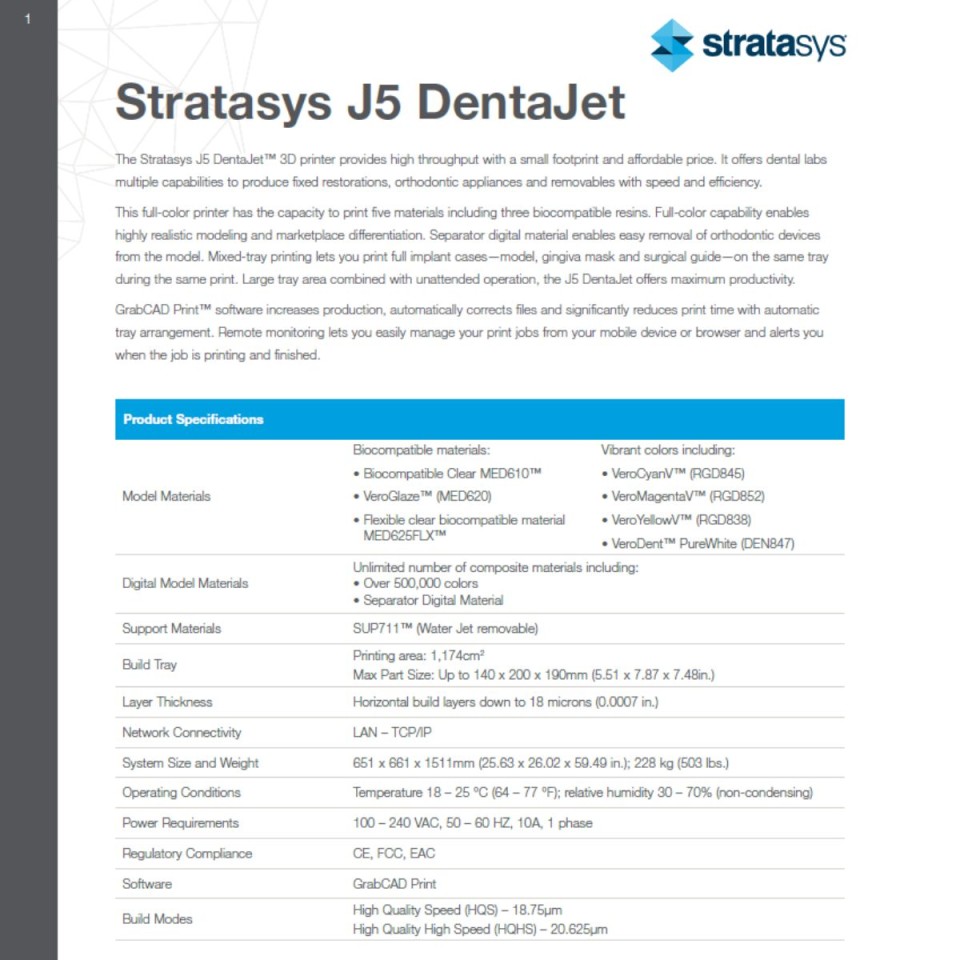

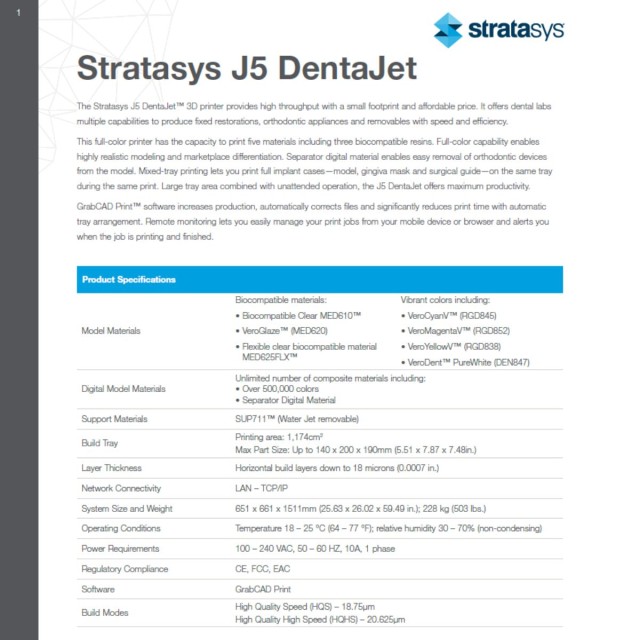

Established more than 20 years ago, PS Dental Laboratory Linz is a leading expert in the production of dental prosthetics in Linz, Austria. In response to feedback from dentists and dental labs, the dental lab invested in new digital equipment and technology, including 3D printing. Over the past few years, the dental lab has become an expert in 3D printing for dental models, but it lacked the layer accuracy and full-color printing capabilities needed to produce customized dental models.

Fill up the form below and we will send you the use case by e-mail.

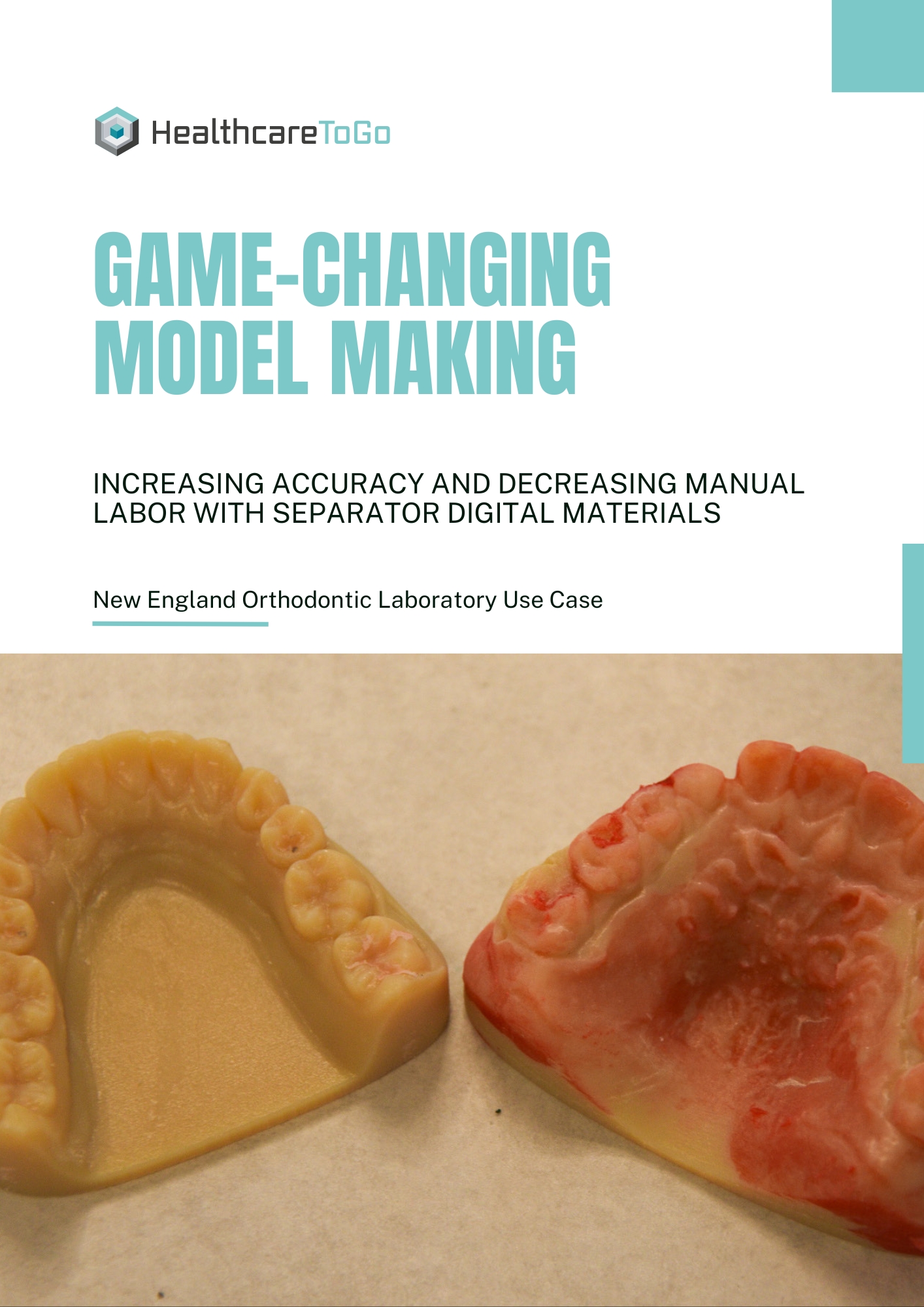

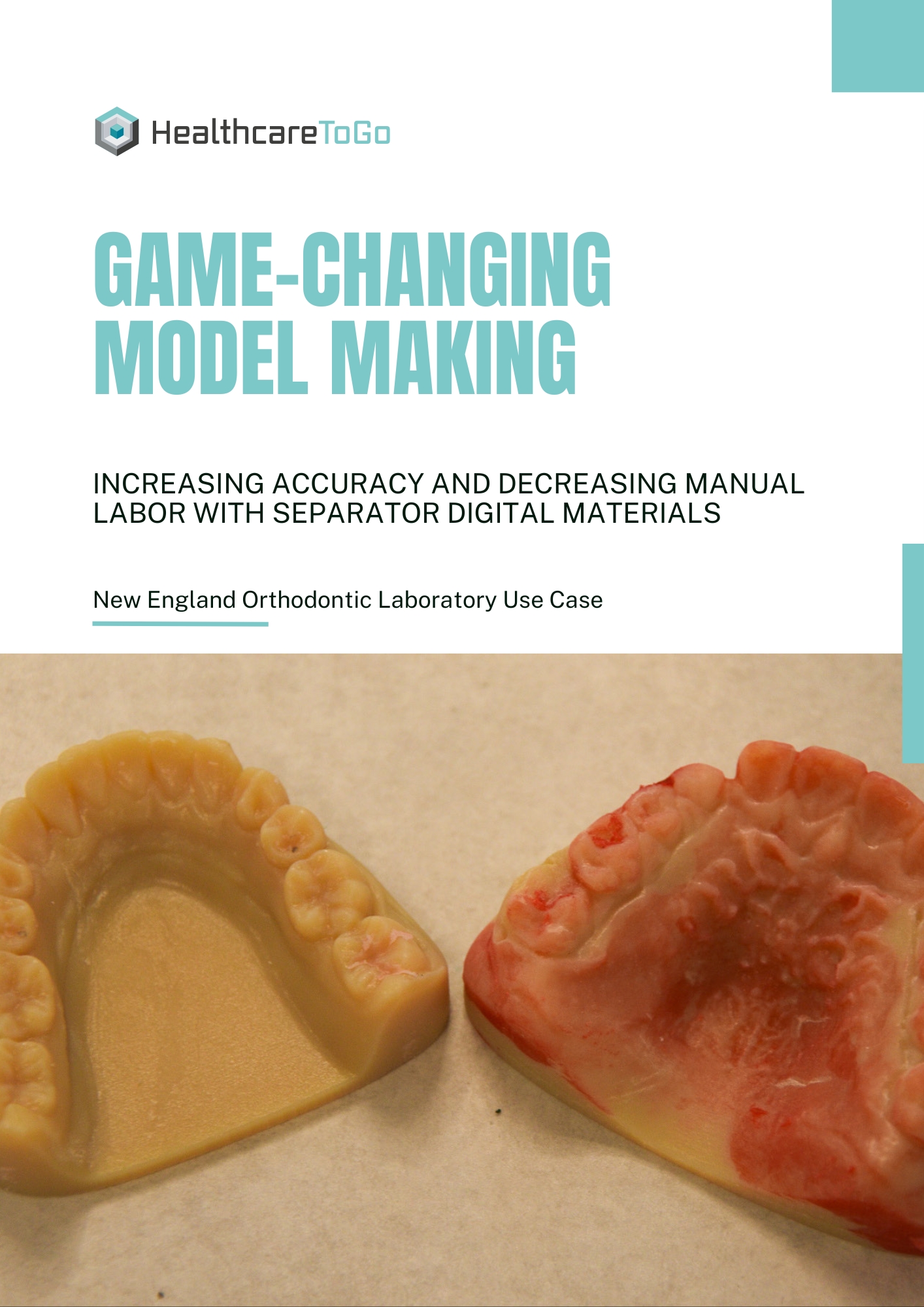

During a visit with Christian Saurman, the CEO of NEO Lab, the Stratasys® team wanted to learn how our technologies could make the day-to-day easier for their 120 employees who work with about 3,000 orthodontic and pediatric dental clinics around the country. Saurman explained how time-consuming and messy it is to create acrylic devices using a traditional separator liquid because it requires careful application and it tends to bleed around the model. It also takes longer to dry and because it’s hard to remove the appliance from the model, the model can easily crack.

Fill up the form below and we will send you the use case by e-mail.

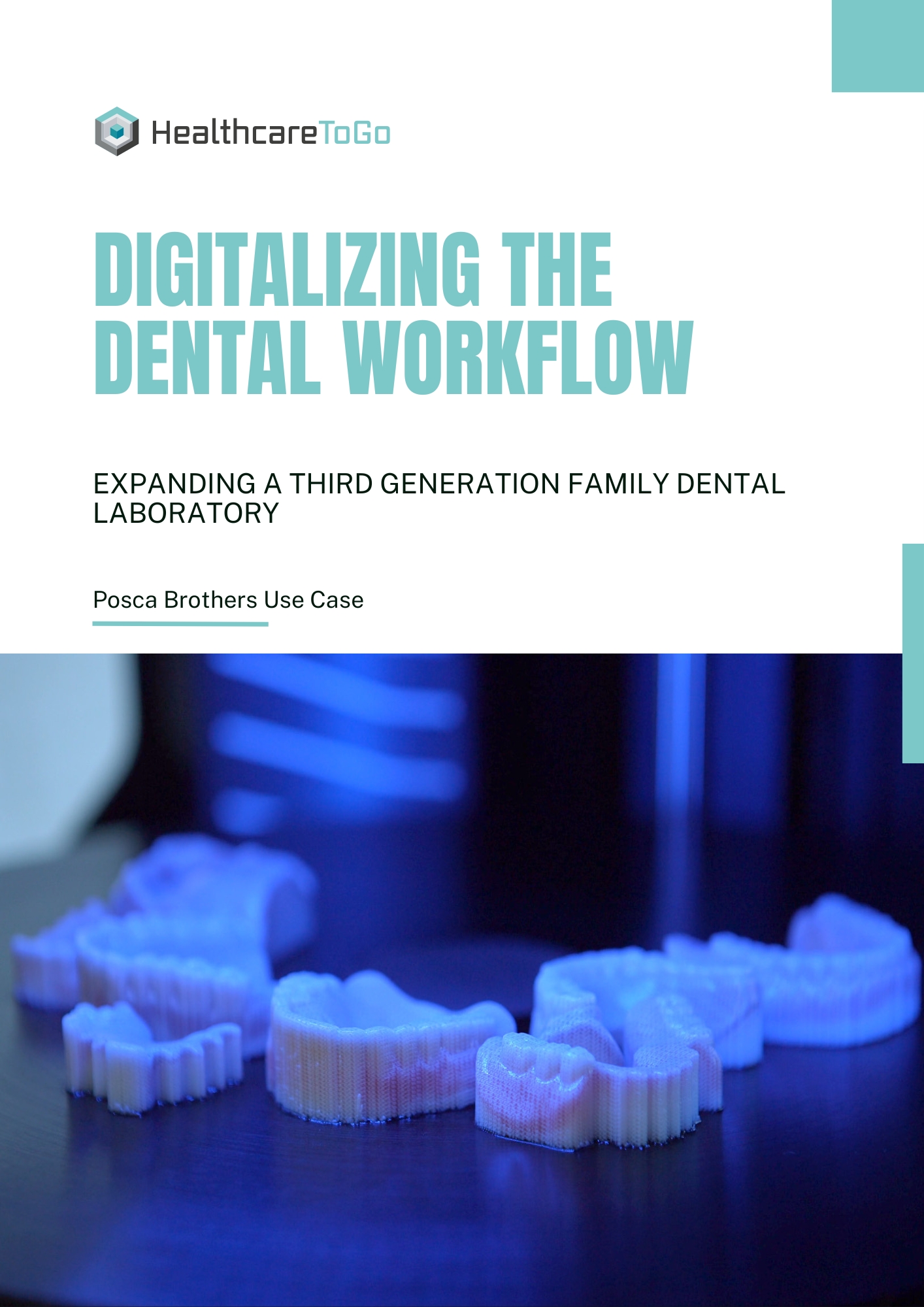

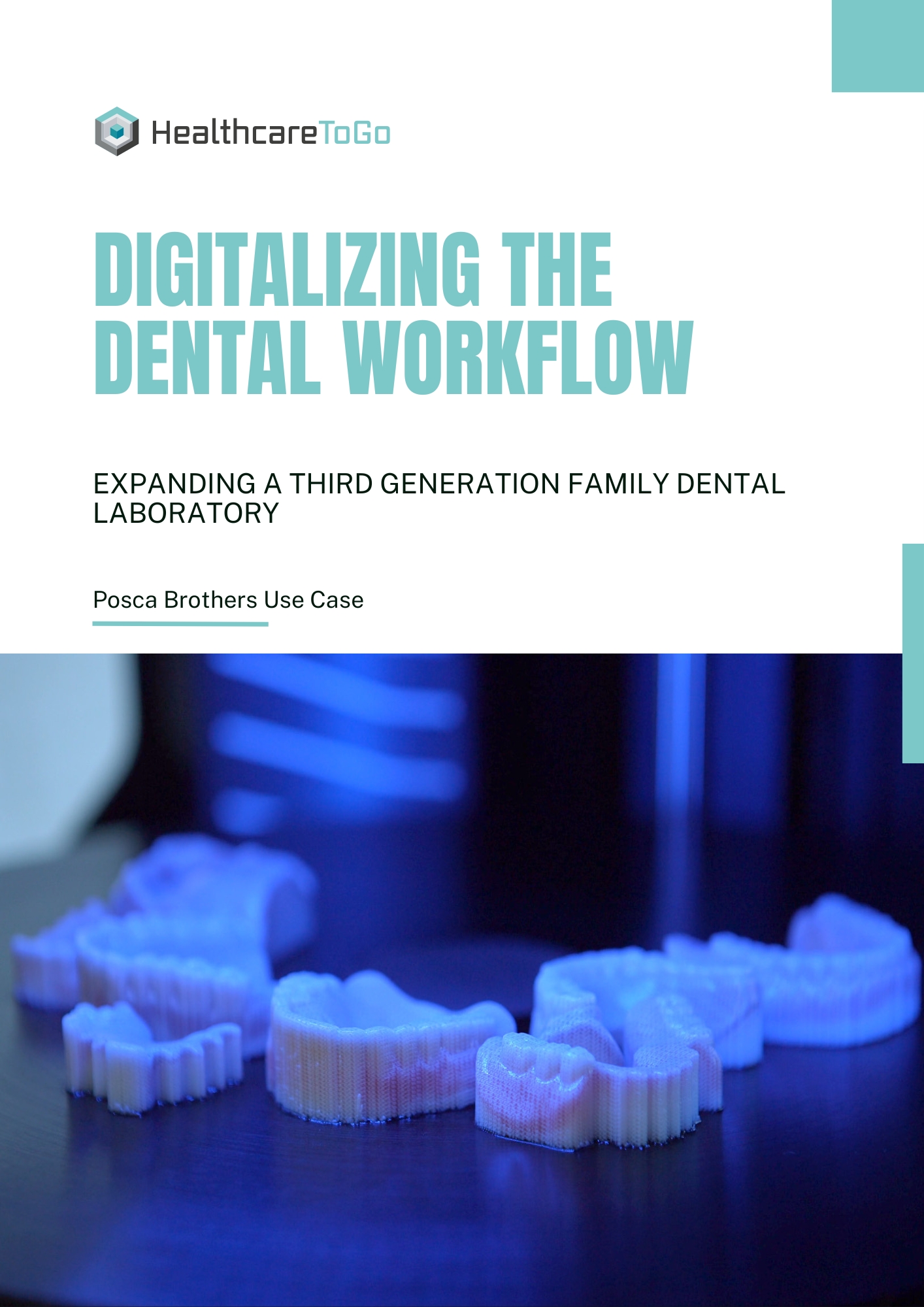

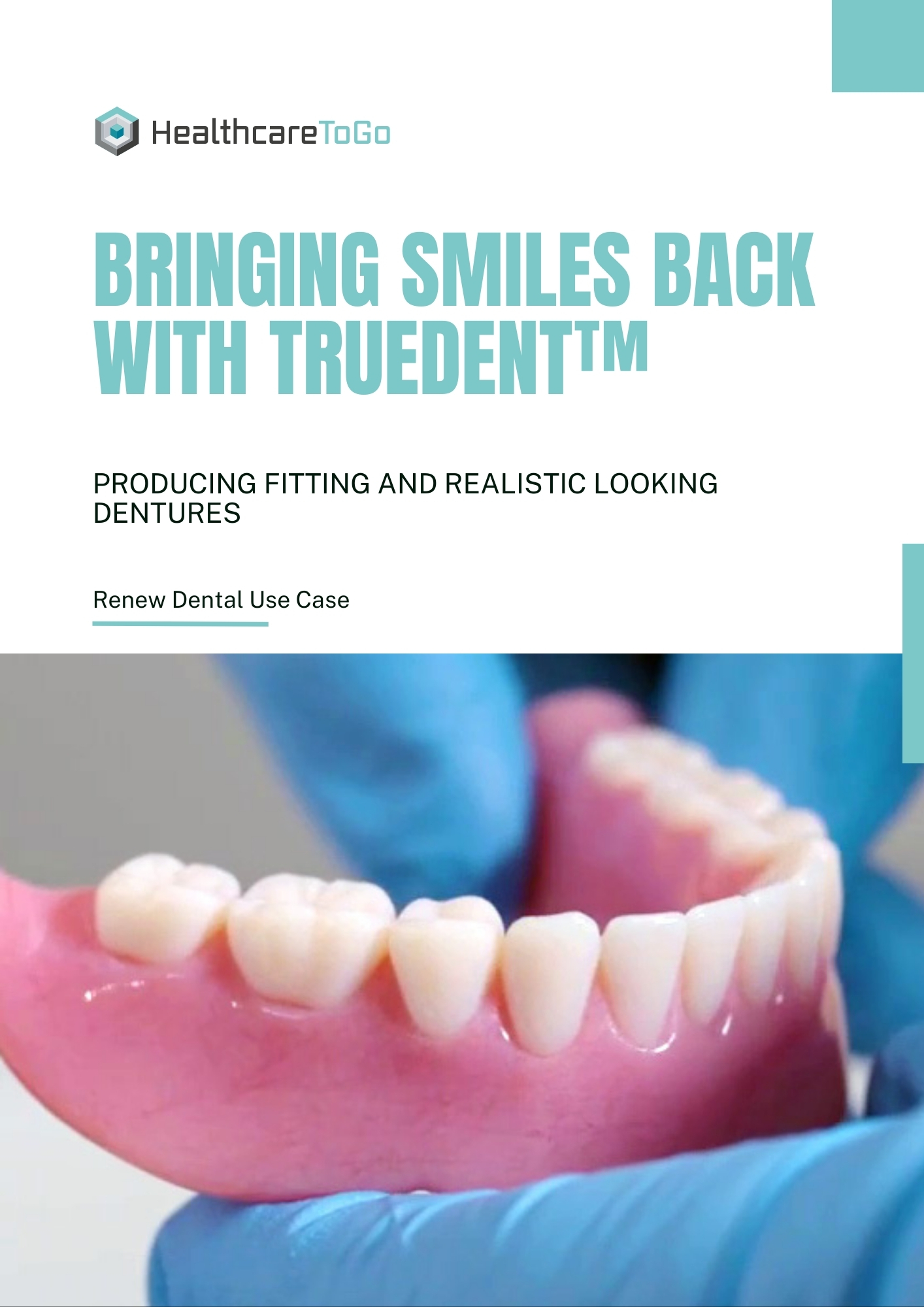

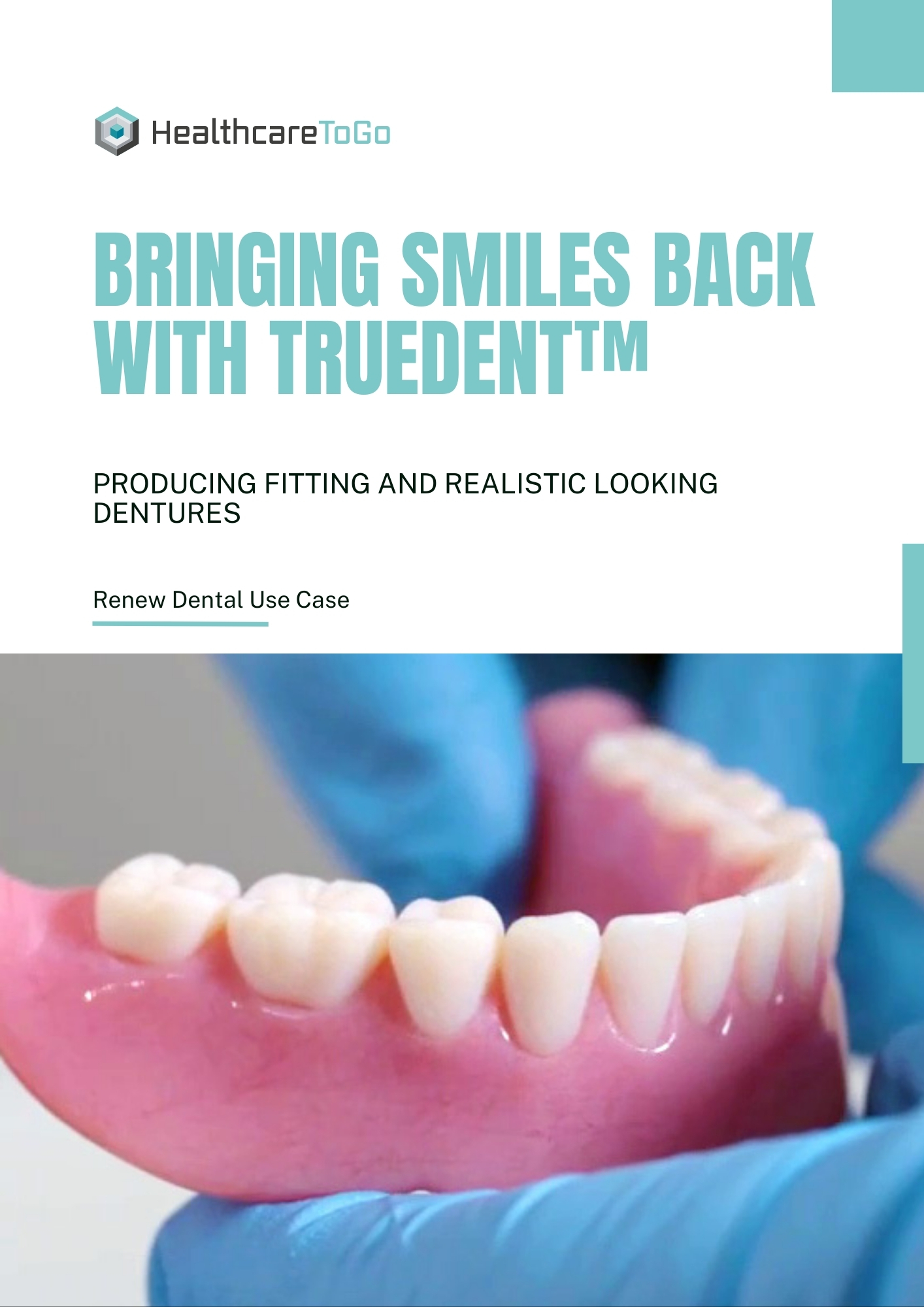

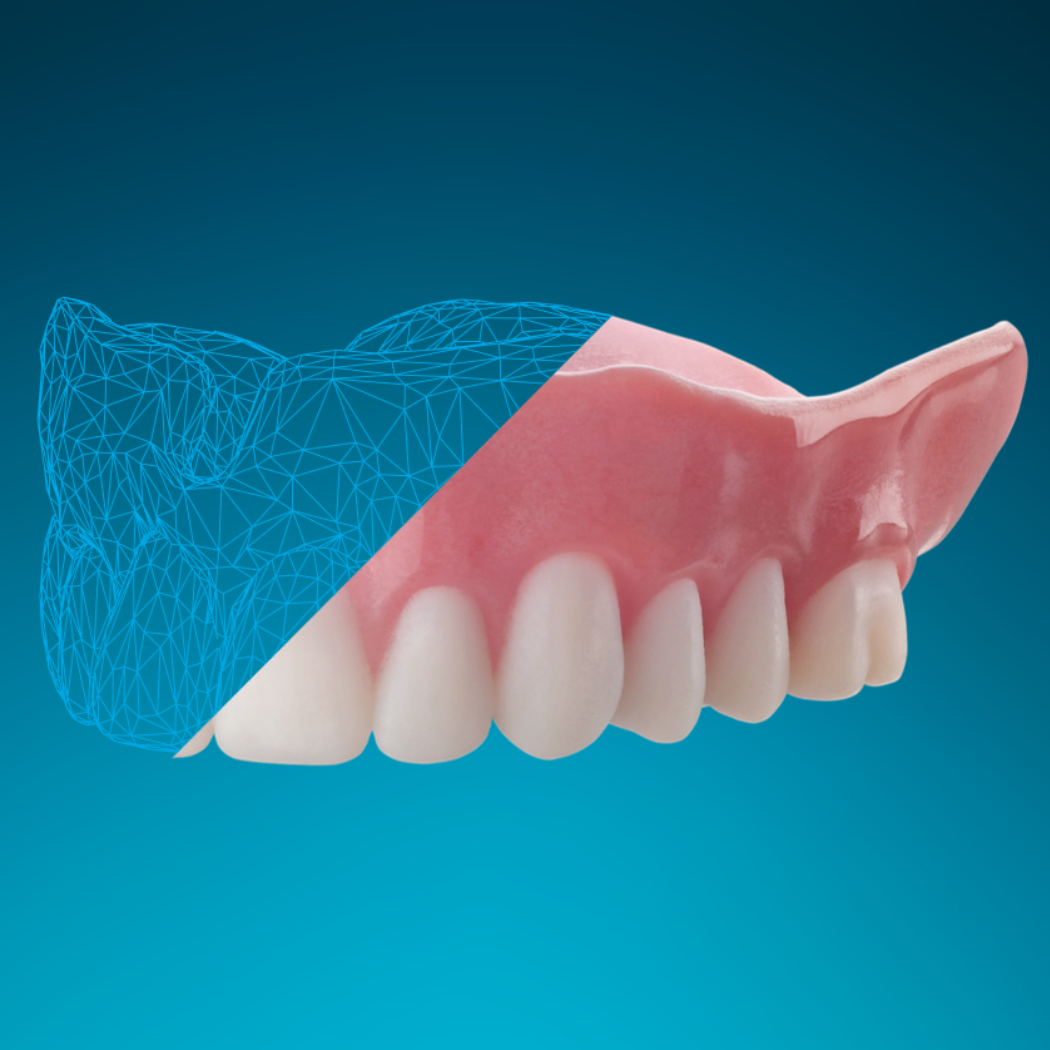

A dental laboratory based in Long Beach, California, was one of the first labs to adopt TrueDent™, Stratasys®’ new resin for 3D printing of dentures and temporary crowns and bridges. The lab, Posca Brothers, is run by owners Alex Posca, President, and AJ Posca, who serves as the Vice President and Director of Operations and was founded by their grandfather. “After 65 years of servicing dental professionals, I am part of the third generation responsible for running this laboratory and ushering it into the digital and 3D printing age,” AJ explained.

Fill up the form below and we will send you the use case by e-mail.

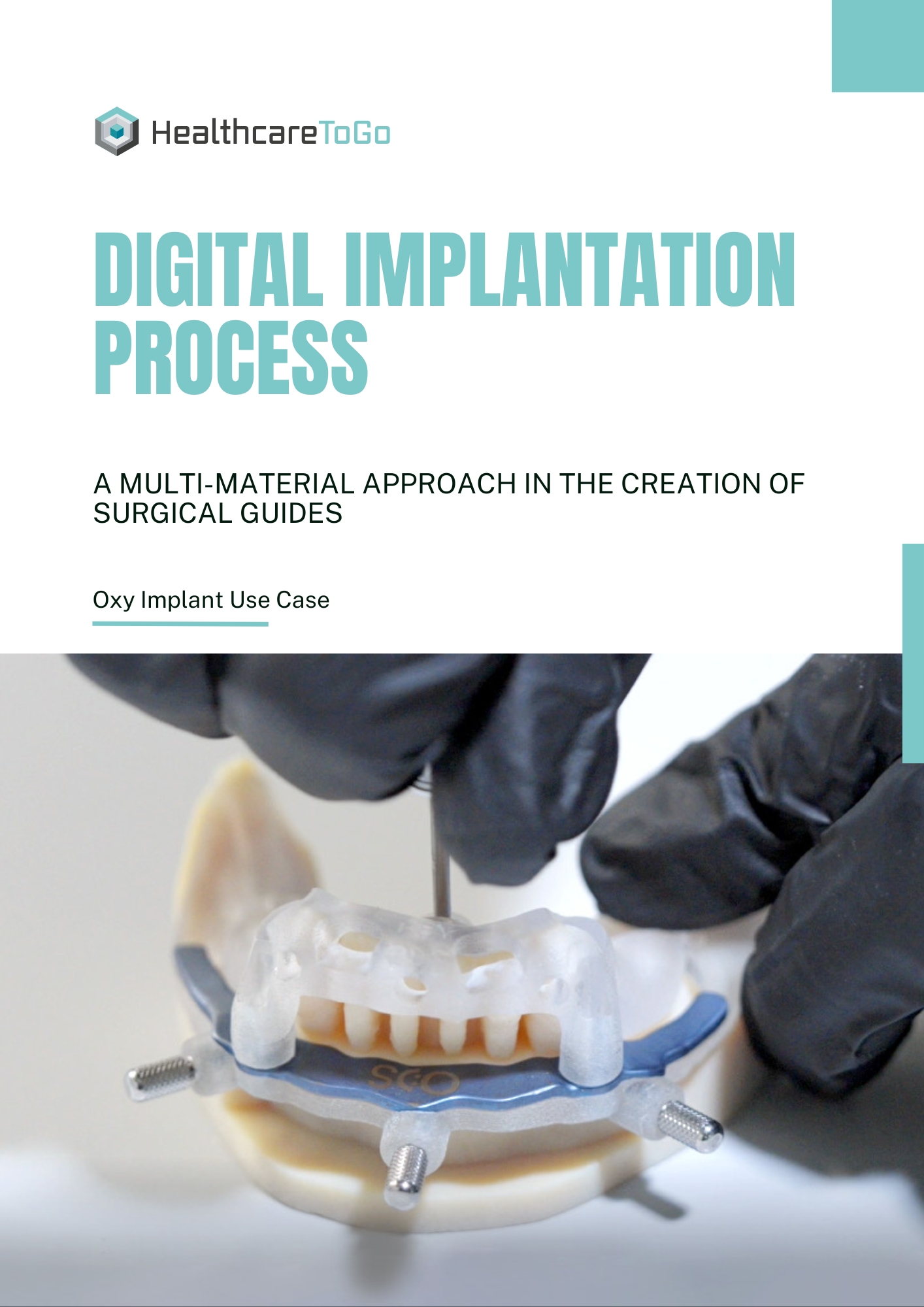

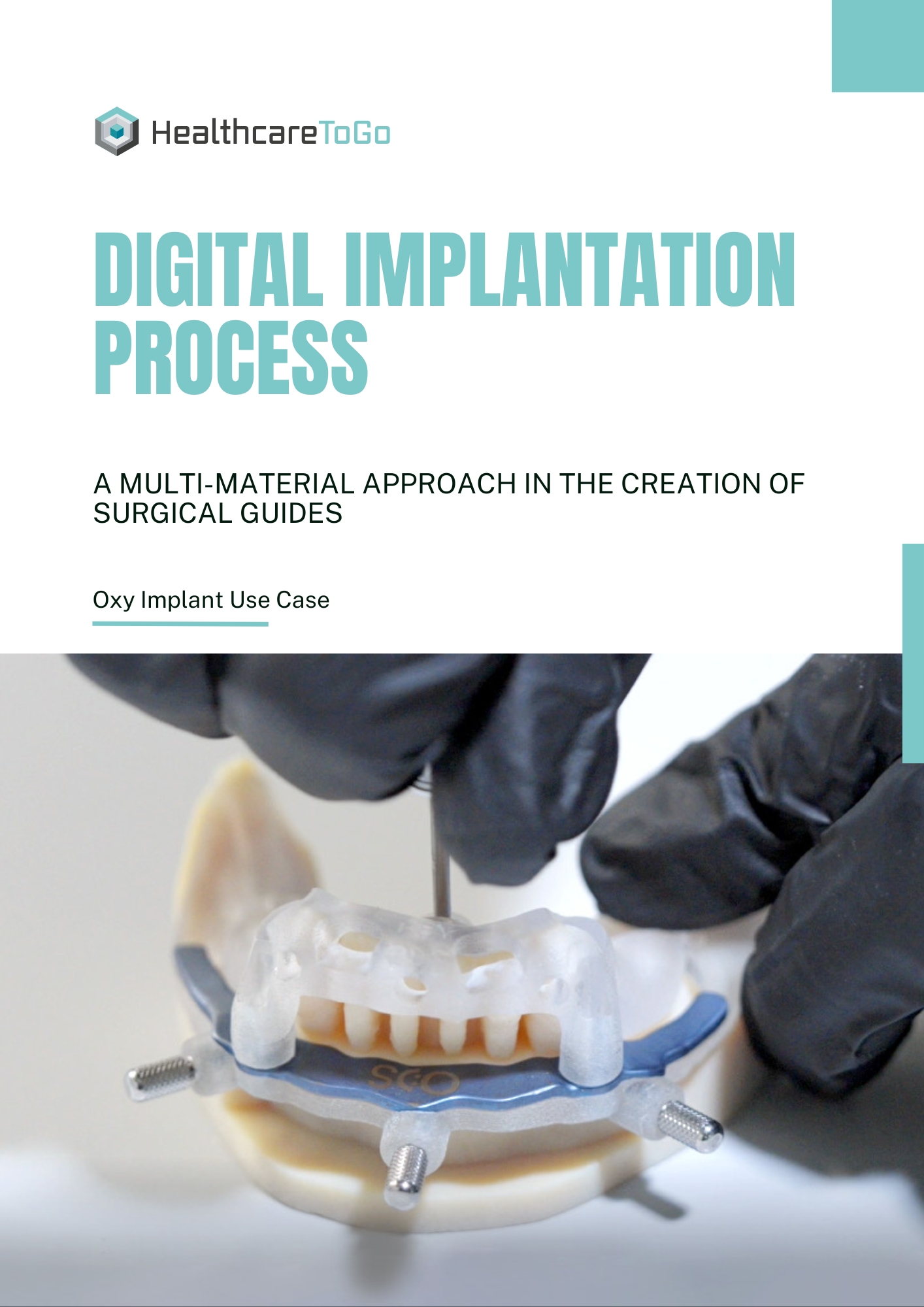

Since it was established in 1990, Oxy Implant has stayed at the forefront of digitalization as it has become a larger part of the overall dental industry. With the industry’s paradigm putting the prosthesis at the center of the rehabilitation plan, the best practice workflows must run backwards from the desired prosthetic outcome to develop a plan for achieving this goal. To respond to this change, Biomec began to work on implant fixtures with designs optimized for this type of working philosophy. An implant line was developed that exclusively accommodates the needs of digital implantology, the Fixo™ Line.

Fill up the form below and we will send you the use case by e-mail.

Renew Dental in Phoenix, Arizona, offers patients high-quality dental care, including TrueDent™ dentures. Candice Baier-Gregory came to Renew Dental for precisely these dentures, as her traditionally manufactured dentures did not provide the stability she needed to smile with confidence in her daily life. Find out how TrueDent™ finally provided the patient with perfectly fitting dentures!

Fill up the form below and we will send you the use case by e-mail.

The Oklahoma Mission of Mercy (OkMOM) is a two-day free dental clinic that provides treatment to patients who lack insurance or adequate insurance or who would not normally have access to dental care. Find out how partnering with Stratasys® has helped treat more patients in less time in this use case!

Fill up the form below and we will send you the use case by e-mail.

|

|

Photos of the Event |

|

|

Photos of the Event |

|

|

On-Demand Webinar |

|

|

On-demand Webinar |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy