3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

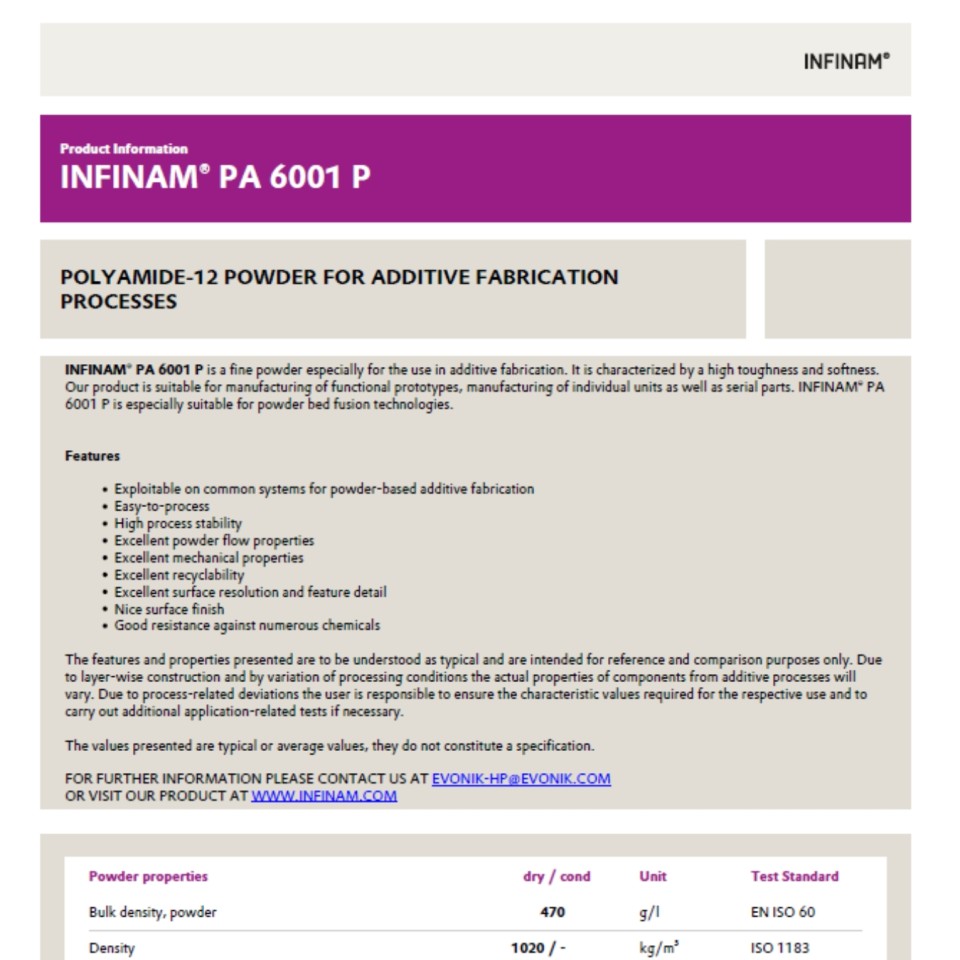

INFINAM PA 6001 P is a premium nylon powder developed for additive manufacturing, especially suitable for powder bed fusion technologies. Renowned for its high strength, chemical resistance, and food contact safety, it is ideal for creating durable, functional parts that withstand harsh conditions, making it a versatile choice for various industrial sectors.

INFINAM PA 6001 P represents the latest innovation in nylon powders for 3D printing, combining the best features of polyamides to meet rigorous industrial standards. As a food contact-acceptable material, it ensures safety and compliance for use in medical, automotive, aerospace, and even food industry applications. Its formulation based on polyamide 12 (PA12) grants it excellent impact resistance, low water absorption, and high-temperature stability, making it suitable for parts exposed to demanding environments.

This nylon powder also excels in processability, providing consistent high-quality output with excellent surface finish and dimensional stability. Its inherent UV resistance and high mechanical strength make it an ideal choice for functional prototypes, serial production of parts, and complex geometries. The low water uptake rate (less than 3%) not only enhances its processability but also ensures the durability of the printed parts over time, reducing warping and deformation in various environments.

Whether used in laser sintering or similar technologies, INFINAM PA 6001 P delivers reliable performance, enabling manufacturers to produce parts with high precision, durability, and excellent surface properties. Its natural color supports post-processing and dyeing, offering further customization options for branding or aesthetic requirements.

Technical Information:

Heat Deflection Temperature: Approximately 195 °C

Water Absorption: Less than 3%

Application Technology: SLS, other powder fusion methods

Food Contact Approved: Yes

INFINAM PA 6001 P exhibits superior mechanical properties, including high tensile strength and excellent impact resistance. This makes it ideal for producing durable and robust parts that perform reliably under mechanical stress and impact conditions in demanding industrial applications.

The material is highly resistant to a broad range of chemicals, oils, and greases, which ensures that parts maintain integrity and functionality even in harsh chemical environments. This chemical durability makes it perfect for automotive, aerospace, and industrial applications where exposure to oils and solvents is common.

With its low water uptake rate of less than 3%, parts printed with INFINAM PA 6001 P exhibit excellent dimensional stability and reduced risk of warping or swelling due to moisture. This characteristic also improves printing consistency and part longevity, ideal for precision components that demand tight tolerances.

INFINAM PA 6001 P holds food contact compliance, making it safe for applications involving direct or indirect contact with food substances. This advantage extends its usability to medical devices, food processing equipment, and packaging components, where regulatory safety standards are critical.

The material demonstrates strong resistance to ultraviolet radiation and sustained high temperatures (with heat deflection temperature around 195 °C). Such properties allow the production of parts that can be used in outdoor environments or under thermal stress without degradation over time.

Durable structural parts and prototypes that require high impact resistance and chemical stability. INFINAM PA 6001 P allows for complex geometries with excellent surface finish, ideal for testing and functional use.

Lightweight, high-strength components that withstand exposure to high temperatures and chemicals. Its precise dimensional stability ensures parts meet strict aerospace standards.

Custom surgical tools and components that require biocompatibility and safety, benefiting from the food contact approval and chemical resistance of the material.

Food processing parts and molds that benefit from the material’s safety profile and durability, enabling repeat use in demanding environments.

Fill up the form below and we will send you the material data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Call us or send us an email and we will be happy to help you.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy