3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Raise3D E3 excels as a user-friendly yet powerful desktop 3D printer optimized for specialist users requiring multi-material capabilities. Featuring independent dual extrusion technology, it allows the simultaneous printing of different materials or colors with flawless transitions. By combining large build volume and precise mechanics, it supports rigorous industrial applications with ease.

At the heart of the Raise3D E3 lies its independent dual extrusion (IDEX) system, making it capable of complex multi-material and color prints, including soluble support materials for intricate geometries. The printer supports a wide selection of filaments, from PLA and ABS to advanced composites like carbon fiber- and glass-filled filaments, opening doors for versatile applications across industries.

The large build volume of 330 × 240 × 240 mm accommodates sizable prototypes or batch manufacturing of small parts. The E3 is engineered for industrial reliability, with features such as a helical gear extrusion system for consistent filament feeding, closed-loop filament monitoring, and a heated, removable flexible build plate for easy print removal.

With an intuitive touchscreen interface, cloud connectivity, and seamless software integration through Raise3D’s ideaMaker slicer, E3 fosters productivity and precision. The printer’s sturdy design ensures minimal maintenance while delivering consistent, high-resolution output essential for engineering, design, and small-scale production workflows.

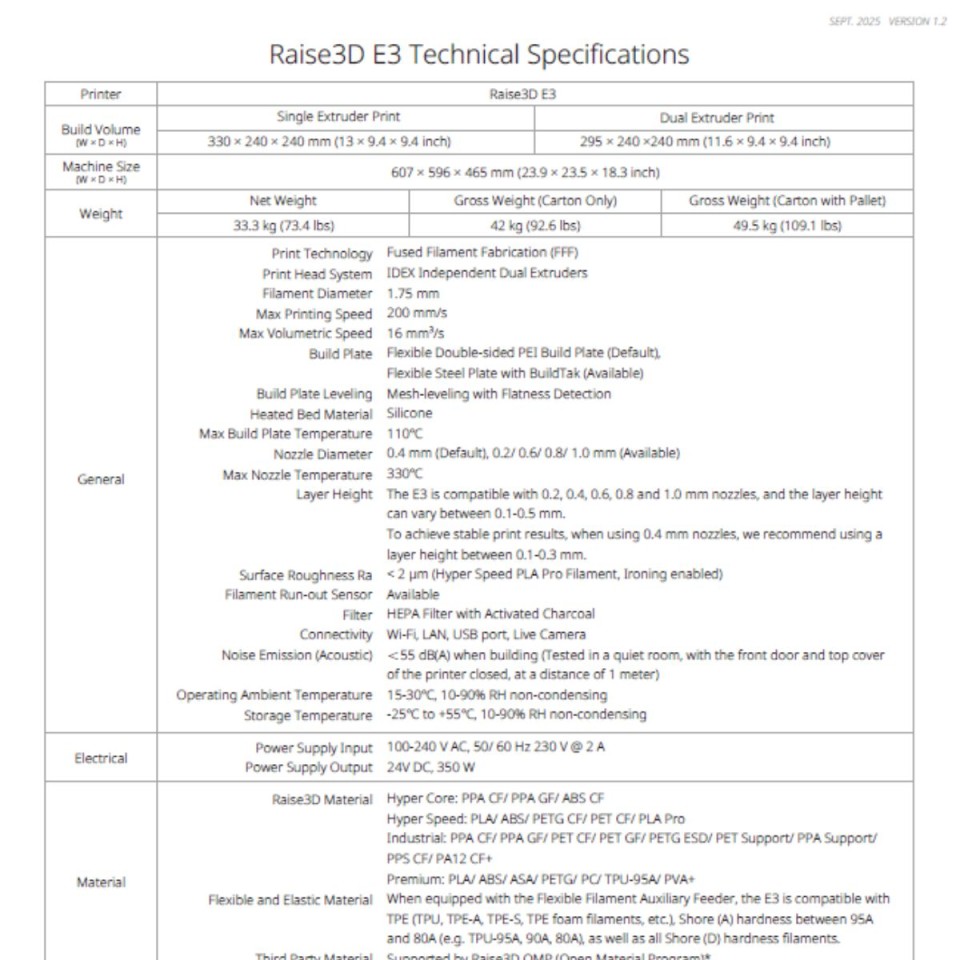

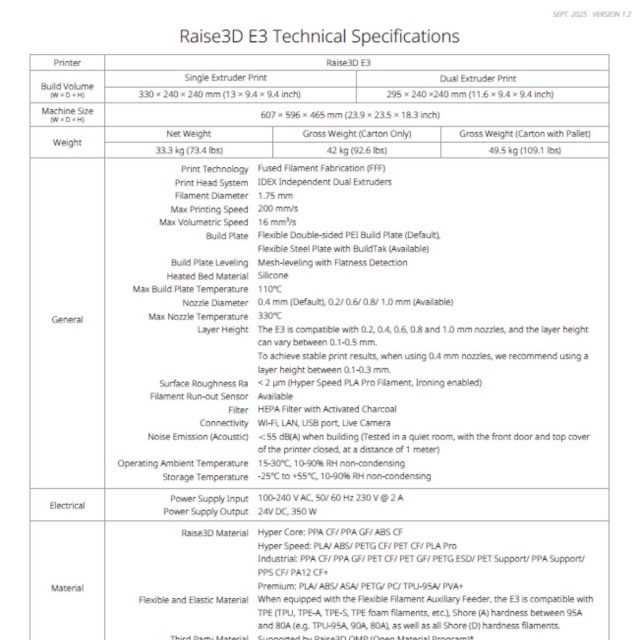

Technical Specifications:

Build Volume: 330 × 240 × 240 mm (single extruder), 295 × 240 × 240 mm (dual extruder)

Print Head System: Independent Dual Extruder (IDEX)

Layer Resolution: 10 to 250 microns

Nozzle Diameter: 0.4 mm (standard), interchangeable

The IDEX system allows the two extruders to operate independently, enabling simultaneous printing of different materials or colors, reducing print time and expanding creative possibilities. It also supports duplication and mirror modes to double production speed or create symmetrical parts efficiently.

The E3 supports a broad range of filaments including PLA, ABS, TPU, nylon, and composite materials like carbon fiber and glass-filled filaments. This versatility lets users prototype or produce functional parts across industries with diverse material requirements.

With a build volume of 330 × 240 × 240 mm, the E3 accommodates sizable parts or multiple smaller parts per run. The removable heated bed simplifies print removal and improves build surface adhesion, streamlining post-processing and reducing downtime.

The Flexible Filament Auxiliary Feeder on the Raise3D E3 enhances printing speed by providing advanced feeding and buffering capabilities specifically optimized for flexible materials such as TPU and TPE. This auxiliary system stabilizes filament delivery, minimizing jams and print failures while enabling the E3 to achieve high-speed printing at up to 200 mm/s with flexible filaments.

Equipped with advanced mechanics such as a helical gear extrusion system and automatic 9-point bed leveling to different surface variations, the E3 delivers consistent, high-resolution prints. Features like filament run-out sensors and power-loss recovery ensure stable long-run operations with minimal print failures.

The 7-inch touchscreen and seamless integration with Raise3D’s ideaMaker software simplify printer control from setup to print completion. Cloud connectivity allows remote monitoring and management, boosting operational efficiency.

Engineered for continuous production, the E3’s robust chassis and components reduce wear and maintenance requirements. The E3 is equipped with two material storage slots with desiccant to keep stored filaments dry, eliminating dimensional distortion and moisture-related print defects caused by continuous high-temperature drying

Engineers can quickly create durable prototype parts to test fit, form, and function before mass production.

Manufacture lightweight, high-strength components by printing with carbon fiber or glass-filled filaments for aerospace or automotive uses.

Ideal for STEM labs and academic institutions to explore advanced materials and multi-material print capabilities.

Produce custom tooling, jigs, fixtures, or low-volume end-use parts directly from the desktop printer, reducing lead times.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy