3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

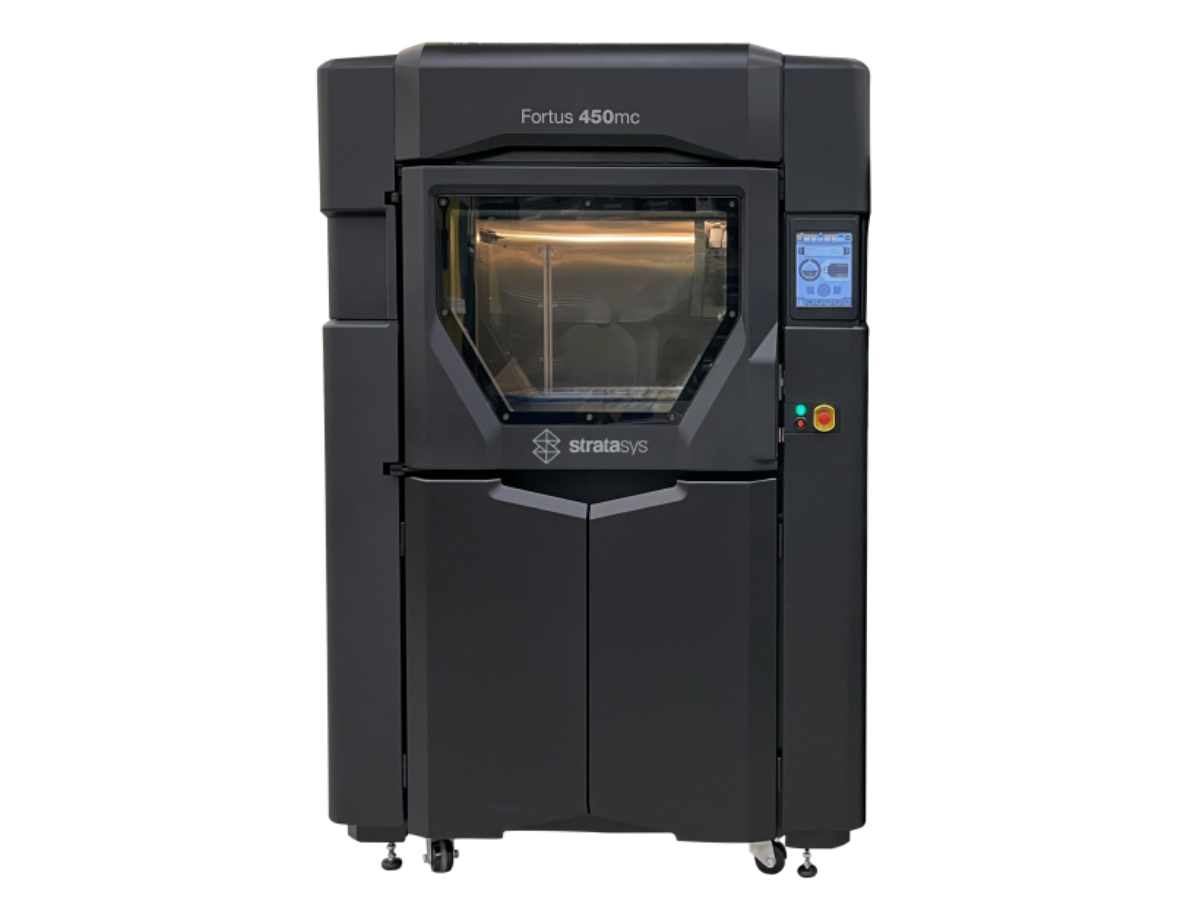

The Stratasys® Fortus 450mc Gen3 is a professional industrial FDM 3D printer designed to deliver high-strength, precise, and repeatable parts for demanding manufacturing environments.

Combining advanced FDM technology with a large build volume and enhanced material compatibility, the Stratasys® Fortus 450mc Gen3 is optimized for versatile applications across aerospace, automotive, and general industry sectors.

This next-generation Fortus 450mc offers fully hardened components for seamless printing with composite and filled materials, broadening material options including new glass-filled nylons and recycled PET-G composites. It features an expanded material capacity with dual 250 ci spools and advanced drying capabilities through the Fortus FDC™ material delivery cabinet, ensuring consistent print quality and longer uninterrupted operation. Integrated with GrabCAD Print Pro software, it streamlines your workflow with precise control over printing parameters and cost management tools, making it ideal for cost-effective low-volume production, functional prototyping, and replacement parts.

With a build envelope of 406 × 355 × 406 mm, the Fortus 450mc Gen3 supports 16 material grades, including standard, engineering, and high-performance thermoplastics like Nylon 12CF, ULTEM 9085, ASA, PC-ABS, and Antero. The system achieves dimensional accuracy within ±0.127 mm or ±0.0015 mm/mm, ensuring near-isotropic parts with over 80% strength in the vertical plane for demanding structural and environmental performance. The Gen3 model further optimizes print speeds and durability with a new T40 printer tip, making it a reliable choice for factory-floor-ready additive manufacturing.

Technical Specifications:

Build Volume: 406 × 355 × 406 mm

Achievable Accuracy: ±0.127 mm (±0.005 in) or ±0.0015 mm/mm

Material Delivery Options: up to 500CI with Fortus FDC™ drying cabinet

The Fortus 450mc Gen3 features fully hardened components that make it capable of printing abrasive composite and filled materials such as Nylon 12CF and Antero without additional hardware or wear kits. This robust design significantly increases the printer’s lifespan and lowers maintenance needs, enabling manufacturers to run demanding, high-strength print jobs reliably with minimal downtime. It also future-proofs the system for new advanced materials, ensuring versatility for evolving industrial applications.

The Gen3 comes with an all-materials license granting access to a comprehensive portfolio of 16 production-grade thermoplastics, including engineering, high-performance, glass-filled nylons, and recycled PET-G composites. This broad material compatibility allows users to tailor parts for specific requirements such as chemical resistance, thermal stability, flame retardance, or mechanical strength. It supports manufacturing of everything from lightweight aerospace components to rugged tooling and end-use parts.

With a spacious build envelope of 406 × 355 × 406 mm (16 × 14 × 16 in), the Fortus 450mc Gen3 accommodates large one-off parts or batch production of multiple smaller parts in a single run. This capability increases throughput while reducing setup and material wastage, enabling more efficient factory floor operation. It provides the flexibility required for a wide range of applications, from prototyping to production tooling.

The printer delivers dimensional accuracy to ±0.127 mm (±0.005 in) or 0.0015 mm/mm and produces parts with near-isotropic strength exceeding 80% in the vertical plane for key materials. This precision and mechanical consistency ensure functional reliability and fit for purpose in critical applications, reducing the need for post-processing or rework. Consistent print success rates of over 90% enhance production reliability.

GrabCAD Print Pro software, included with the system, offers advanced tools such as warp and curl control and part cost estimation, streamlining the digital workflow from CAD to print. This integration reduces setup errors, optimizes material use, and improves traceability and cost management across production jobs. The software’s connectivity also supports factory-floor readiness with job queuing and network security features.

Designed for industrial environments, the Fortus 450mc Gen3 integrates with the Fortus FDC™ material delivery cabinet that dries and stores material spools for continuous operation of up to 500 cubic inches before needing replenishment. Its robust network support and cybersecurity features allow secure and low-attendance production runs, reducing labor and operational disruption. This makes it suitable for scale-up in high-mix, low-volume manufacturing settings.

Produce lightweight, high-strength structural parts and fixtures with ULTEM 9085 and Nylon 12CF materials, meeting strict industry standards.

Create durable jigs, fixtures, and assembling aids that reduce cost and lead time compared to machined alternatives.

Manufacture custom end-use parts and replacement components with superior thermal and chemical resistance in demanding environments.

Develop ergonomic, detailed prototypes and small-batch production parts using versatile materials like ASA and PC-ABS with excellent surface finish and UV resistance.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy