3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

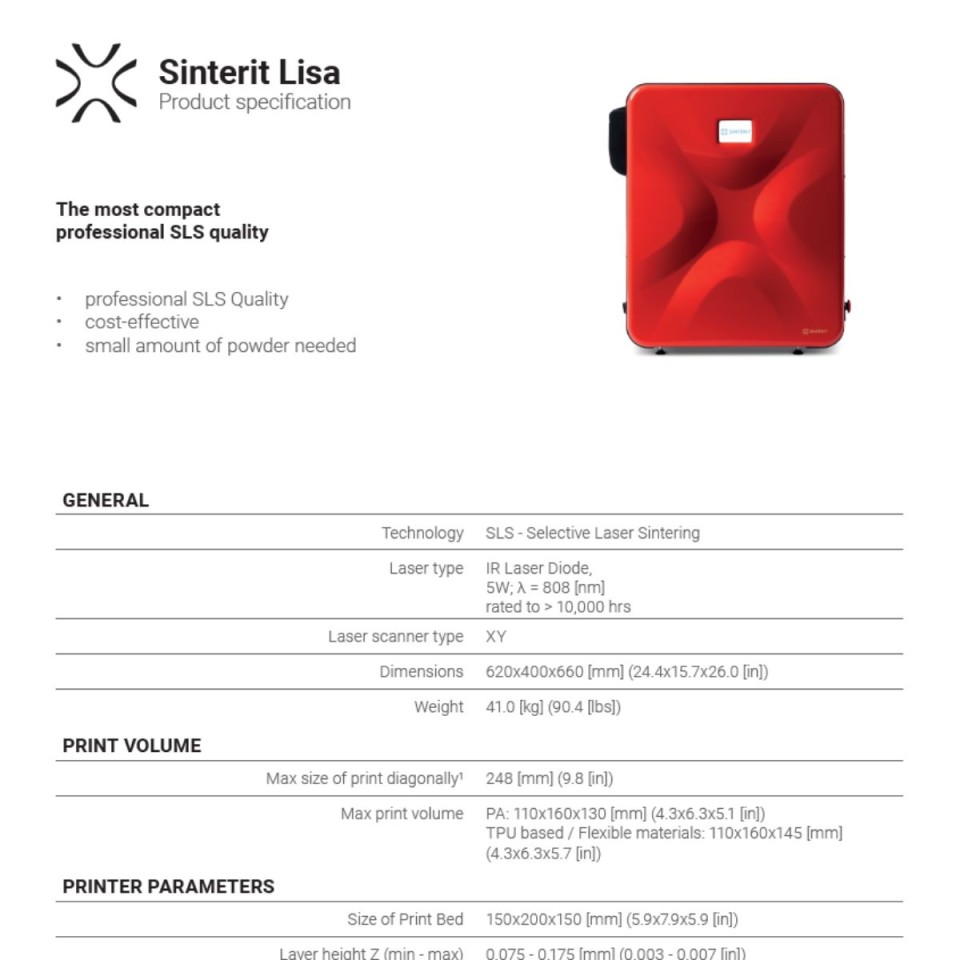

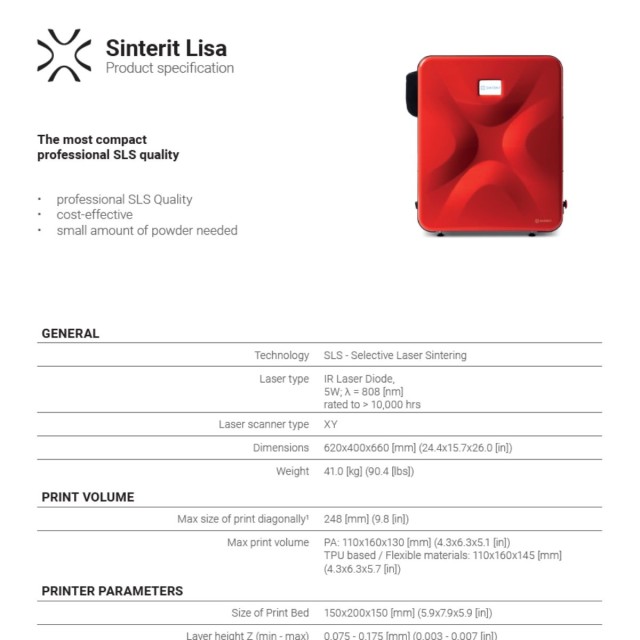

The Center for Innovation and Process Engineering Research (CIPER), a group inside the University of Greenwich, has a worldwide reputation on the implementation of 3D printing technologies for the development of pharmaceutical dosage forms and medical devices. They were looking for a technology that can print extruded or granulated powders loaded with drug substances and that would not depend on the development of printable filaments

Fill up the form below and we will send you the use case by e-mail.

The exoskeleton arm is a device that allows children to move hands, draw, play and express themselves – simply to do what kids love to do. The invention is extremely needed, especially by the children with SMA who are not able to move their legs, arms, hands without specialized external supportive devices. Sinterit wanted to create an affordable and easy to setup, dynamic support exoskeleton arm for kids, which is ready to use straight out of the box. The idea came from parents of children with SMA, who couldn’t find an adequate solution.

Fill up the form below and we will send you the use case by e-mail.

AM enables companies to return their production to local suppliers and even in-house AM hubs. This next evolution in manufacturing will disrupt the way products are distributed. Large distributors like Gautzsch will be the first to experience the disruption in manufacturing methods due to Additive Manufacturing on a large scale. Can the innovators at Gautzsch use Additive manufacturing to excel with new capabilities? Peter Benthues described how their in-house AM Lab is exploring the latest AM trends.

Fill up the form below and we will send you the use case by e-mail.

|

|

Watch the video |

|

|

Watch the video |

|

|

On-demand Webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy