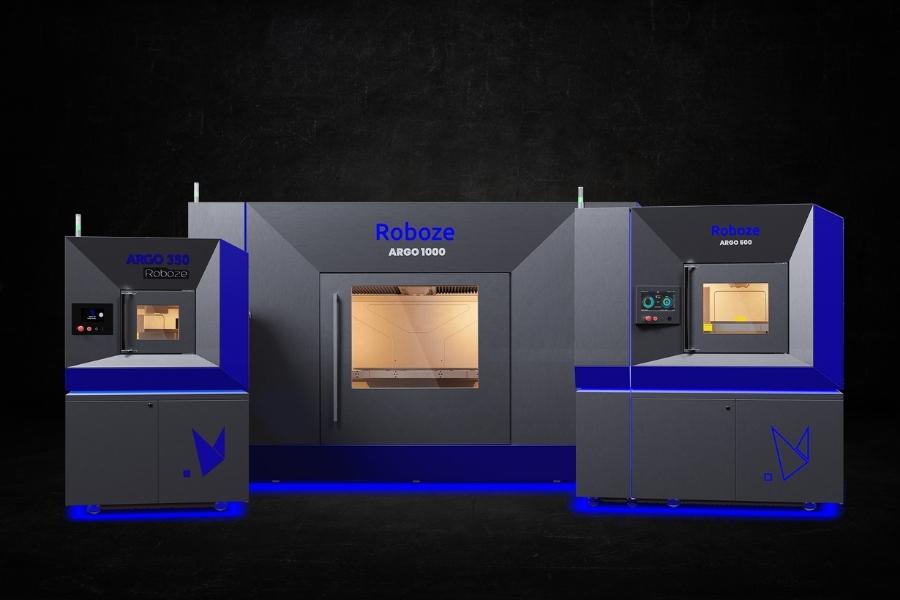

3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

PUNCH Torino is specialized in the design and development of innovative propulsion systems and advanced technologies. Founded in 2005 by General Motors, it became part of the PUNCH Group, a leading supplier for the development, integration and production of transmissions and powertrains, in 2020. As part of its product development activities, PUNCH Torino was looking for an industrial 3D printing solution that could meet the versatility and precision requirements for applications related to high performance polymeric materials.

Fill up the form below and we will send you the use case by e-mail.

The world of motorsport is one of the most driving forces for innovation where new performances can make the difference between a first and a second place. Ducati Corse was looking for a new solution capable to help them validate their designs with robust and repeatable 3D printing technology to speed up the design phases of functional prototypes and finished parts. The goal was to drastically reduce the time between design and track tests, ensuring mechanically performing parts even at high temperatures.

Fill up the form below and we will send you the use case by e-mail.

Conventional methods for producing oil and gas impellers have certain limitations that can impact the production process and the performance of the final product. When impellers are manufactured via casting, they are often unbalanced because of uneven flow of the metal in the mold. This causes vibrations and leads to fatigue failure and shorter lifespans. Companies therefore need to balance impellers after casting. Another problem is that the process of manufacturing through casting requires a long time, making the lead time very long.

Fill up the form below and we will send you the use case by e-mail.

Manufacturers and end-users have faced problems for a long time with pumps that have mating components made of cast iron, stainless steel, and bronze. The abrasive nature of these metals causes wear in pump parts, leading to galling and seizing that frequently results in failures. The conventional method of production of oil and gas wear rings involves the use of traditional manufacturing techniques such as casting, machining, and forging. One limitation of the conventional method is that it can be time-consuming and expensive.

Fill up the form below and we will send you the use case by e-mail.

The disk is part of the opening mechanism of swing check valves trim in the Energy industry. It was originally manufactured in Carbon Steel but it corroded quickly because of the presence of hydrocarbons. Common corrosive environments may include the chemical industry, wastewater treatment and many others. Each environment presents specific corrosion challenges due to the presence of aggressive chemicals, salinity or humidity. Super Duplex was thought of as a replacement. However, this option would have been more expensive.

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy