3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

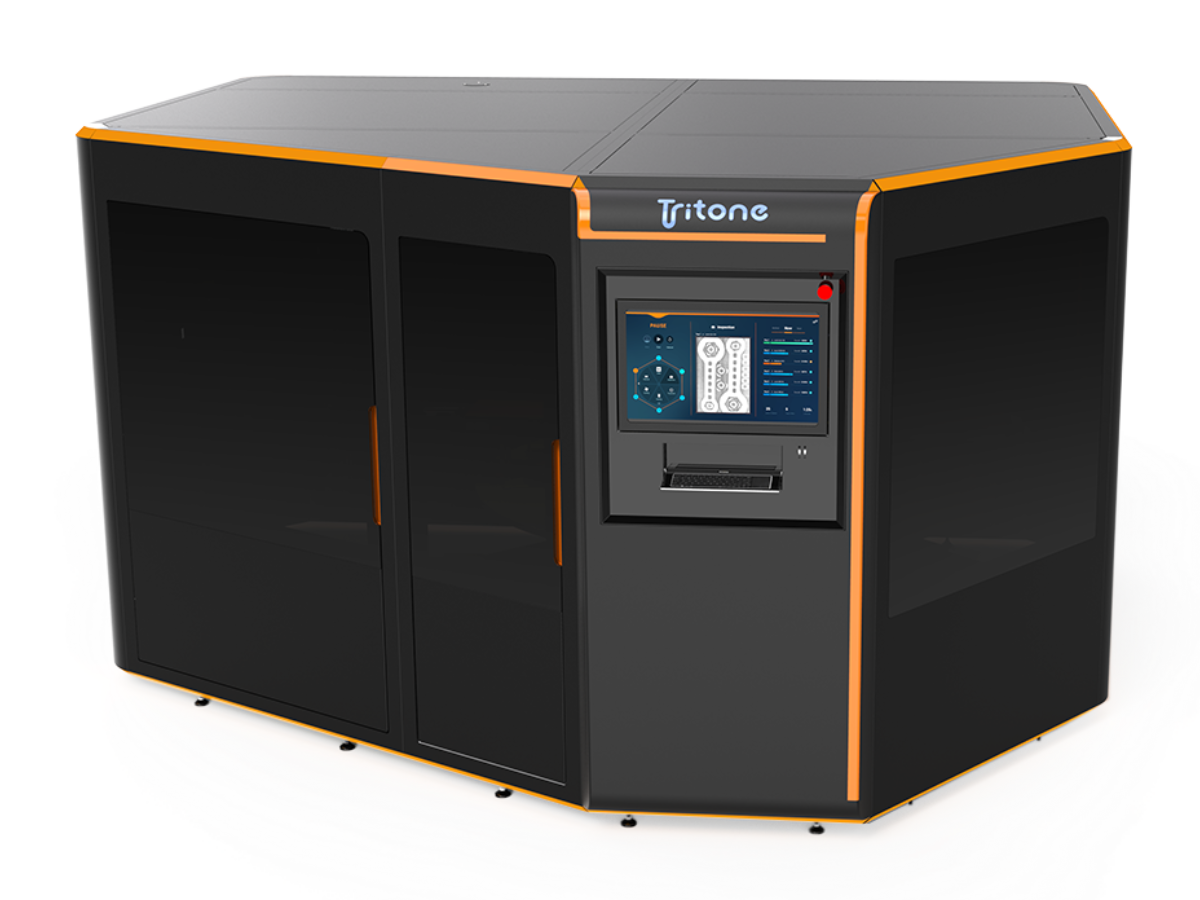

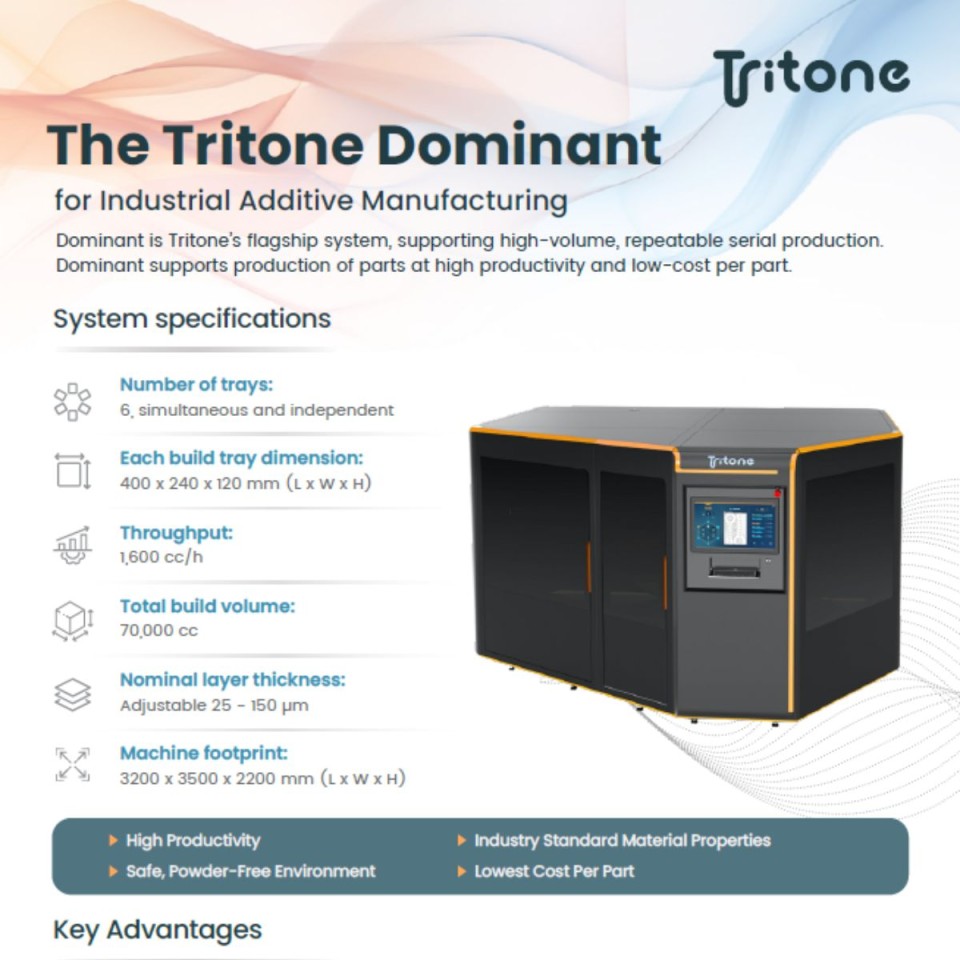

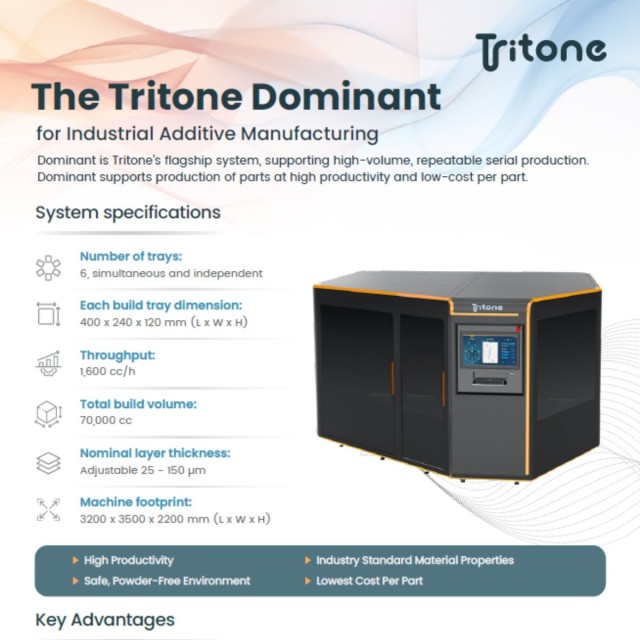

The Tritone Dominant System is an innovative industrial additive manufacturing solution leveraging MoldJet® powder-free technology to produce high-quality metal and ceramic parts at scale.

The Tritone Dominant is a cutting-edge industrial additive manufacturing system designed to enable high-volume, repeatable serial production of complex metal and ceramic parts. Combining innovative MoldJet® technology with AI-powered real-time quality inspection, it delivers exceptional throughput, precision, and material versatility for demanding industrial environments.

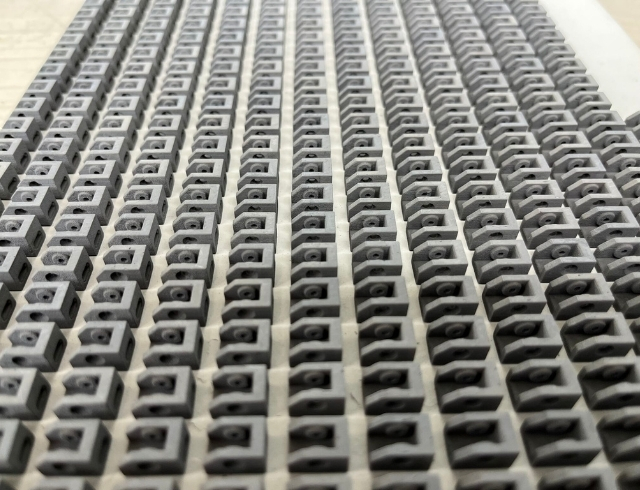

This flagship system features six independent build trays, each offering a build volume of 400 × 240 × 120 mm, allowing simultaneous manufacturing of diverse parts to maximize factory floor productivity. The unique powder-free, paste-based feedstock process creates robust green parts that transition easily to sintering, all within a compact footprint tailored for industrial workflows. With adjustable layer thicknesses between 25 and 150 microns, the Dominant balances speed and fine detail to meet rigorous application requirements from aerospace to tooling and consumer electronics. Real-time AI layer inspection combined with automatic correction ensures consistent quality across trays and builds, enabling dependable serial production with densities up to 99%.

Technical Specifications:

Number of trays: 6 simultaneous and independent

Tray build volume: 400 × 240 × 120 mm

Total build volume: 70,000 cc

Throughput: Up to 1,600 cc per hour

Nominal layer thickness: Adjustable from 25 – 150 μm

The Tritone Dominant’s unique design with six independent build trays allows it to operate multiple print jobs in parallel, drastically increasing throughput to over 1,600 cc per hour. This parallel processing is like having six machines in one footprint, enabling manufacturers to produce thousands of parts simultaneously and significantly accelerating time to market, while maintaining operational flexibility by allowing individual trays to be removed without halting the entire process.

Using MoldJet®'s proprietary paste-based feedstock eliminates the need to handle loose metal powders, which are hazardous and require specialized containment. This powder-free process reduces workplace safety risks and environmental contamination, simplifies regulatory compliance, and creates a cleaner and more operator-friendly production environment. It also reduces cleanup times and costs associated with powder handling in traditional metal additive manufacturing.

Equipped with real-time AI-powered optical inspection, the Dominant system continuously monitors each printed layer for defects or deviations from the design specifications. Defective layers are immediately removed and reprocessed, ensuring that errors do not propagate through subsequent layers. This layer-by-layer quality assurance leads to superior part reliability and minimizes scrap and rework, saving both material and production time.

The system supports a comprehensive range of metal and ceramic materials including titanium, stainless steels, copper alloys, tool steels, and ceramics, made possible by exchanging sealed paste cartridges for different metal pastes. This material flexibility addresses diverse industrial needs, ranging from lightweight aerospace parts to wear-resistant tooling components, allowing manufacturers to adapt quickly to product and market demands without switching machines.

By producing parts with over 99% density and precise layer thickness control down to 25 microns, the Dominant delivers mechanical properties and surface finishes comparable to traditional MIM or wrought materials. This capability ensures parts are robust, with fine details and tight tolerances, meeting stringent quality requirements for aerospace, medical, and high-performance industrial applications.

Green parts produced by the powder-free, MoldJet® process are robust and easy to handle, reducing breakage risk during depowdering and finishing. The parts are chemically released from molds within the machines low-temperature demolding station, enabling clean, residue-free components that transition smoothly into sintering for final densification. This streamlined post-processing reduces labor, cost, and cycle time compared to powder bed methods, facilitating faster scale-up to serial production.

Produce complex, lightweight aerospace parts with exceptional strength, density, and dimensional accuracy.

Create durable, high-tolerance tooling and molds with short setup times and minimal waste.

Enable large-scale and batch production of robust consumer electronics components with precise surface finish and complex geometries.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy