3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Scorpion Security Products is a US company that specializes in asset protection, particularly for phones, tablets, and wearables at storefronts, with the aim of reducing theft. They needed a solution which enables them to quickly iterate and improve their designs in streamlining their processes. A change to an in-house production was also a long time goal of the company. Until they switched to 3D printing with the Raise3D E2 and Pro3 they outsourced their prototyping completely, which was not only costly but also very time consuming.

Fill up the form below and we will send you the use case by e-mail.

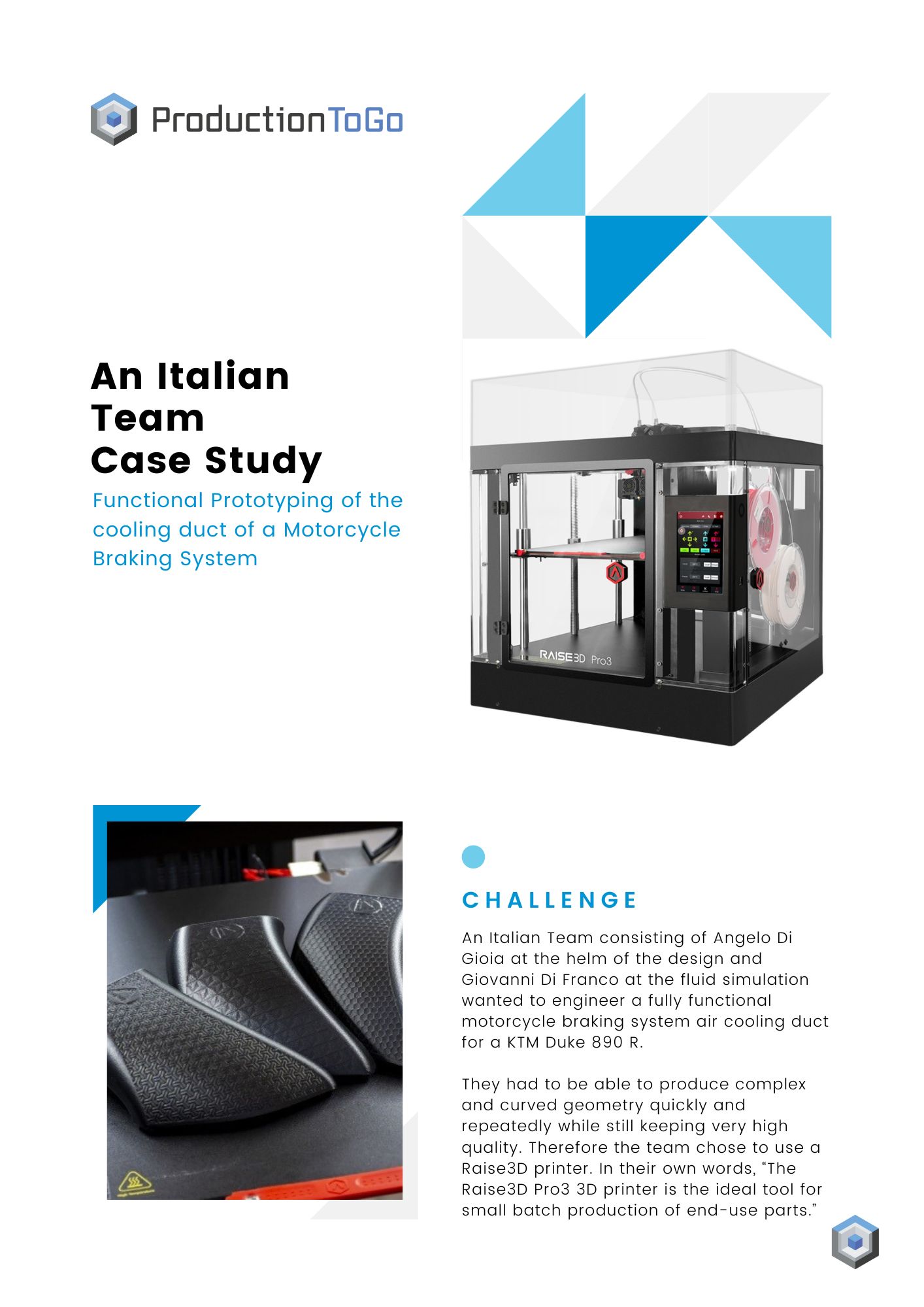

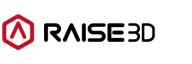

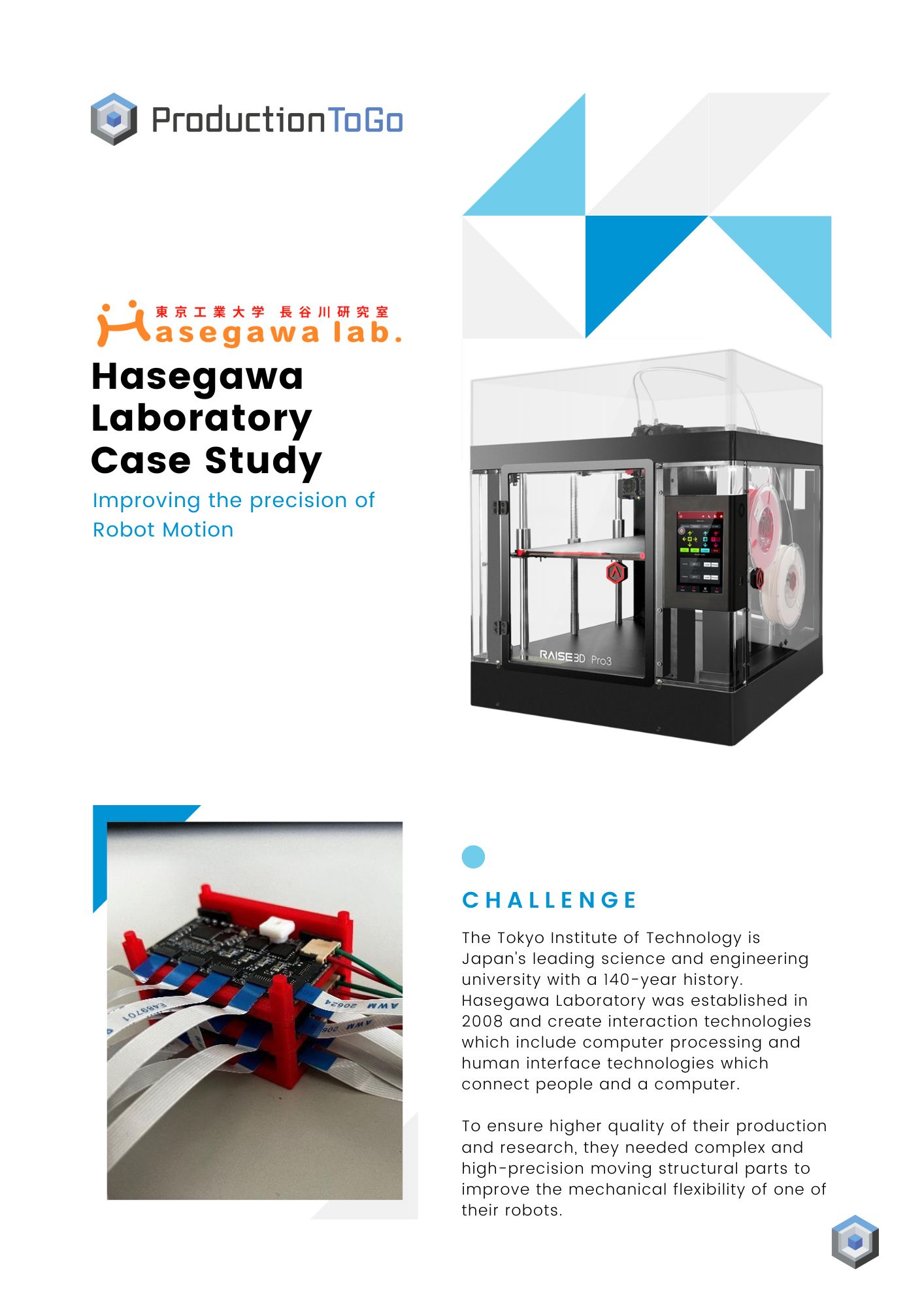

An Italian Team consisting of Angelo Di Gioia at the helm of the design and Giovanni Di Franco at the fluid simulation wanted to engineer a fully functional motorcycle braking system air cooling duct for a KTM Duke 890 R. They had to be able to produce complex and curved geometry quickly and repeatedly while still keeping very high quality. Therefore the team chose to use a Raise3D printer. In their own words, “The Raise3D Pro3 3D printer is the ideal tool for small batch production of end-use parts.”

Fill up the form below and we will send you the use case by e-mail.

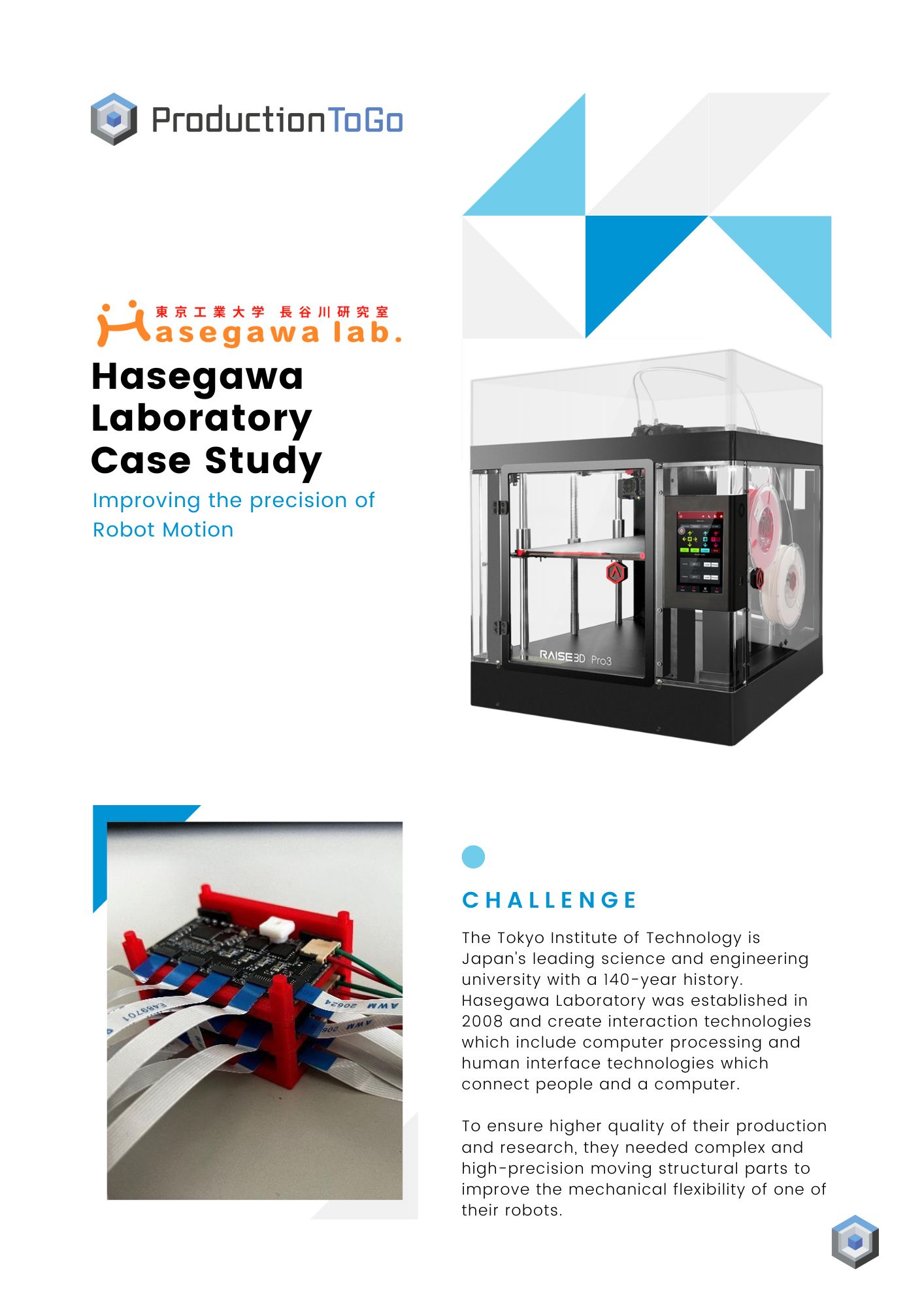

The Tokyo Institute of Technology is Japan's leading science and engineering university with a 140-year history. Hasegawa Laboratory was established in 2008 and create interaction technologies which include computer processing and human interface technologies which connect people and a computer. To ensure higher quality of their production and research, they needed complex and high-precision moving structural parts to improve the mechanical flexibility of one of their robots.

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy