3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

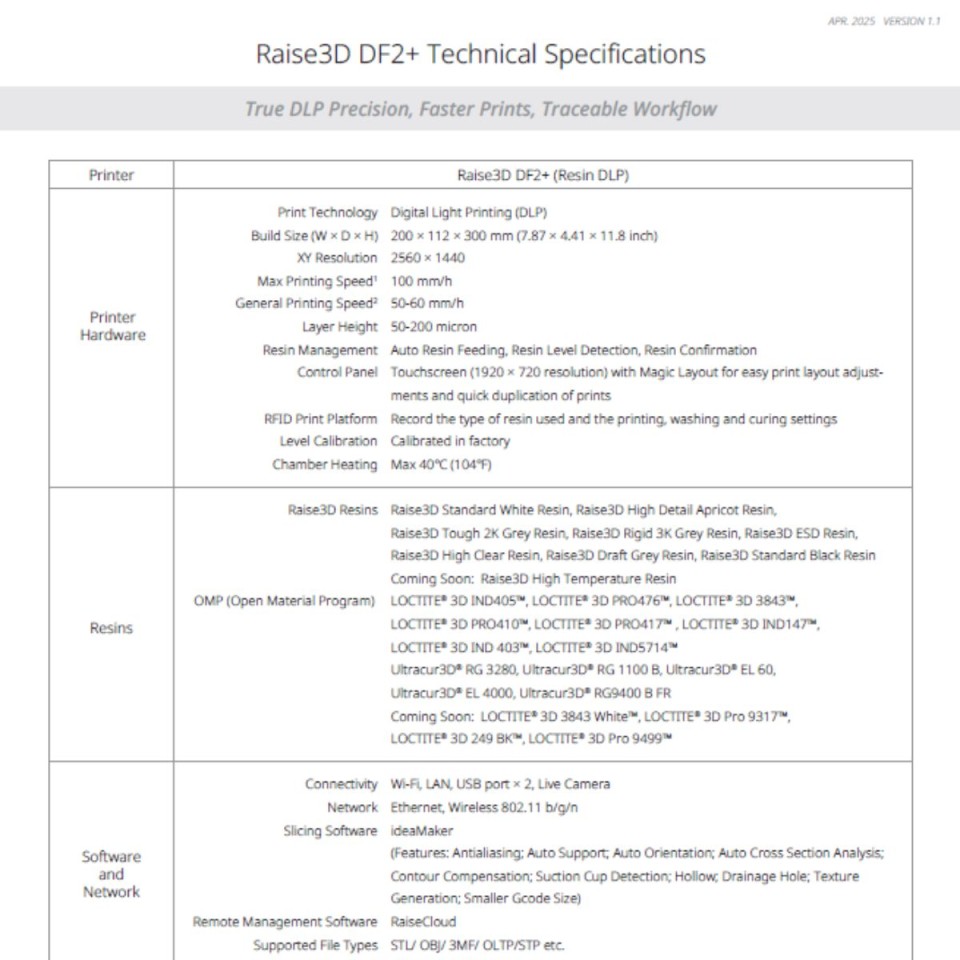

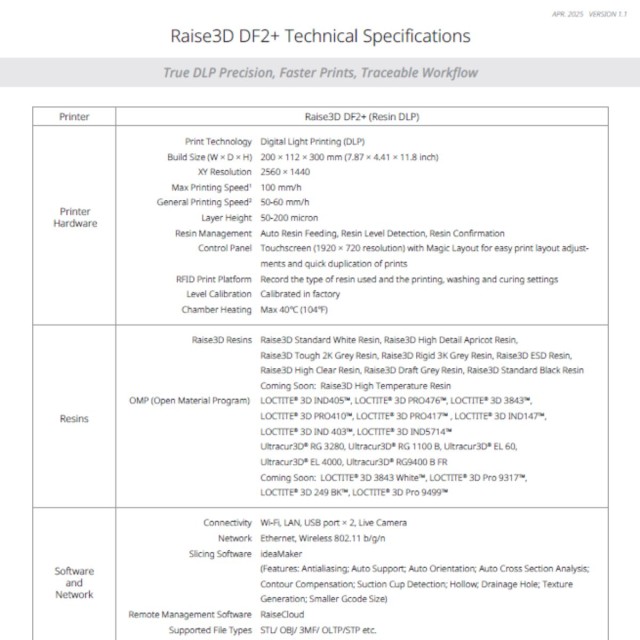

The Raise3D DF2+ is an advanced Digital Light Processing (DLP) resin 3D printer designed for industrial-grade accuracy, reliability, and high throughput. It combines cutting-edge optical technology with a comprehensive ecosystem to optimize prototyping, tooling, and small-batch production workflows.

Building on the success of the original DF2, the DF2+ incorporates a more powerful and durable light engine, boosting print speed by 20%. With a large build volume and true DLP technology, it ensures consistent layer curing and fine detail resolution for complex geometries, meeting evolving industrial demands.

The DF2+ features industrial-grade components including Texas Instruments’ DMD chips and precision optical films from Schott Germany, resulting in superior accuracy and uniform light intensity across the build platform. Its Air-Peel technology significantly reduces peeling forces, enabling reliable printing of large or delicate parts while extending component lifespan.

Supporting a broad resin portfolio through Raise3D’s Open Material Program (OMP), DF2+ offers users flexibility to work with proprietary and third-party resins tailored for high-impact, fire-retardant, electrical safety, or biocompatible applications. This versatility fulfills the needs of diverse industries such as automotive, aerospace, medical, consumer goods, and electronics.

Technical Specifications:

Build Volume: 200 × 112 × 300 mm

Layer Height: 50-200 microns

Chamber Heating: Max 40℃

Max Printing Speed: 100 mm/h

The DF2+ leverages Texas Instruments’ industrial-grade DMD chips and high-transparency optical films to deliver uniform, sharp layer curing. This ensures exceptional accuracy and detail fidelity, particularly for complex geometries, making it ideal for high-precision applications like dental models and intricate prototypes.

With a more powerful light engine, the DF2+ achieves print speeds up to 100 mm/h, approximately 20% faster than its predecessor. This acceleration enables rapid prototyping and small batch production, helping designers and engineers iterate more quickly without sacrificing print quality.

The DF2+ supports a wide variety of proprietary and third-party resins, including high-impact, biocompatible, fire-retardant, and electrical safety materials. This flexibility allows users across industries to tailor their materials selection to specific functional or regulatory requirements.

Equipped with RFID technology, the DF2+ automatically detects resin type, adjusts print parameters, and manages post-processing workflows with integrated DF Wash and DF Cure units. This reduces manual intervention, minimizes setup errors, and ensures consistent batch-to-batch print results.

The Air-Peel technology significantly lowers peeling forces during layer separation, reducing mechanical stress on prints and extending consumable lifetimes. This results in higher print success rates and enables reliable production of large or delicate models.

Raise3D’s DF2+ integrates with a suite of post-processing tools — washing, curing, finishing — and software for a seamless manufacturing workflow. This ecosystem enhances throughput, quality control, and operational efficiency, making it suitable for industrial production environments.

Accelerate design iterations with high-detail, mechanically robust resin parts that mimic final materials.

Produce durable and precise manufacturing aids and fixtures for assembly lines and quality control.

Print highly detailed, color-ready components for market testing and small-scale production runs.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy