3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

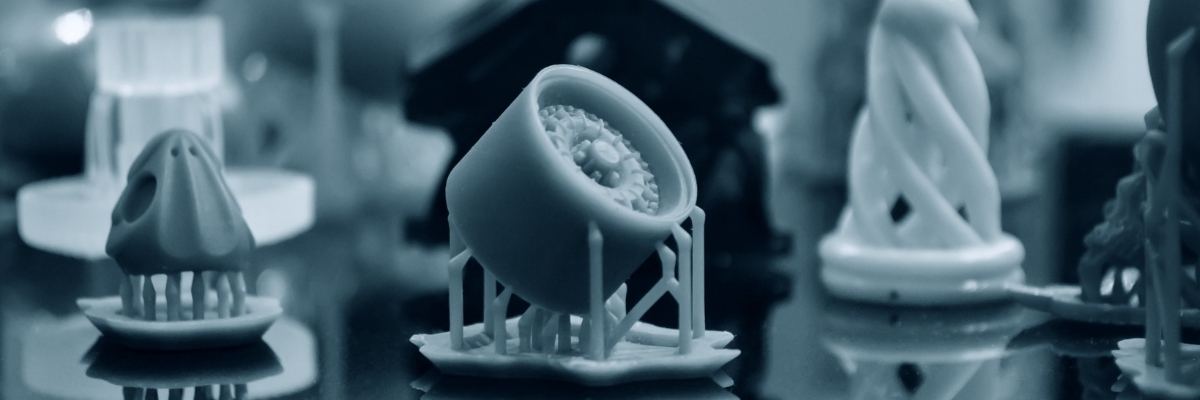

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

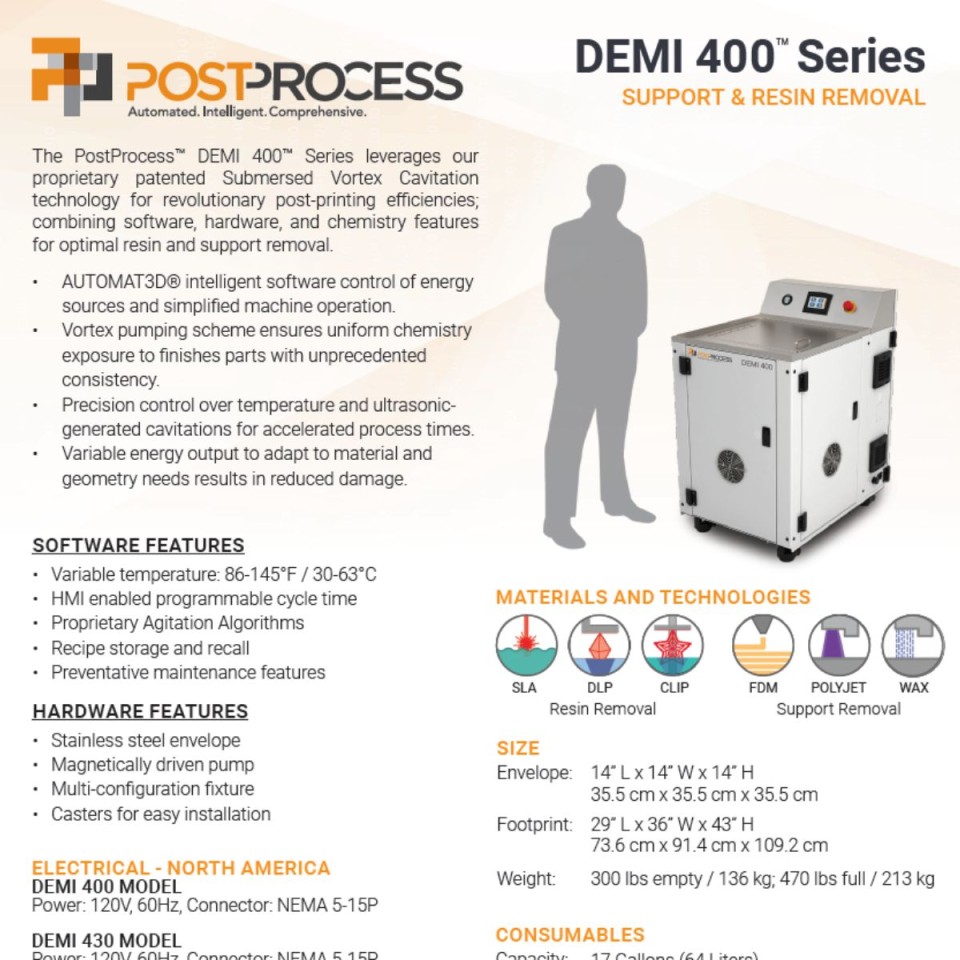

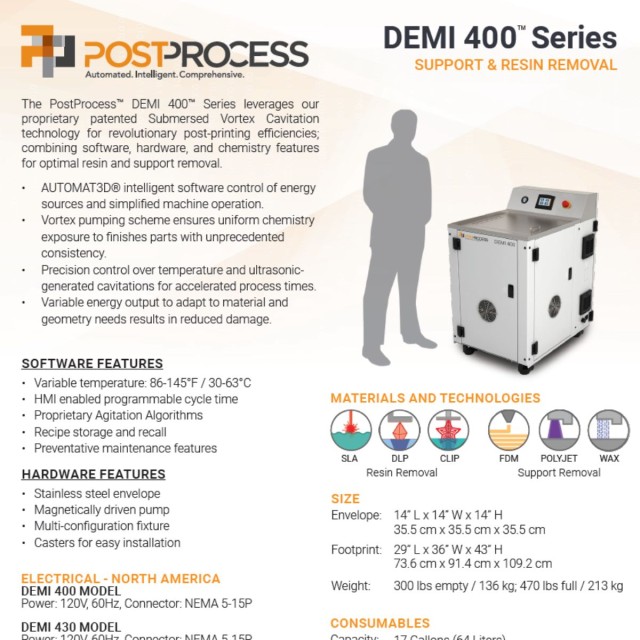

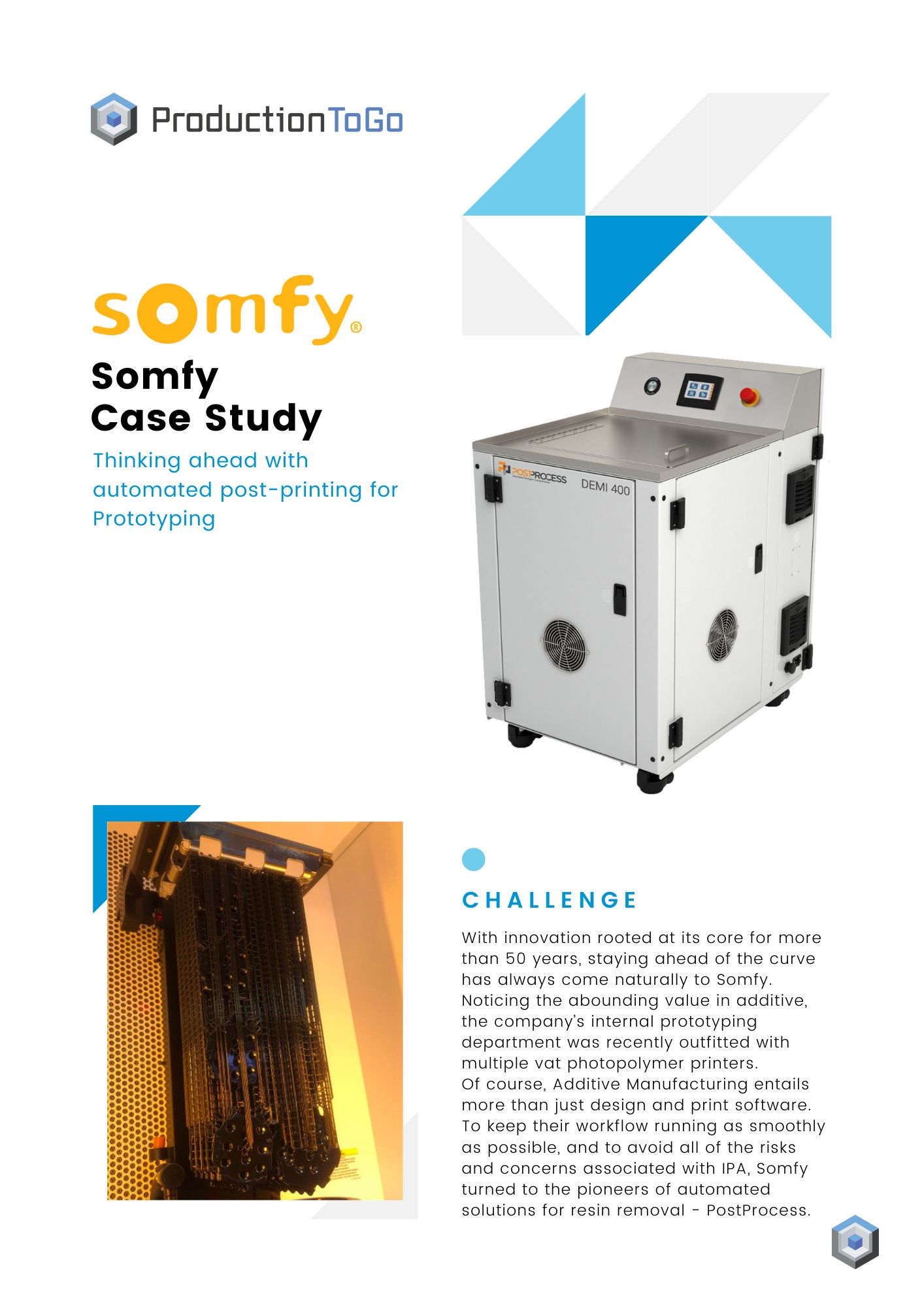

With innovation rooted at its core for more than 50 years, staying ahead of the curve has always come naturally to Somfy. Noticing the abounding value in additive, the company’s internal prototyping department was recently outfitted with multiple vat photopolymer printers. Of course, Additive Manufacturing entails more than just design and print software. To keep their workflow running as smoothly as possible, and to avoid all of the risks and concerns associated with IPA, Somfy turned to the pioneers of automated solutions for resin removal - PostProcess.

Fill up the form below and we will send you the use case by e-mail.

3D printing technology plays a crucial role in the Nexus Dental Lab workflow, enabling the company to produce higher quality dental restorations and models more efficiently than ever before. However, they faced several challenges with resin removal using isopropyl alcohol (IPA), as this process was not only time-consuming and inconsistent, but also unsustainable and dangerous for employees. Discover how the DEMI 400™ was able to solve this problem in this use case!

Fill up the form below and we will send you the use case by e-mail.

Schollmeier Dental is a renowned dental laboratory based in Hannover, Germany, and employs a team of around 80 professionals. As Schollmeier Dental looked further into 3D printing technology, the challenge of efficient post-processing became apparent. Discover how Schollmeier Dental used the DEMI 400™ for this in this use case!

Fill up the form below and we will send you the use case by e-mail.

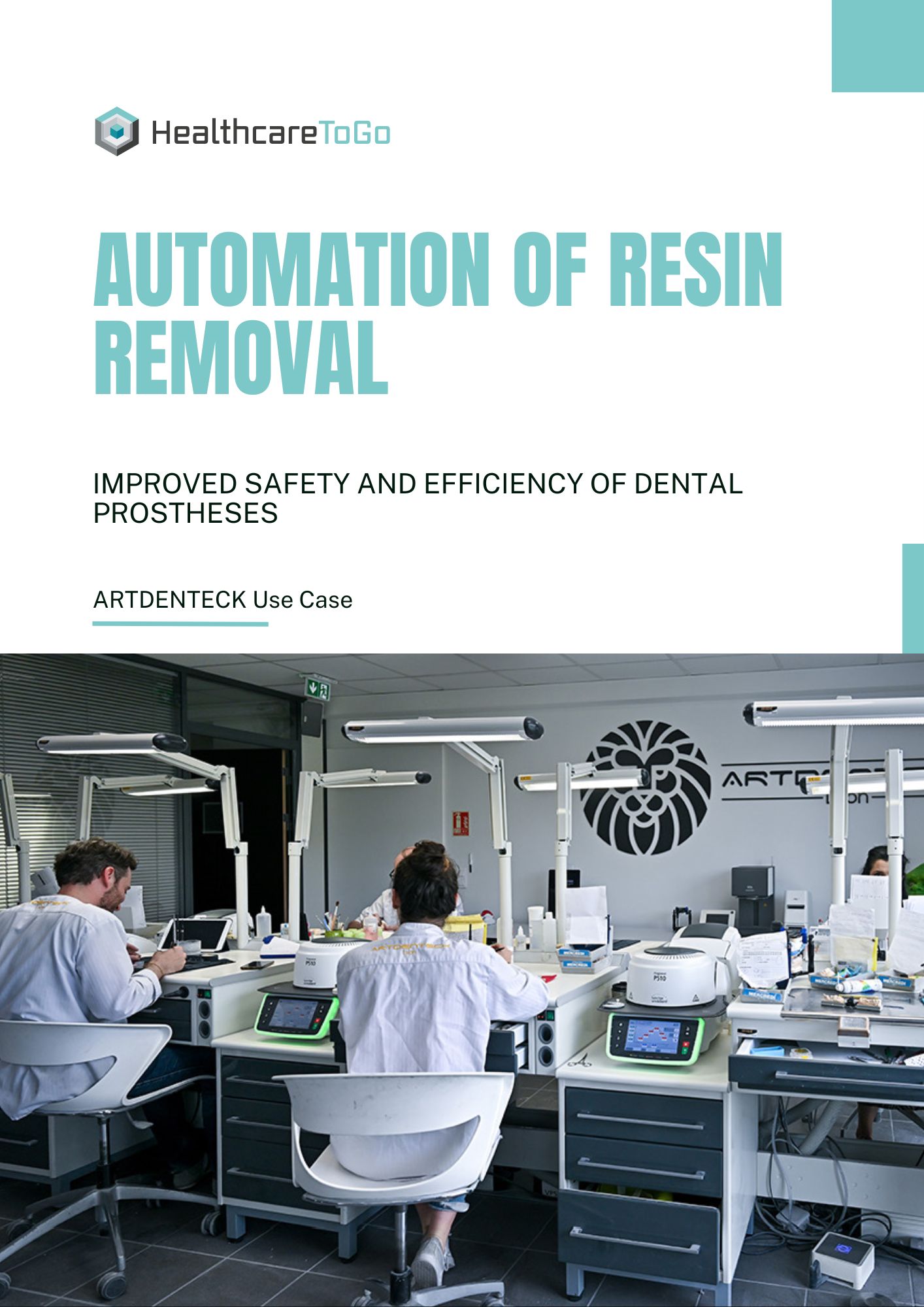

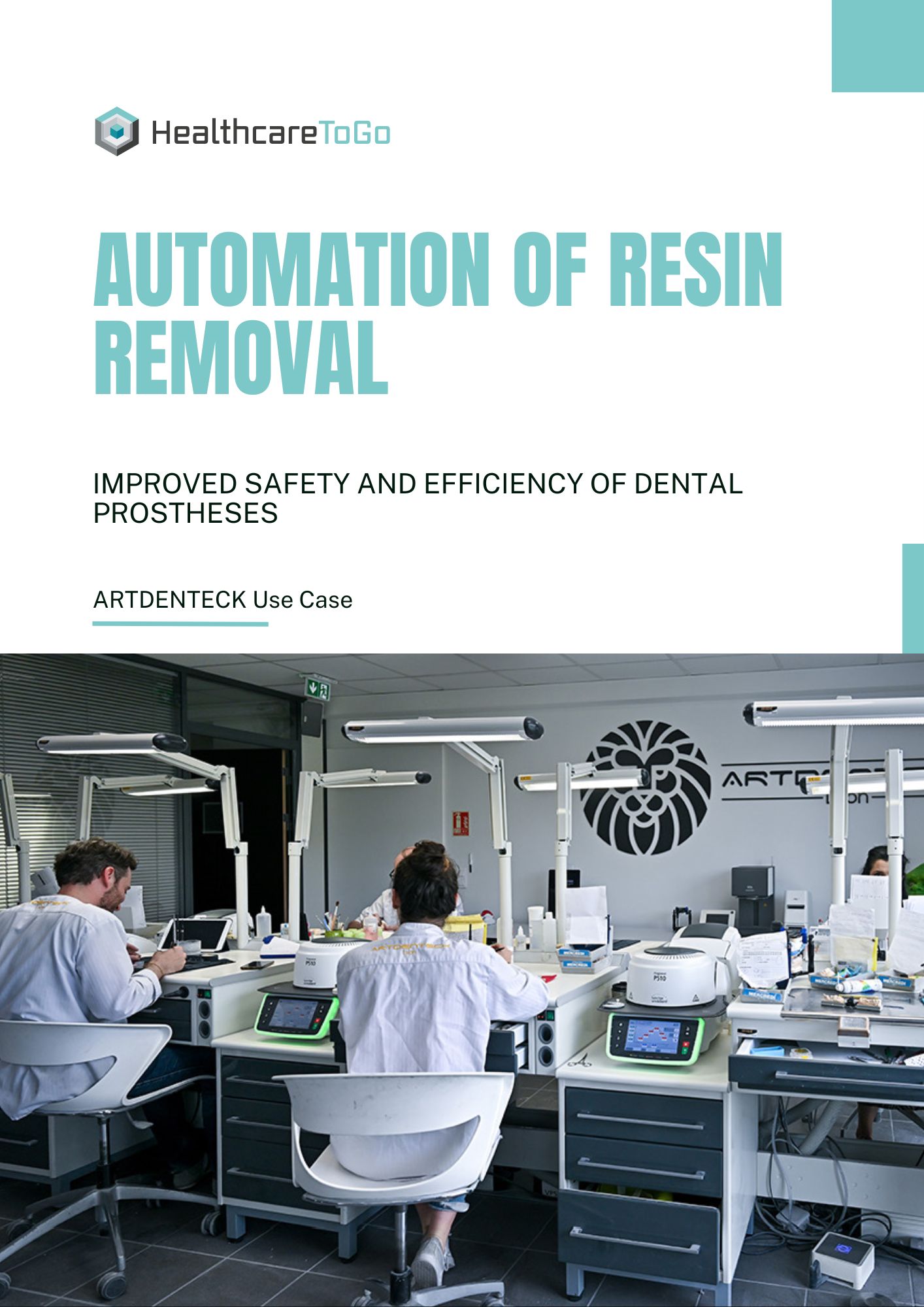

ARTDENTECK is a French dental laboratory specialising in high-quality prostheses, committed to craftsmanship, precision and fast delivery. However, cleaning 3D-printed dental indications proved to be a time-consuming challenge. Find out how the DEMI 400™ solves this challenge!

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

On-demand Webinar |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy