3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

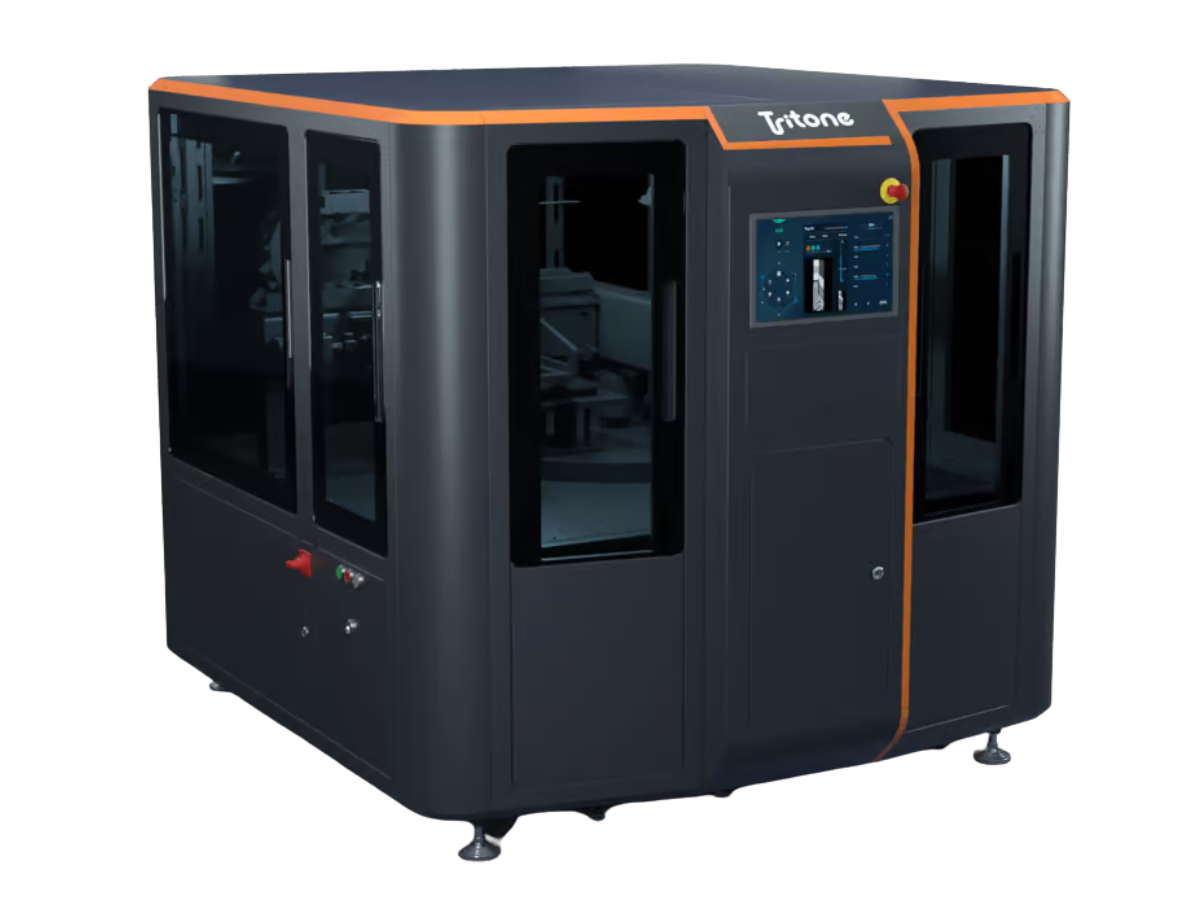

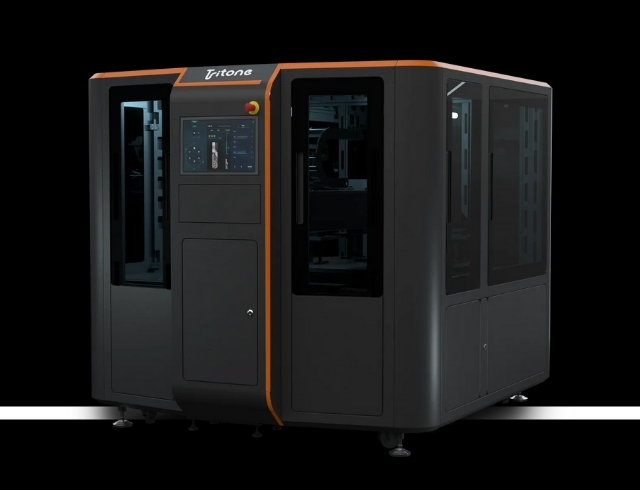

The Tritone Dim System is a compact, industrial 3D printer designed for metal and ceramic additive manufacturing using unique powder-free MoldJet® technology. It features four simultaneous, independent trays and can print layer thicknesses down to 25 microns.

The Tritone Dim System is a mid-range industrial additive manufacturing solution that balances compact design with robust production capabilities. It leverages Tritone’s unique MoldJet® powder-free technology to deliver high precision and repeatability in metal and ceramic manufacturing, ideal for R&D, material qualification, and small to medium batch production.

Built to fit in smaller spaces without compromising performance, the Dim system offers four independent build trays, each with a 220 × 120 × 90 mm build volume, supporting simultaneous and diverse manufacturing runs. It features adjustable layer thickness from 25 to 150 microns and a throughput of 220 cc/h, enabling manufacturers to optimize speed, detail, and material use while maintaining consistency. The system is designed for wide material versatility including metals and ceramics, and a clean, safe working environment with hands-free post-processing and low energy consumption.

Technical Specifications:

Number of trays: 4 simultaneous and independent

Tray build volume: 220 × 120 × 90 mm

Total build volume: 10,000 cc

Throughput: Up to 220 cc per hour

Nominal layer thickness: Adjustable from 25 – 150 μm

The Dim system supports uniform, repeatable manufacturing with high packing density (>99%) across four independent trays, allowing parallel production of multiple parts or batches. AI-driven real-time quality inspection and corrections minimize defects, ensuring reliable, consistent output even in complex part sets.

Tritone Dim offers broad compatibility with metal and ceramic powders (in paste form) based on standard MIM powders. The quick, clean material changeover enhances flexibility for R&D and small batch production, allowing users to test and qualify multiple materials with ease and maintain contamination-free processes.

By adopting a powder-free paste-based feedstock, Dim eliminates hazards related to powder handling while providing a cleaner and environmentally friendly workspace. The hands-free post-processing workflow reduces operator intervention and exposure, and its low energy consumption fits readily in standard industrial settings.

With a footprint designed for smaller production floors and labs, Dim enables easy integration where space is limited. Independent tray operation allows running multiple jobs simultaneously, supporting varied production requirements and testing applications without disrupting ongoing jobs.

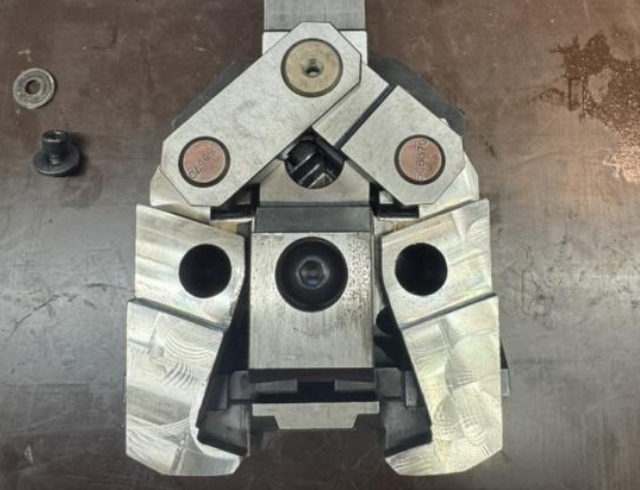

Adjustable layer thickness down to 25 microns allows Dim to achieve fine geometric details and smooth surface finishes, crucial for advanced applications in medical, aerospace, and precision tooling sectors. This precision ensures parts meet demanding mechanical and aesthetic standards.

Dim’s streamlined integration of feedstock preparation, printing, quality inspection, and post-processing reduces downtime and manual labor. This cohesive workflow enables faster iteration cycles and effective scaling from development to low-volume production.

Produce high-strength, lightweight aerospace parts with intricate geometries and precise tolerances.

Manufacture intricate medical implants with biocompatible metals, delivering high-resolution features crucial for personalized patient care.

Rapidly produce durable tooling components with complex features with accelerated tool iteration cycles and cost efficiency.

Enable large-scale and batch production of robust consumer electronics components with precise surface finish and complex geometries.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy