3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

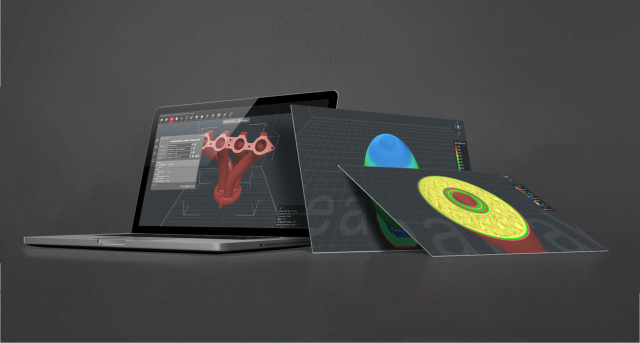

The Raise3D RMS220 is a sophisticated SLS 3D printer designed for high-speed, high-volume manufacturing that can help you achieve industrial-scale productivity and accuracy. Your doorway to flawless batch production, intricate geometries, and end-use parts—all with unparalleled efficiency—is the RMS220, which boasts a powerful 75 W fiber laser, quick material changes, and remarkable precision.

The Raise3D C220-P is a specialized post-processing station made to integrate easily with the Raise3D RMS220 SLS printer. Powder preparation, part extraction, and powder recovery are its primary functions. Because of its small size (1384 x 823 x 1740 mm, including the control panel and tower light), the C220-P can be used in a variety of manufacturing settings where space efficiency is crucial.

By incorporating semi-automated procedures, this cleaning station significantly lowers manual labor and boosts operating efficiency. Within a single, easy-to-use system, the C220-P allows users to retrieve produced parts, recover and segregate unwanted powder, and prepare the powder for reuse after printing. Only 20 to 45 minutes of work are needed for each print cycle, and one operator may process more than 50 kg of components in a shift, greatly increasing production.

With its large build volume of 220 × 220 × 350 mm, the Raise3D Build Unit 220 is perfect for both prototype and end-use manufacturing. It enables customers to print large parts or densely packed quantities in a single run. The quick-detach system built into the Build Unit 220 allows for quick material changes in as little as 45 minutes, greatly minimizing downtime and enhancing operating flexibility.

The Build Unit 220's external cooling capabilities is one of its best features. The build unit may be taken out of the printer and cooled to below 100°C in about 30 minutes after a print job is finished. This allows the RMS220 to start the next print right away using a second build unit.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy