3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

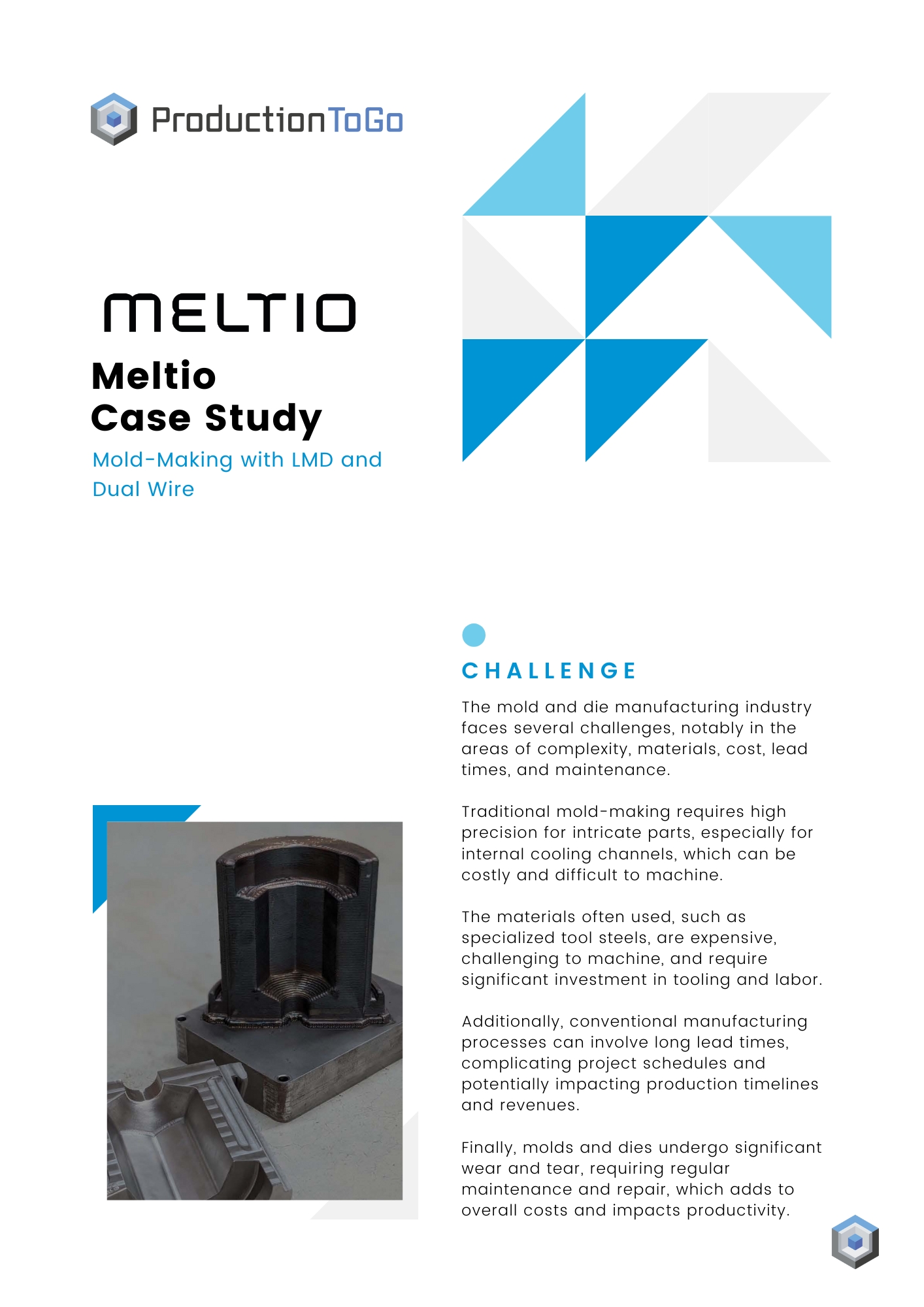

The die and mold industry faces several challenges, particularly in the areas of complexity, materials, costs, lead times and maintenance. Traditional mold making requires high precision for complicated parts, especially with internal cooling channels, which can be costly and difficult to machine. The commonly used materials, such as special tool steels, are expensive, difficult to machine and require significant investment in tools and labor. Furthermore, conventional manufacturing processes can involve long lead times, making project planning more difficult and potentially impacting production deadlines and revenues. Find out how Meltio's LMD technology solves these problems and increases efficiency in this application!

Fill up the form below and we will send you the use case by e-mail.

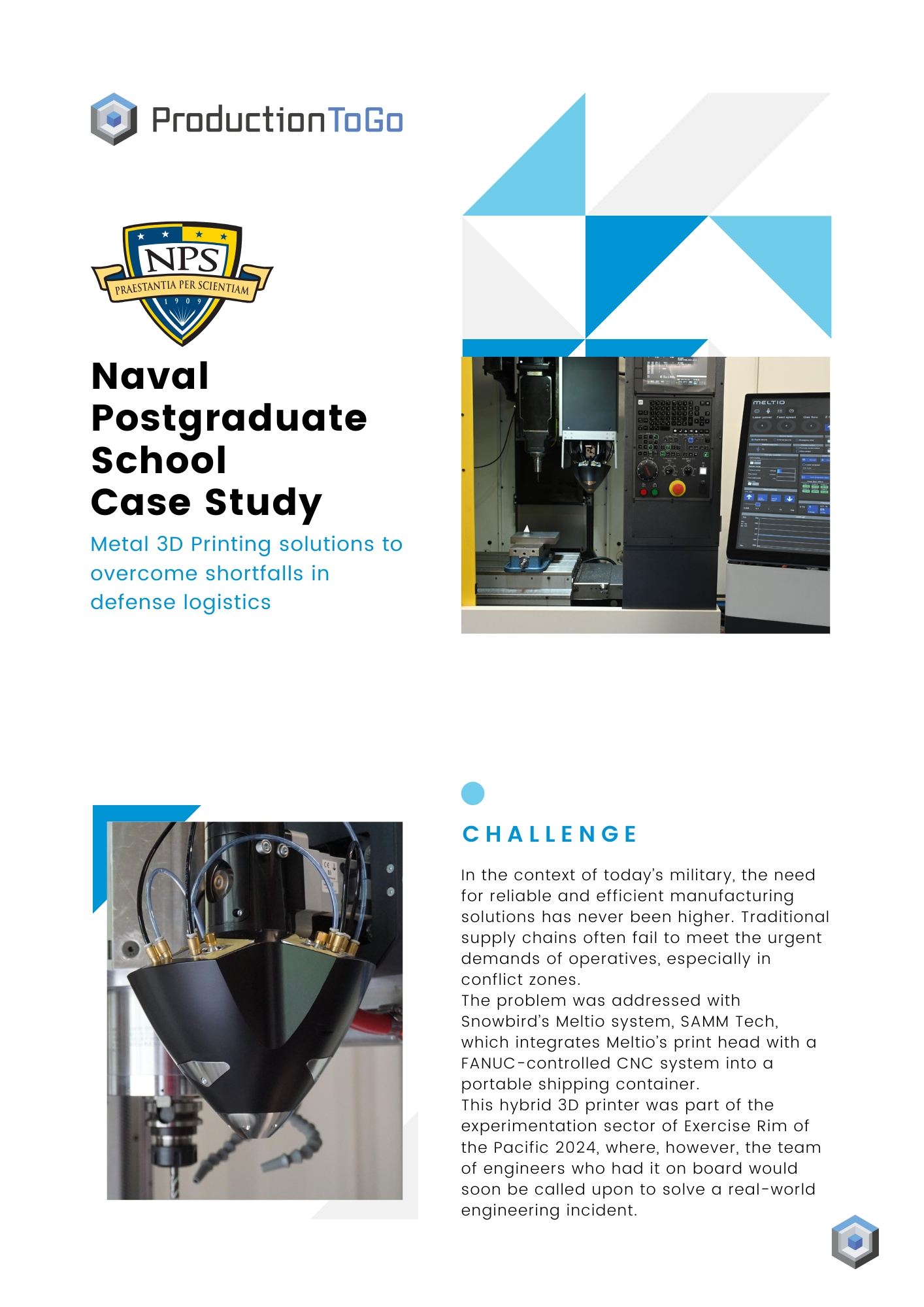

In the context of today's military, the need for reliable and efficient manufacturing solutions has never been greater. Traditional supply chains often cannot meet the needs of the forces, especially in conflict areas. The problem was addressed with the Meltio system from Snowbird, SAMM Tech, which integrates the Meltio print head with a FANUC-controlled CNC system in a portable shipping container. This hybrid 3D printer was part of the experimentation area of the Rim of the Pacific 2024 exercise, where the engineering team that had it on board was soon called upon to solve a real technical incident. Find out how the Meltio solution was able to resolve this incident in this case study!

Fill up the form below and we will send you the use case by e-mail.

Unverferth Manufacturing was struggling with high costs and wear problems with conventionally manufactured injection moulded blades – critical parts that were exposed to abrasion from soil and chemicals. Casting and machining presented challenges such as deformation, long lead times and complex features. To ensure long equipment life and reduce costs, Unverferth sought an optimised, more efficient redesign.

Fill up the form below and we will send you the use case by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy