3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Scorpion Security Products is a US company that specializes in asset protection, particularly for phones, tablets, and wearables at storefronts, with the aim of reducing theft. They needed a solution which enables them to quickly iterate and improve their designs in streamlining their processes. A change to an in-house production was also a long time goal of the company. Until they switched to 3D printing with the Raise3D E2 and Pro3 they outsourced their prototyping completely, which was not only costly but also very time consuming.

Fill up the form below and we will send you the use case by e-mail.

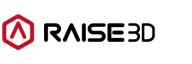

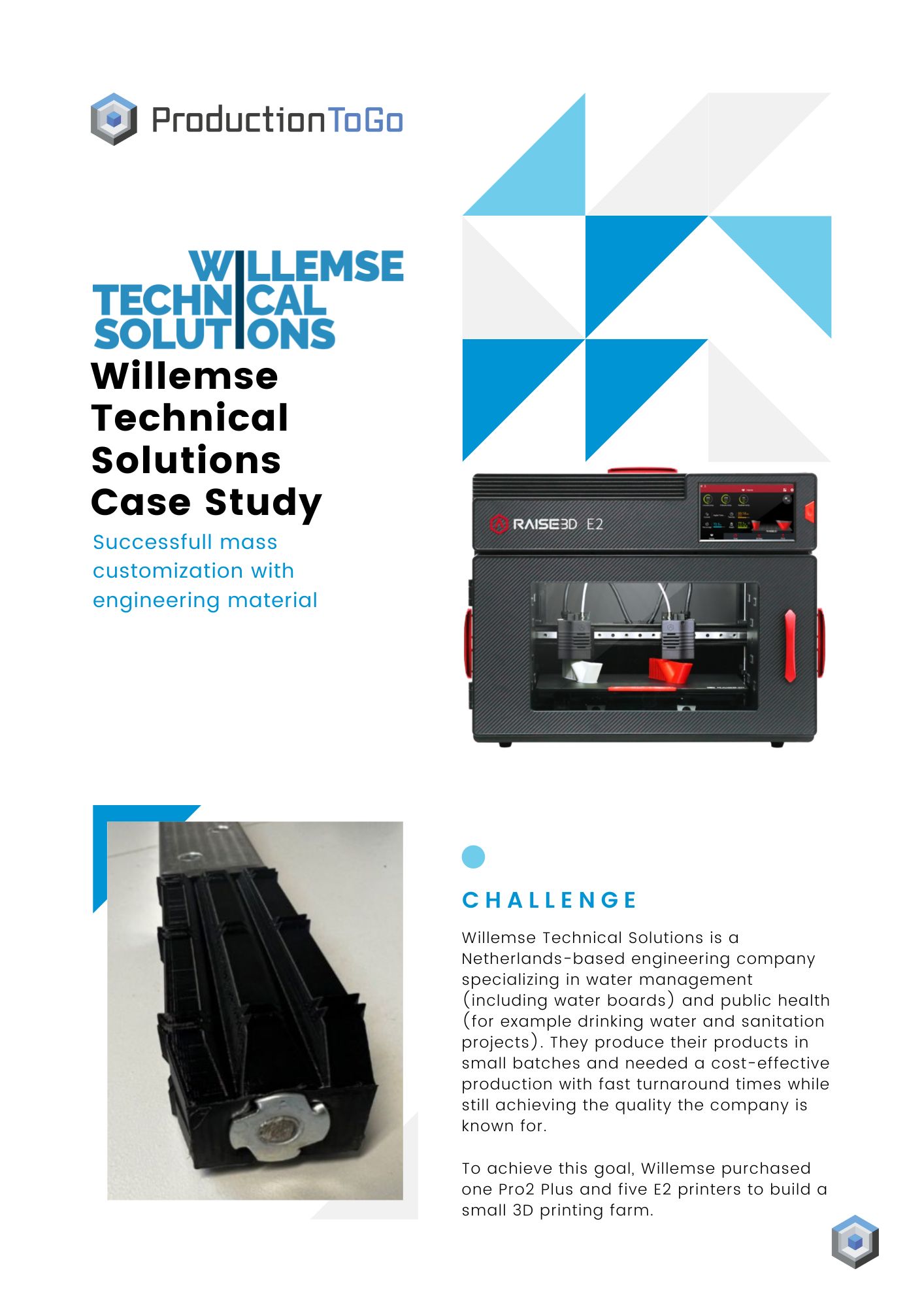

Willemse Technical Solutions is a Netherlands-based engineering company specializing in water management (including water boards) and public health (for example drinking water and sanitation projects). They produce their products in small batches and needed a cost-effective production with fast turnaround times while still achieving the quality the company is known for. To achieve this goal, Willemse purchased one Pro2 Plus and five E2 printers to build a small 3D printing farm.

Fill up the form below and we will send you the use case by e-mail.

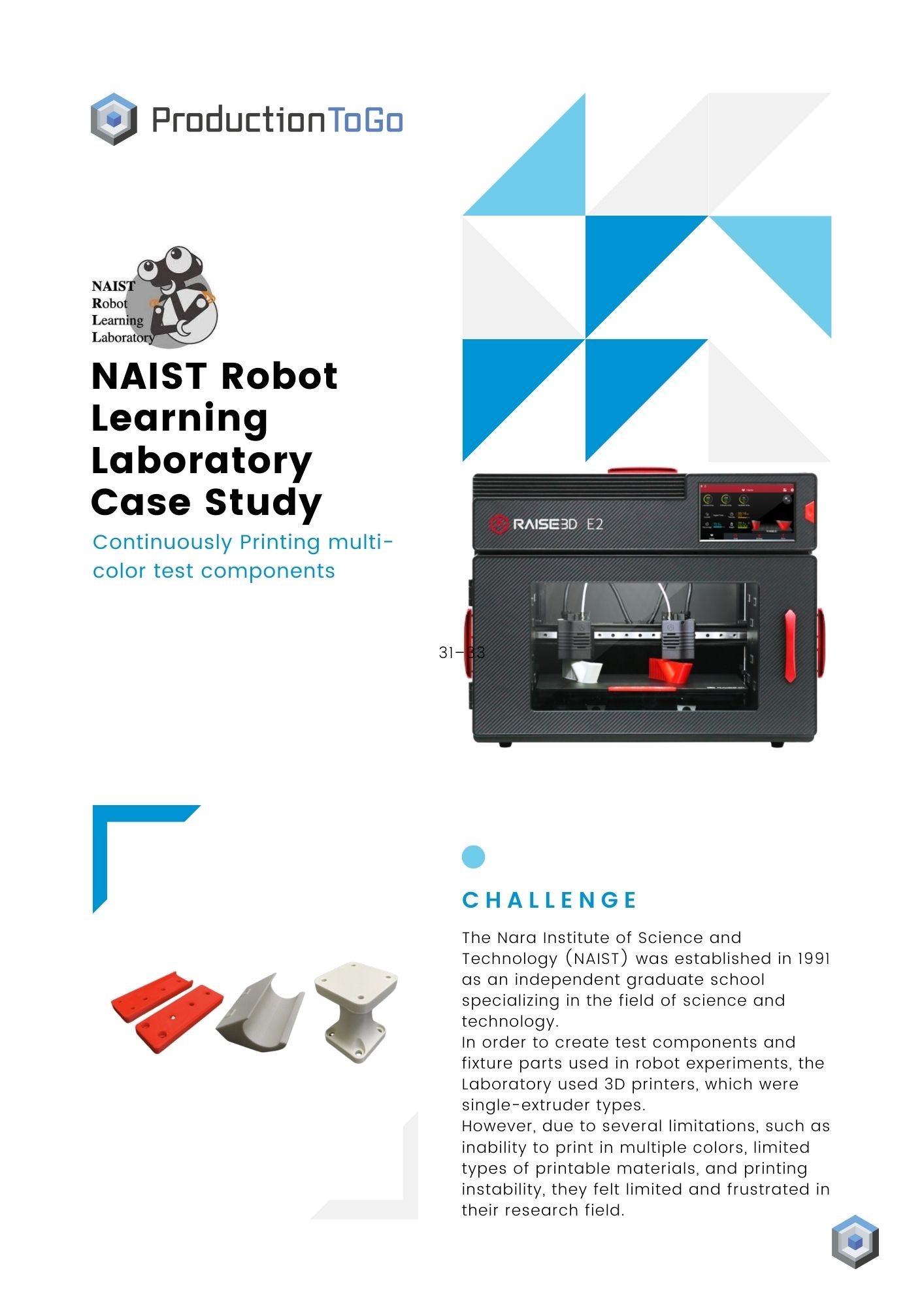

The Nara Institute of Science and Technology (NAIST) was established in 1991 as an independent graduate school specializing in the field of science and technology. In order to create test components and fixture parts used in robot experiments, the Laboratory used 3D printers, which were single-extruder types. However, due to several limitations, such as inability to print in multiple colors, limited types of printable materials, and printing instability, they felt limited and frustrated in their research field.

Fill up the form below and we will send you the use case by e-mail.

3D printing allows for unparalleled precision, enabling the fabrication of shoes tailored to the unique contours of an individual’s feet. So, it is no surprise that this type of manufacturing has been developed and explored within the AM community. Crea3D, a Raise3D reseller based in Italy, and FastParts, an AM service company from within Crea3D’s ecosystem, developed the FuSa shoe, a custom sneaker with a range of unique properties.

Fill up the form below and we will send you the use case by e-mail.

Founded by Nicolas Fumel, Fumel3D specializes in crafting intricate models using cutting-edge technology. From real estate replicas to custom-designed furniture, the company caters to a diverse clientele seeking to visualize their architectural visions in three dimensions. Central to their operation is the meticulous planning that precedes manufacturing. Every detail is scrutinized, ensuring that the final product aligns seamlessly with the architect’s vision.

Fill up the form below and we will send you the use case by e-mail.

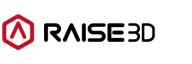

Sooley is a company based in Konstanz, Germany. The company’s CEO, Sanya Zillich, envisions a sustainable and health-conscious society and is dedicated to transforming the custom insole market. Sooley’s primary focus lies in the creation and online retailing of tailor-made orthopedic insoles. Through a unique mobile application, customers can have their feet accurately 3D scanned, giving them precise foot data to enable Sooley to create individualized and comfortable insoles.

Fill up the form below and we will send you the use case by e-mail.

|

|

On-demand Webinar |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy